Performance Pneus

University of Southern California, Top Fuel Workshop, 19 – 26 March 2012

The workshop will investigate how the often overlooked lineage of pneumatic systems in architecture can be injected with a new life through contemporary means of computational design, simulation and fabrication. Pneumatic systems have been explored for their structural effectiveness and deployability, but more often than not their environmental performance turned out to be quite problematic. Thus one of the critical aspects of this workshop is to broaden the performance range through the inclusion of environmental design criteria, for which the challenging climate of Southern California will serve as a real-world development laboratory.

The students participating in the workshop will investigate the inseparable relation between the form and performance of pneumatic systems through the development of full scale performative pneumatic prototypes based on the concurrent employment of the following three methods within each team:

Exploring Material Gestalt – Physically Computing Pneumatic Structures

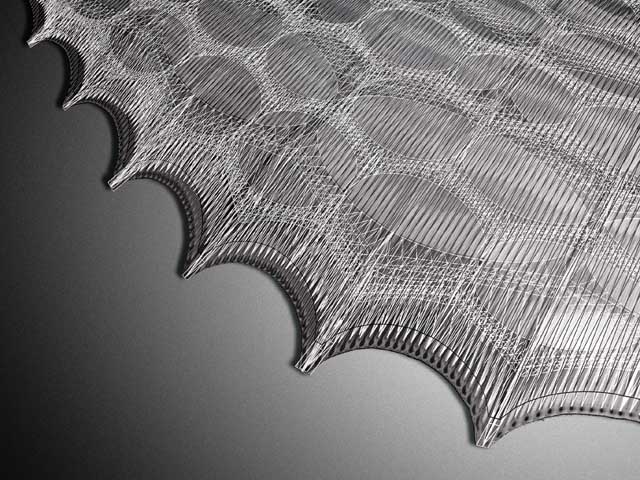

The shape of any pneumatic system results from the equilibrium state of material characteristics and air pressure differences. In other words, pneumatic systems physically compute their specific material gestalt in the process of inflation or deflation. The variability inherent to the related manufacturing and fabrication techniques constitute a vast repertoire of possible morphological manipulations of the pneumatic systems, and thus provide the inroad for strategic environmental modulations. These intricate reciprocal effects between form, force and performance will be explored by the students through series of increasingly refined physical modeling and testing.

Computational Form – Digitally Simulating Pneu Behavior

In feedback with the physical investigations the students will conduct digital experiments in order to rapidly generate design variations based on a custom-written simulation tool, which itself can be further developed and tailored to the group’s specific needs during the workshop. This enables not only to digitally explore the forming behavior of pneumatic systems and to investigate related performance tendencies, but also to derive fabrication data for manufacturing.

Unfolding Performance Capacity – Physically Monitoring Environmental Behavior

One critical facet in the students’ development work from generic systems towards specific prototypes will be the understanding and unfolding of the system’s environmental performance capacity. The adaptive nature of pneus should be utilized to respond to the climatic conditions of Southern California. The physical models’ interaction with the surrounding environment and the related modulation of environmental conditions through this interaction will be observed and monitored through real-world measurements. This will drive the development process and ultimately demonstrate the prototypes’ performance.