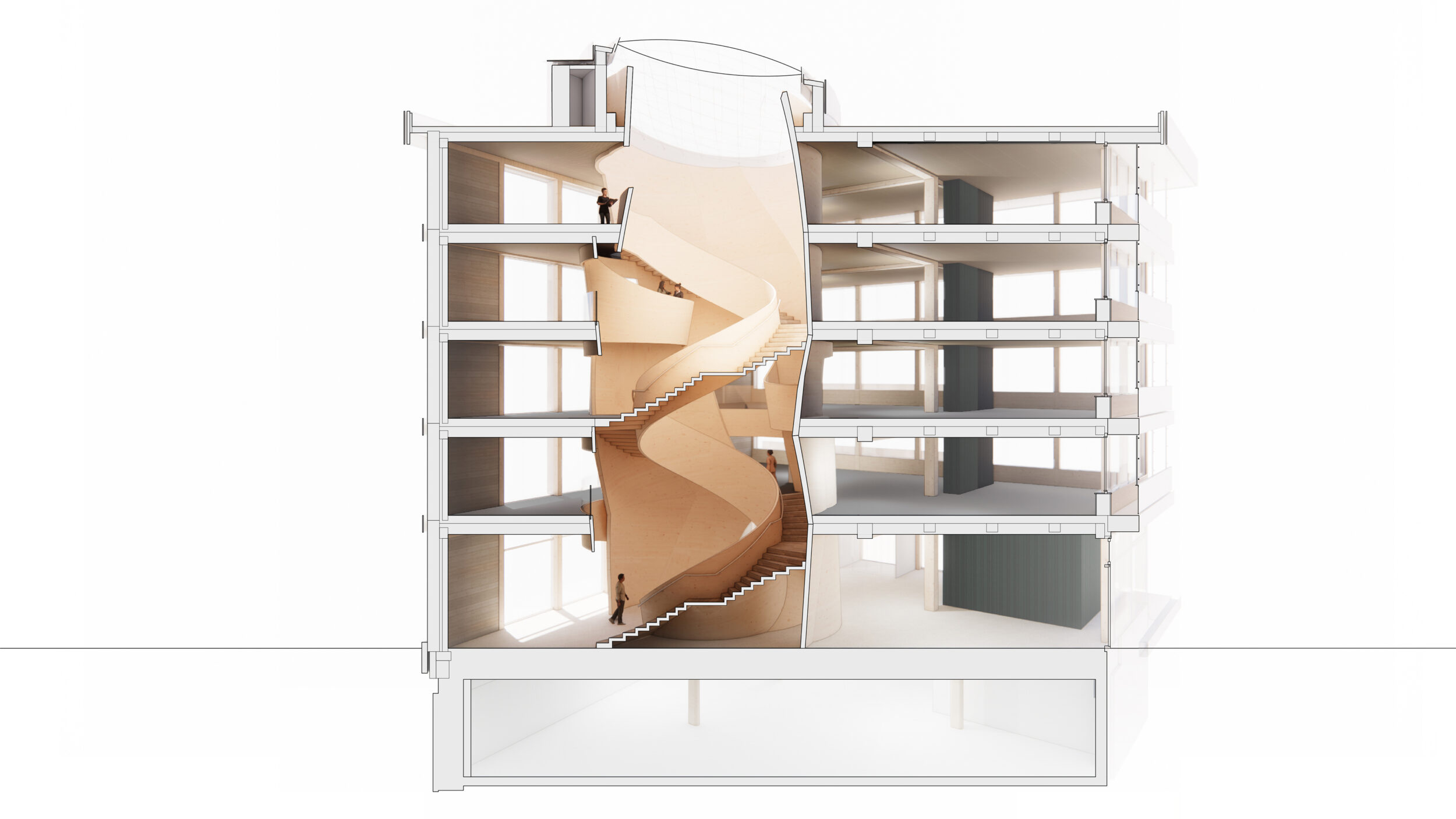

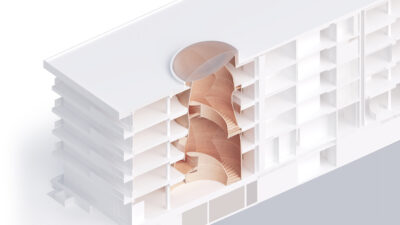

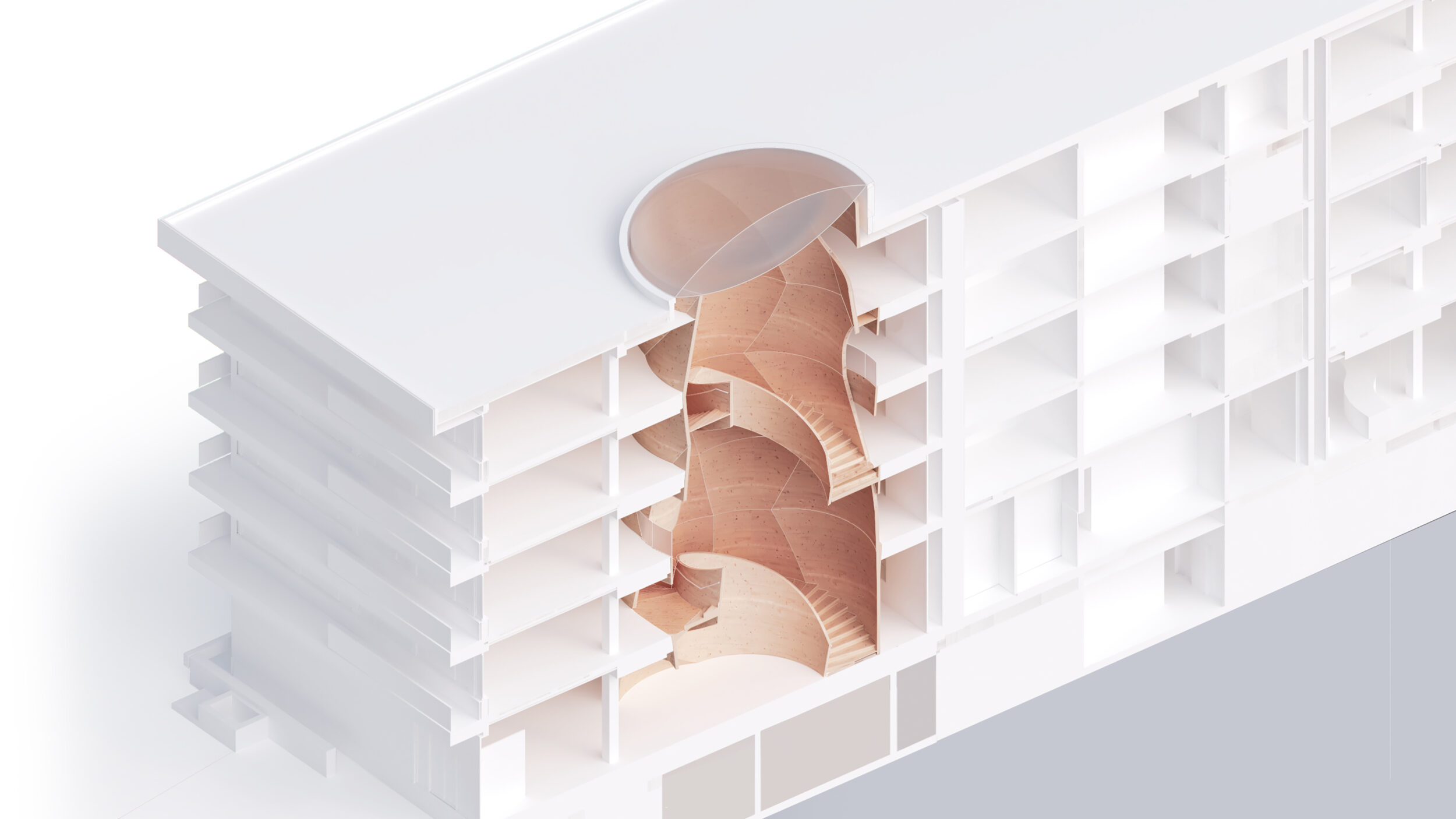

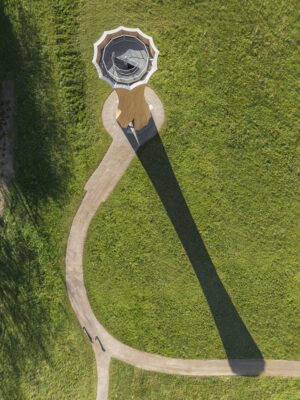

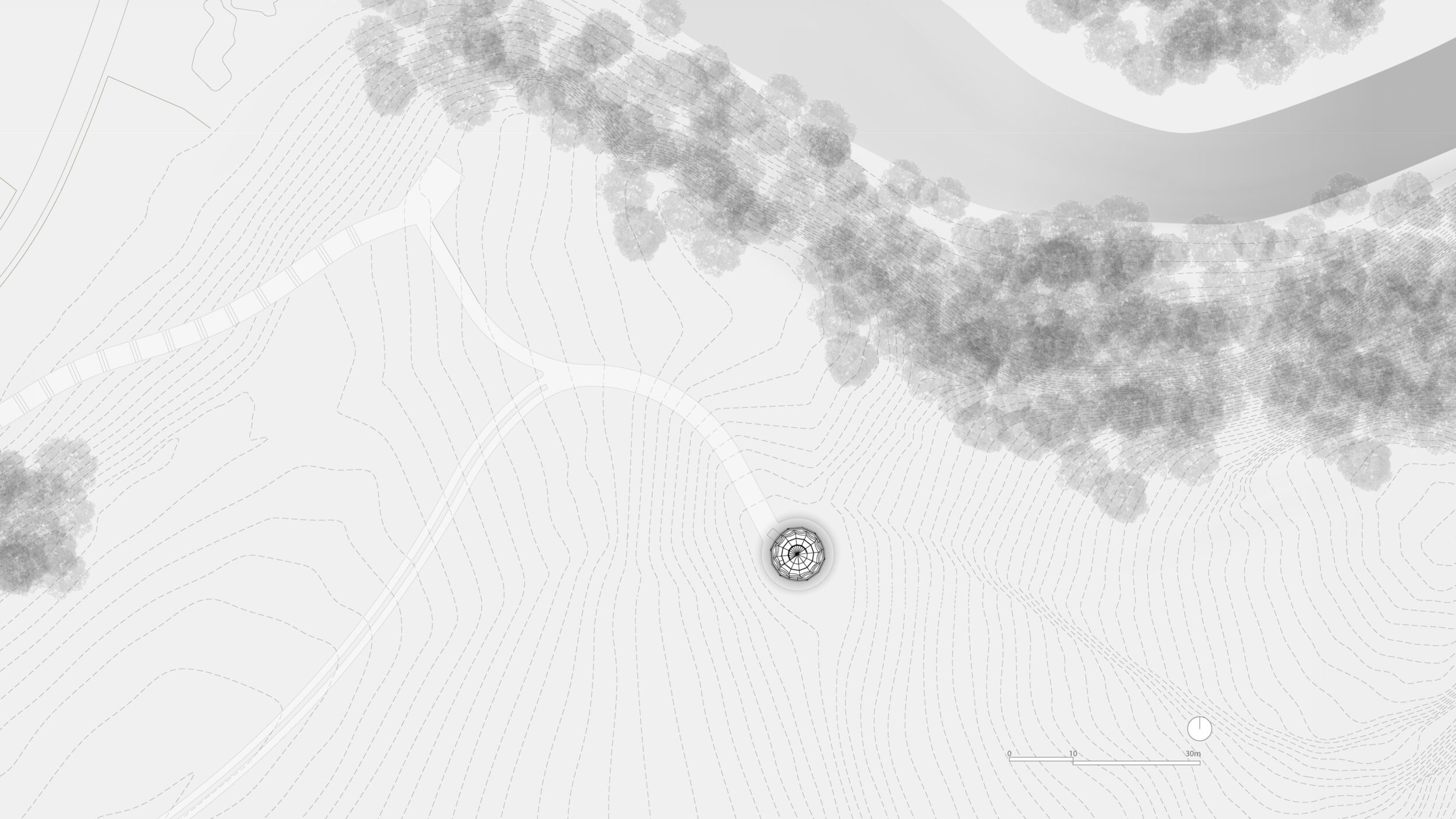

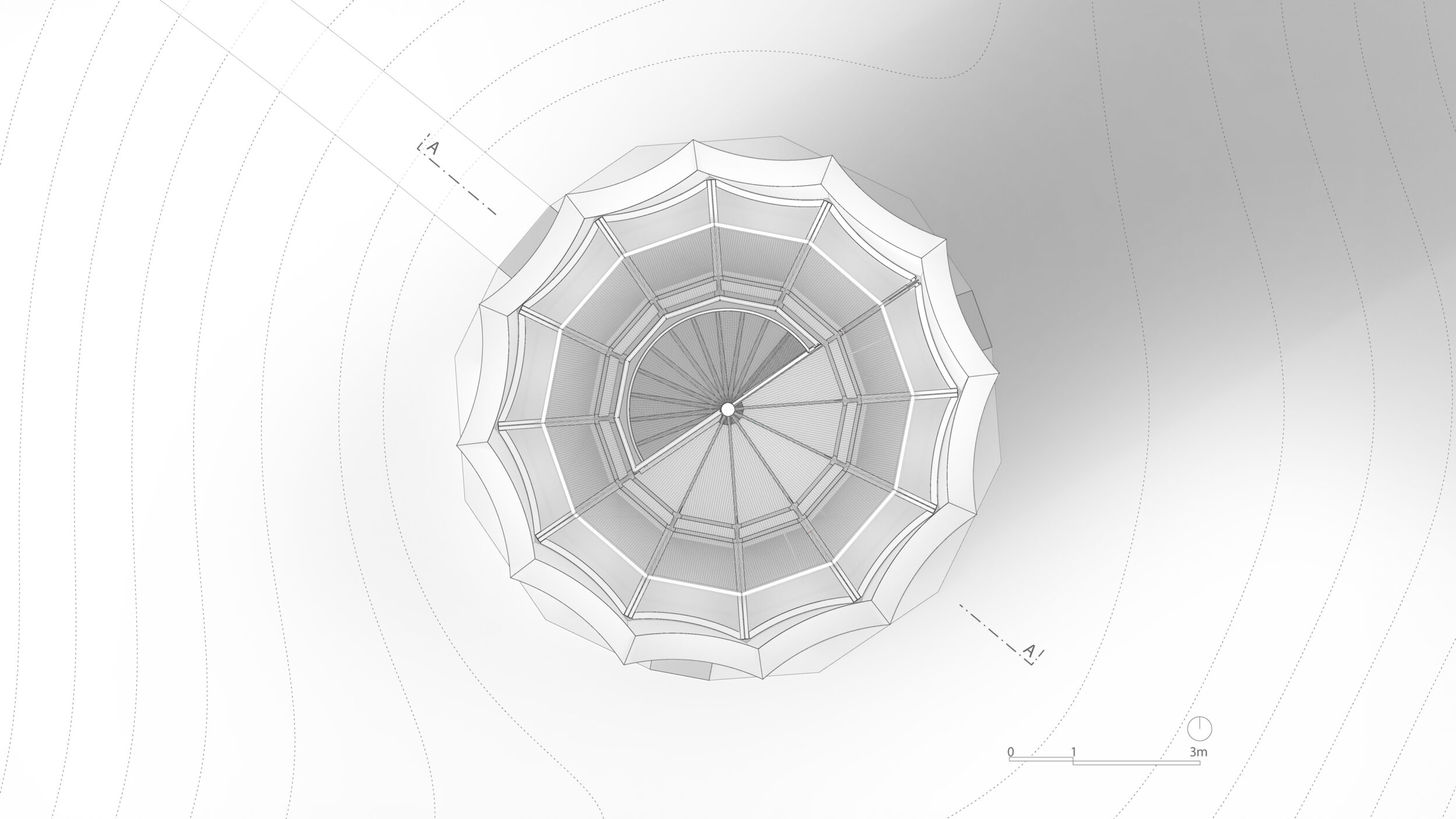

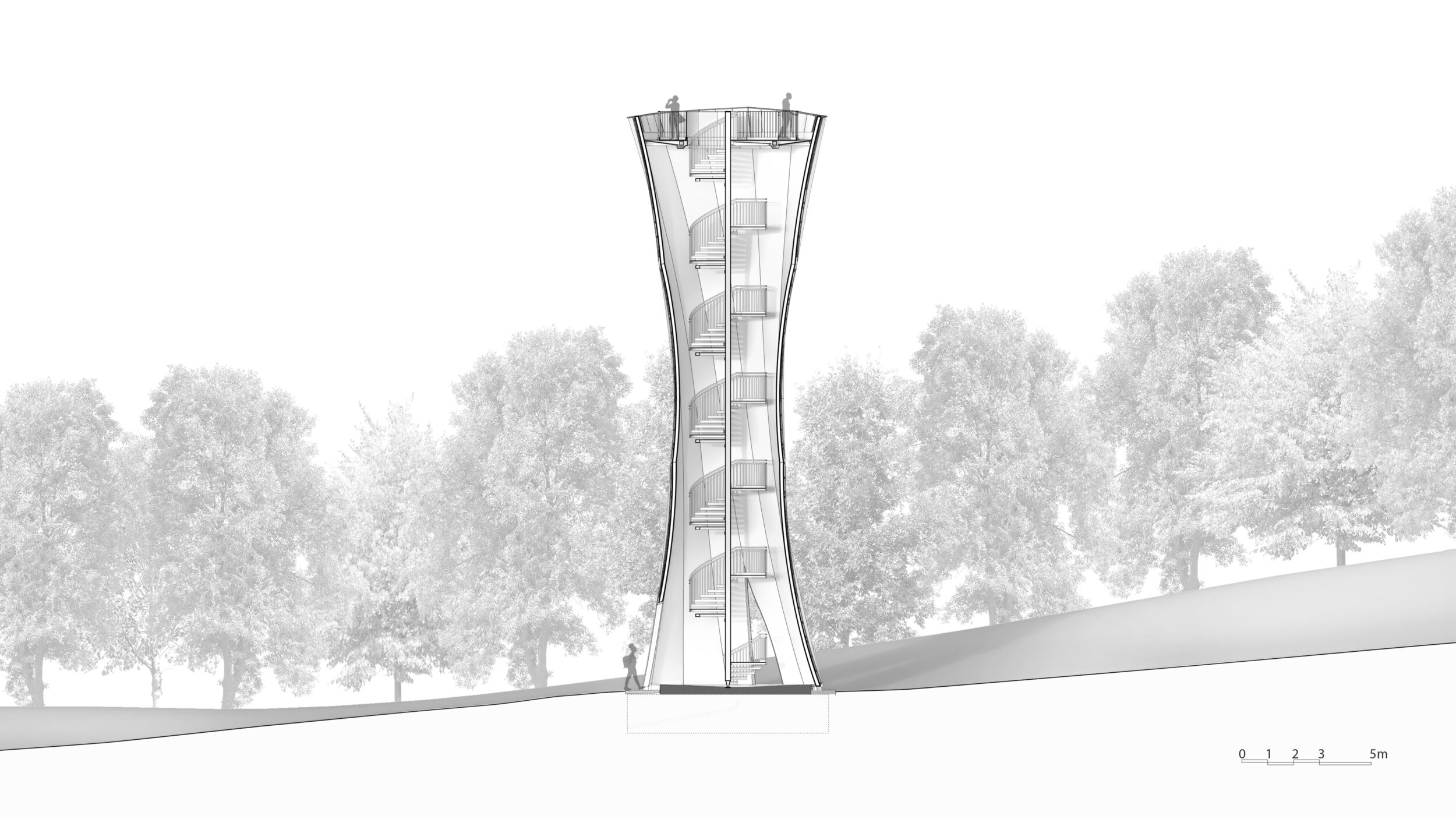

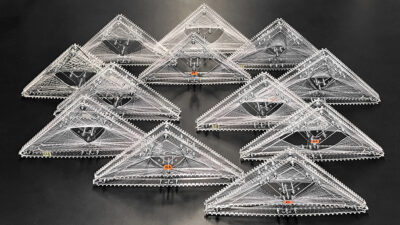

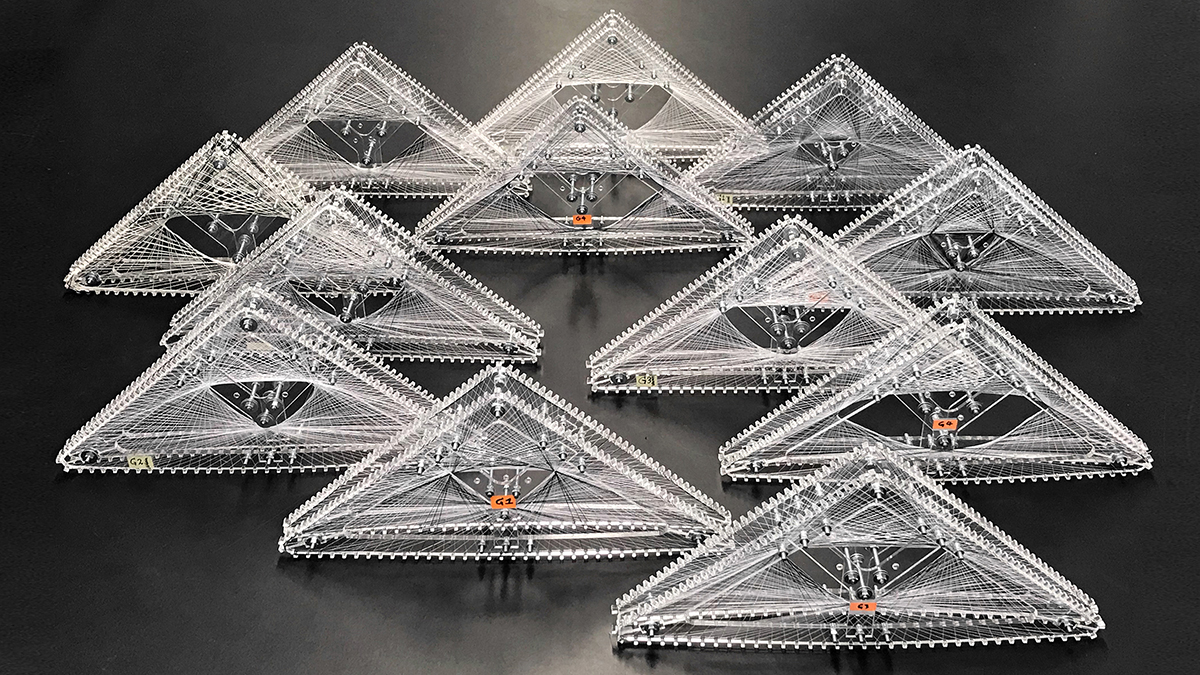

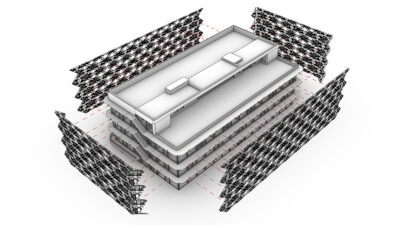

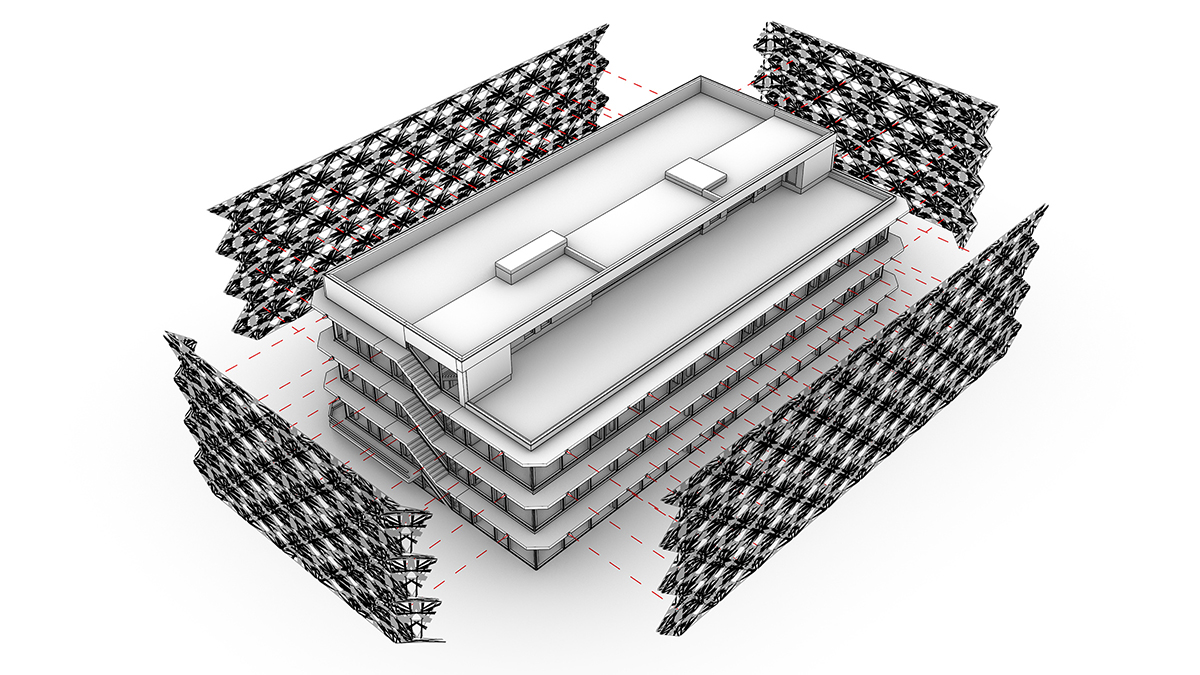

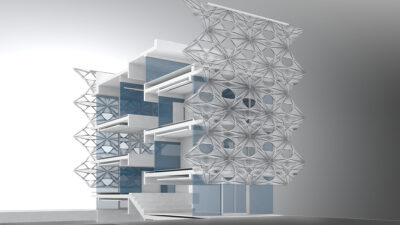

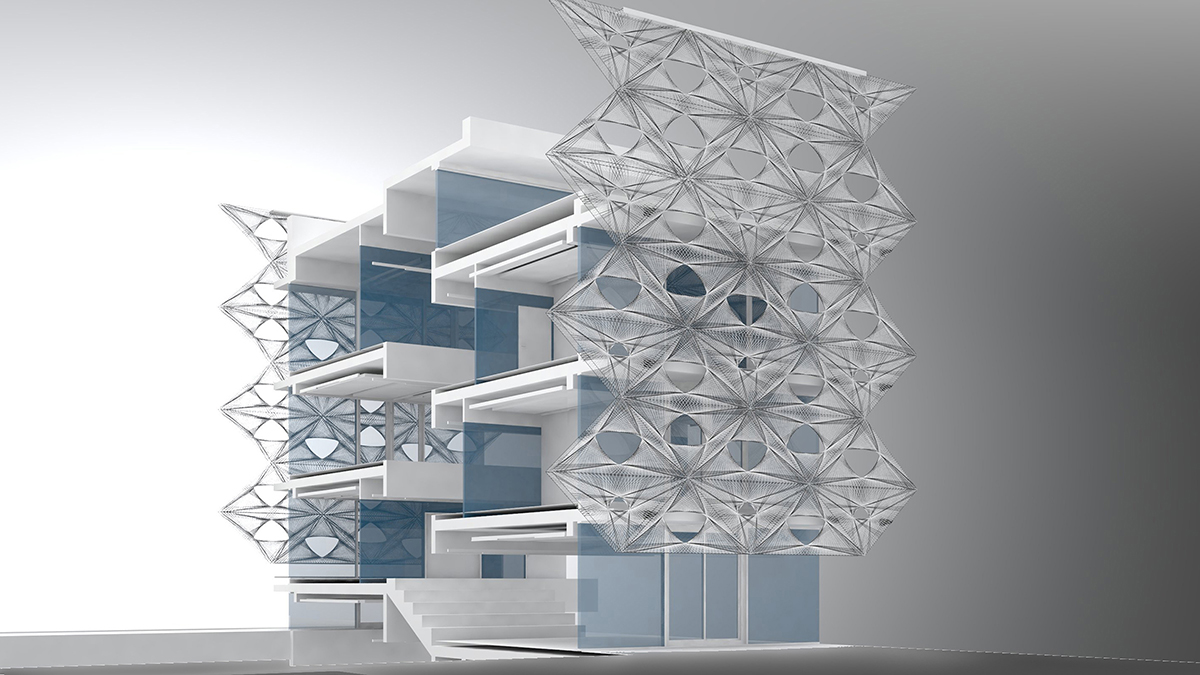

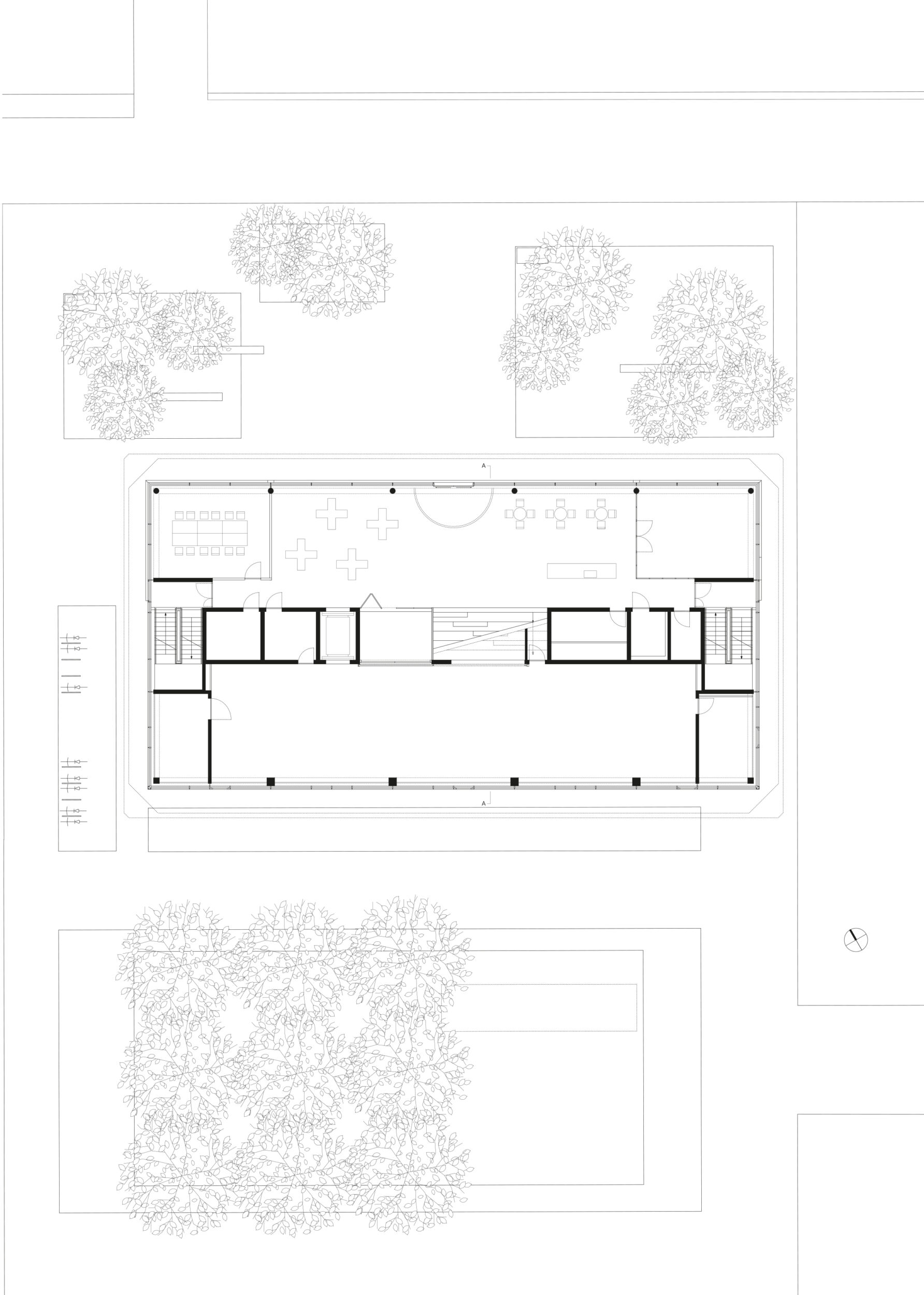

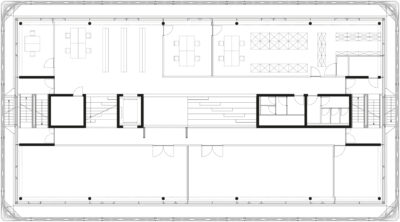

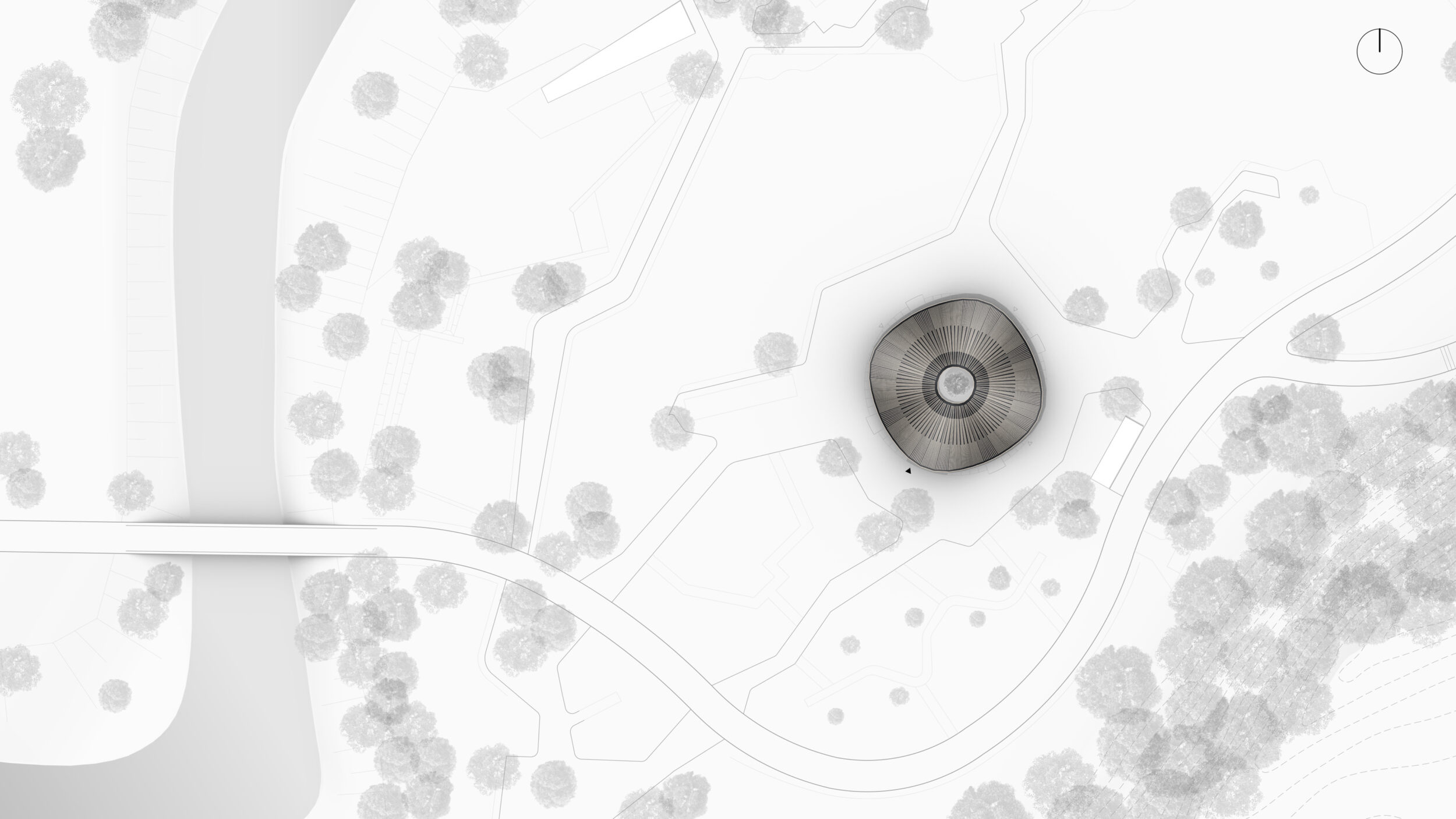

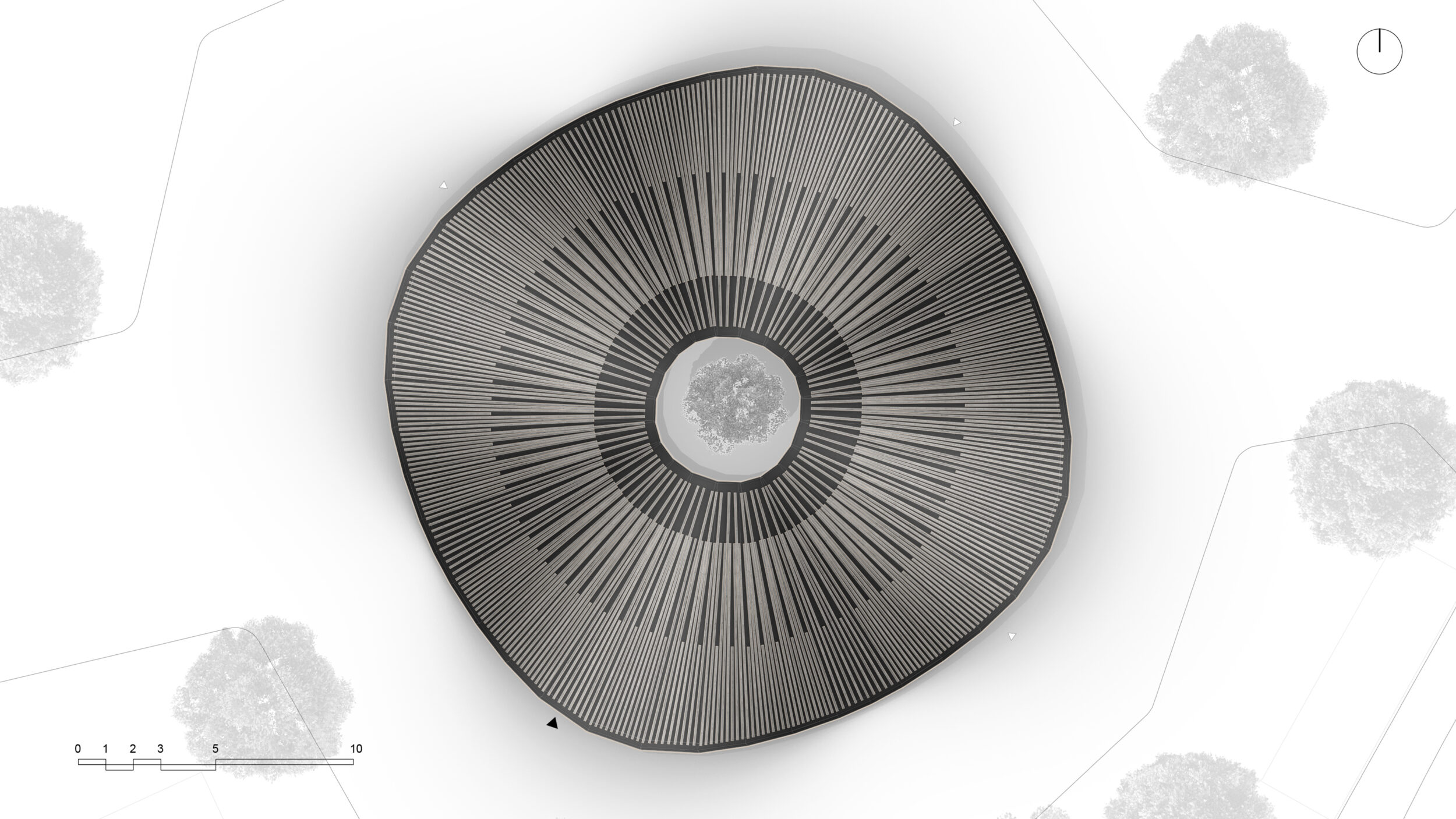

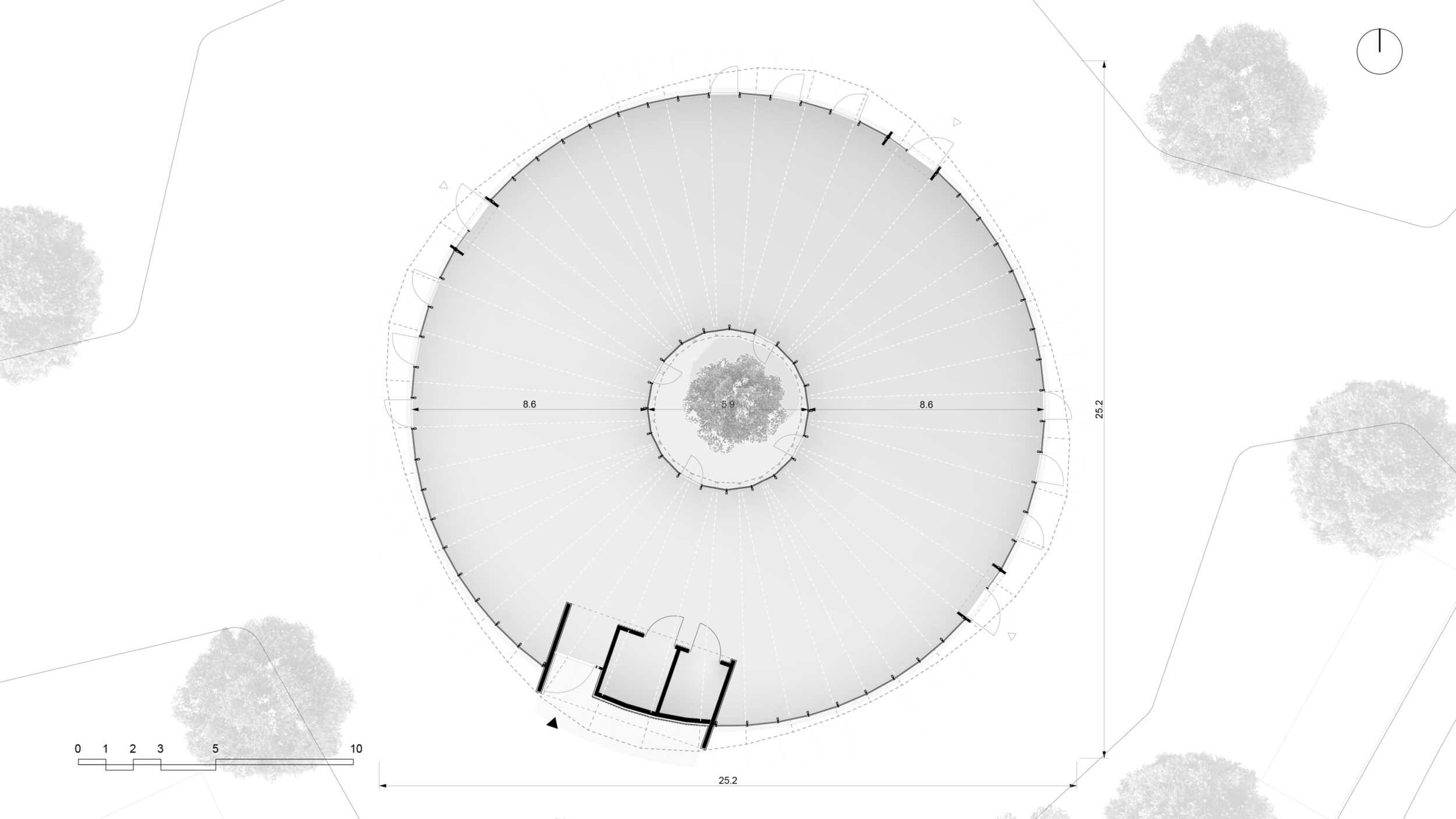

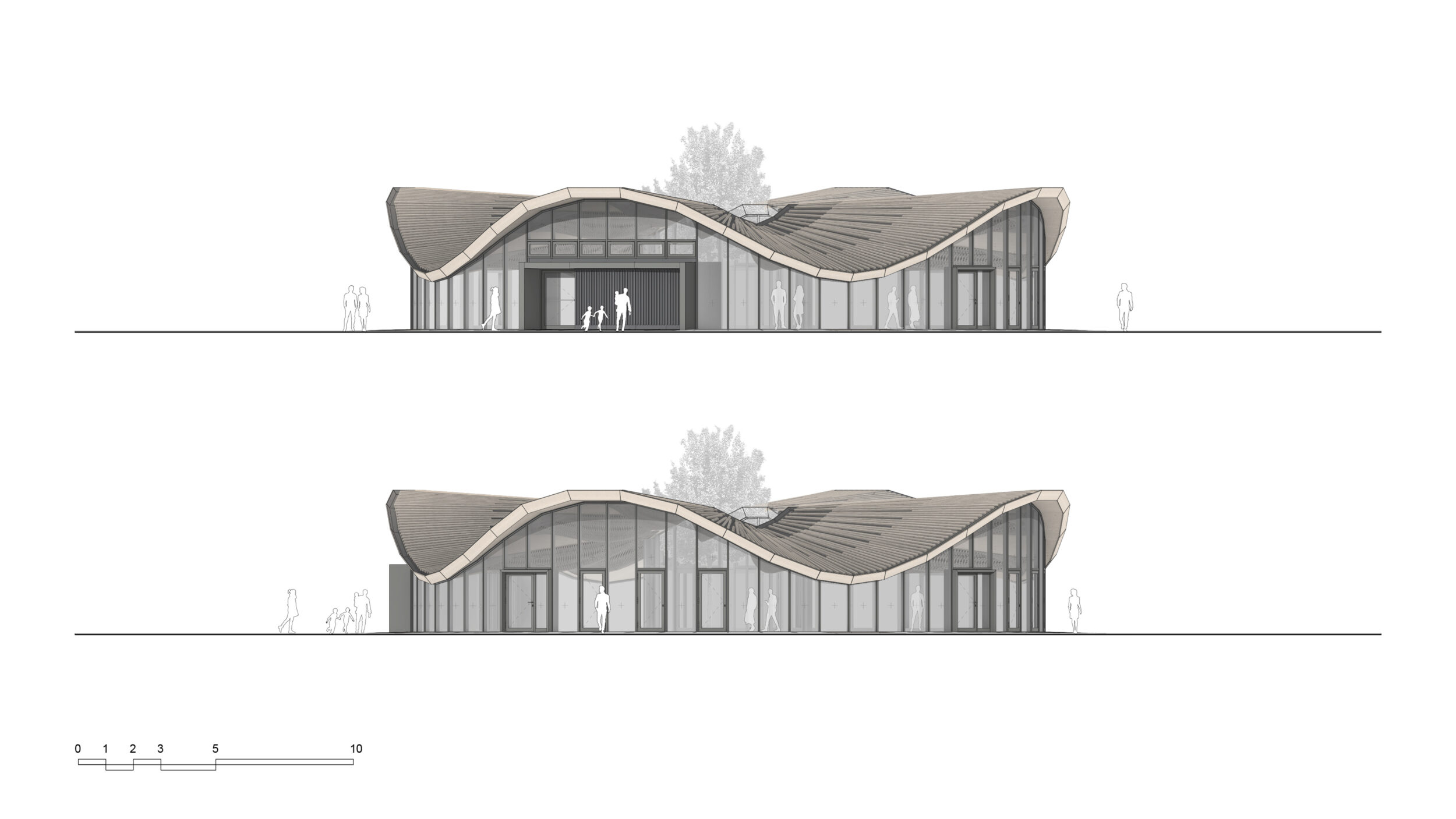

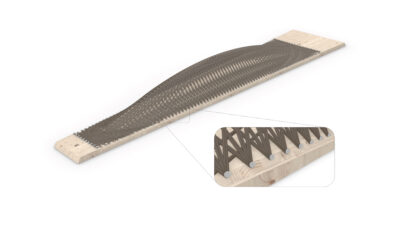

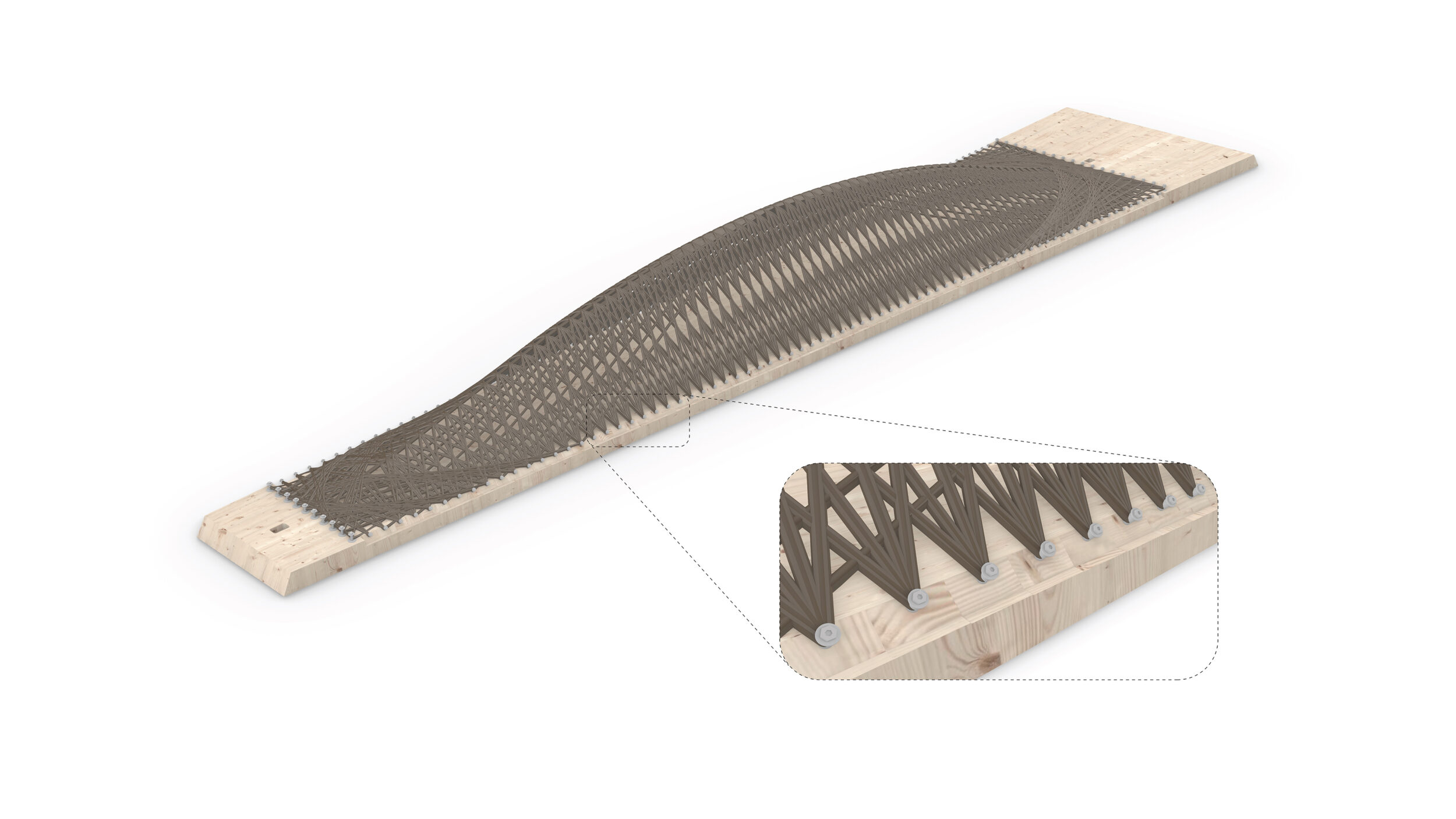

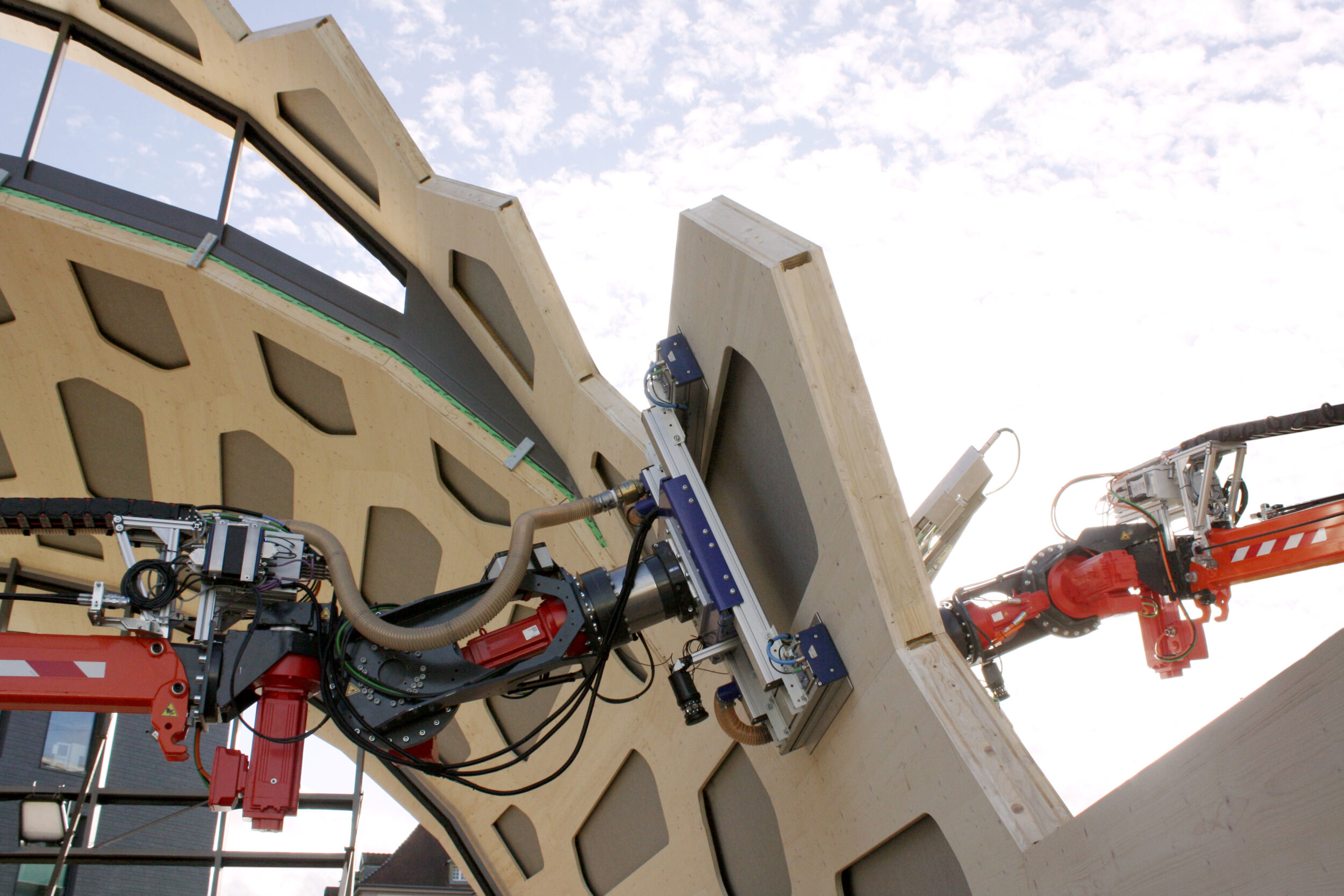

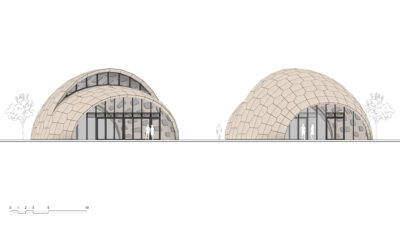

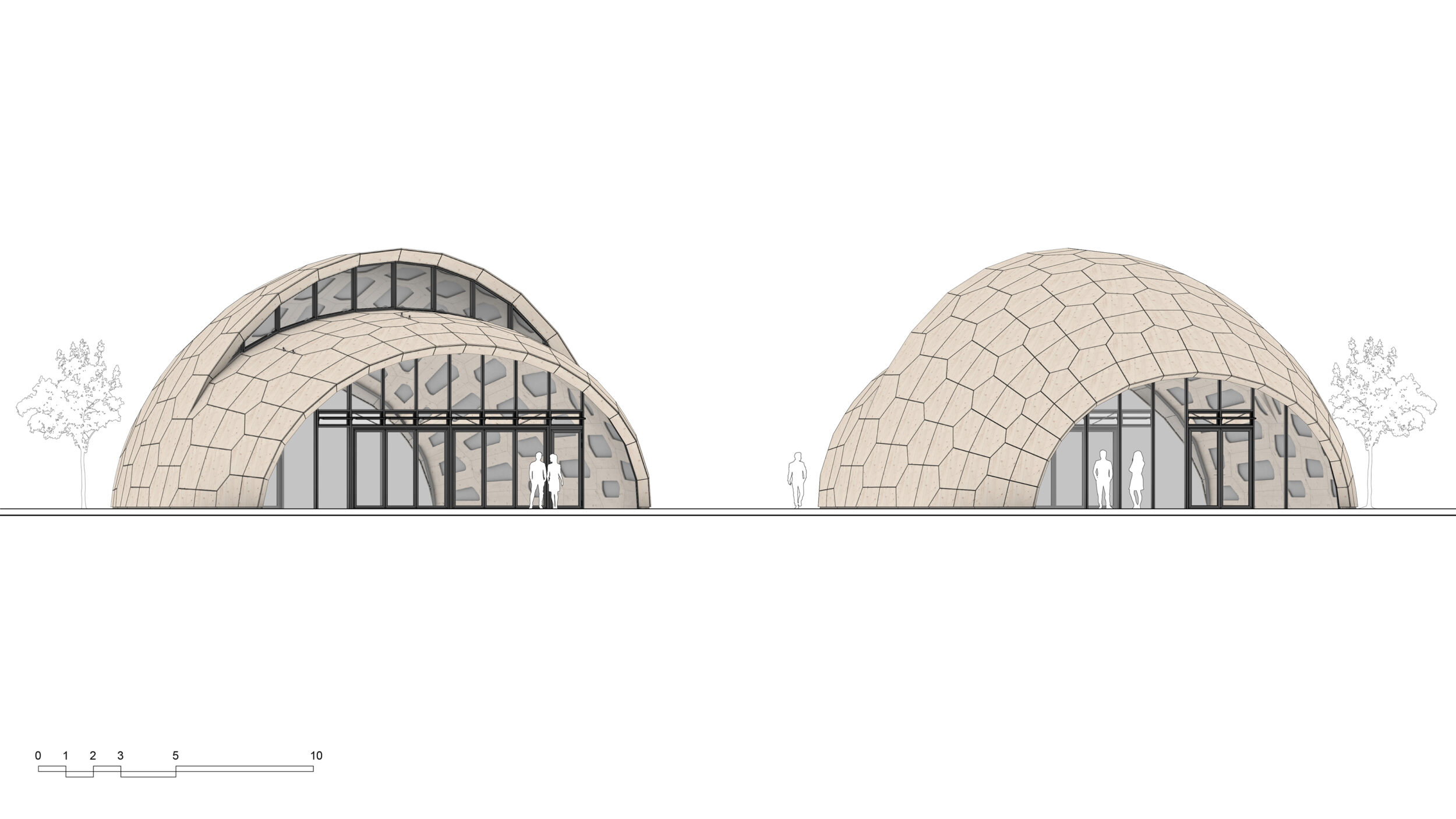

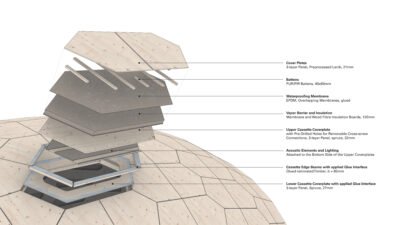

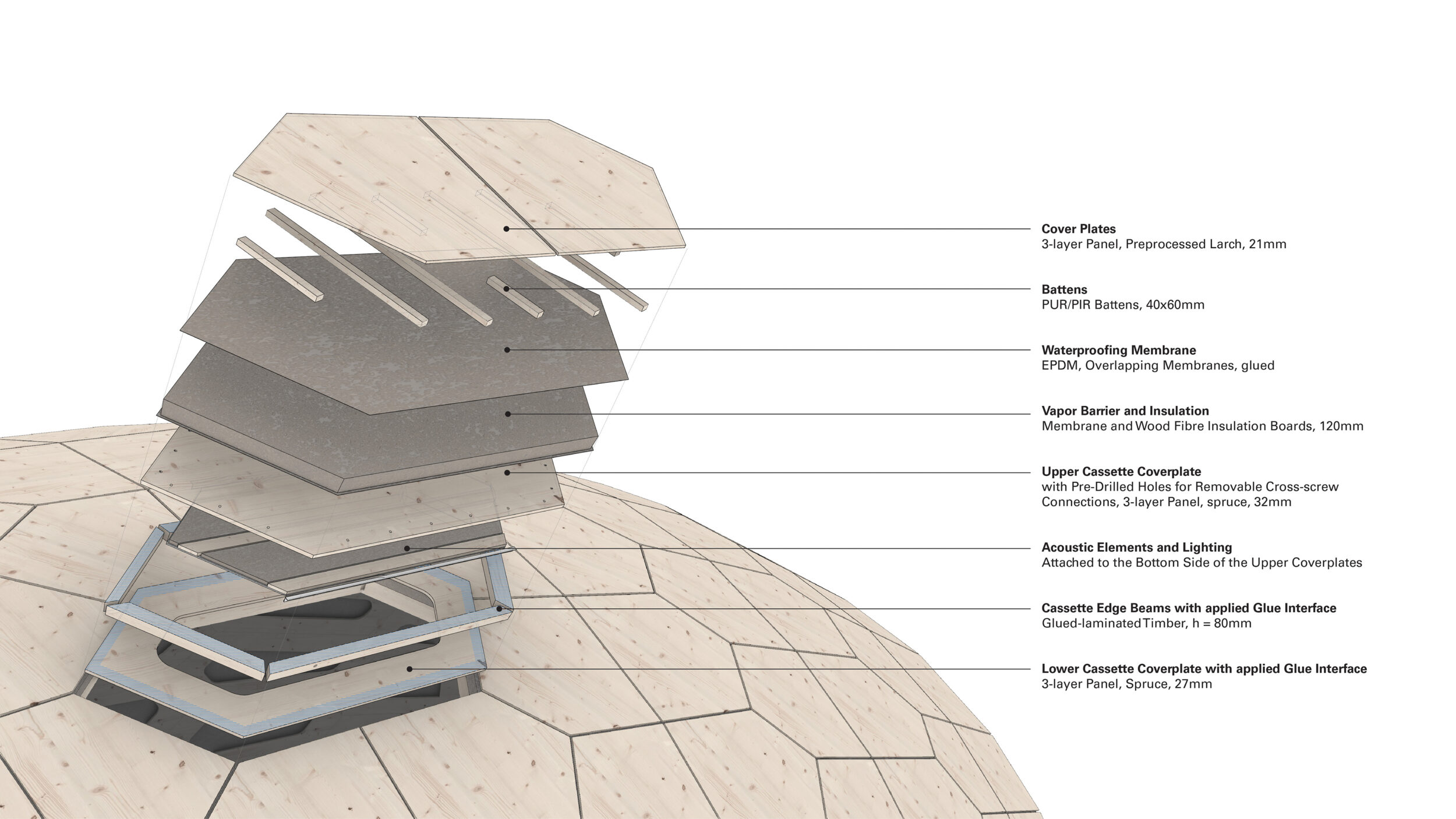

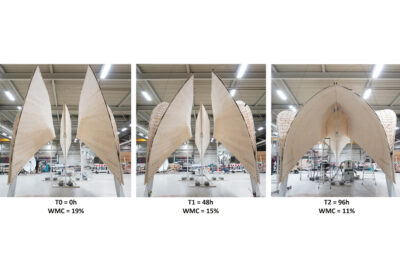

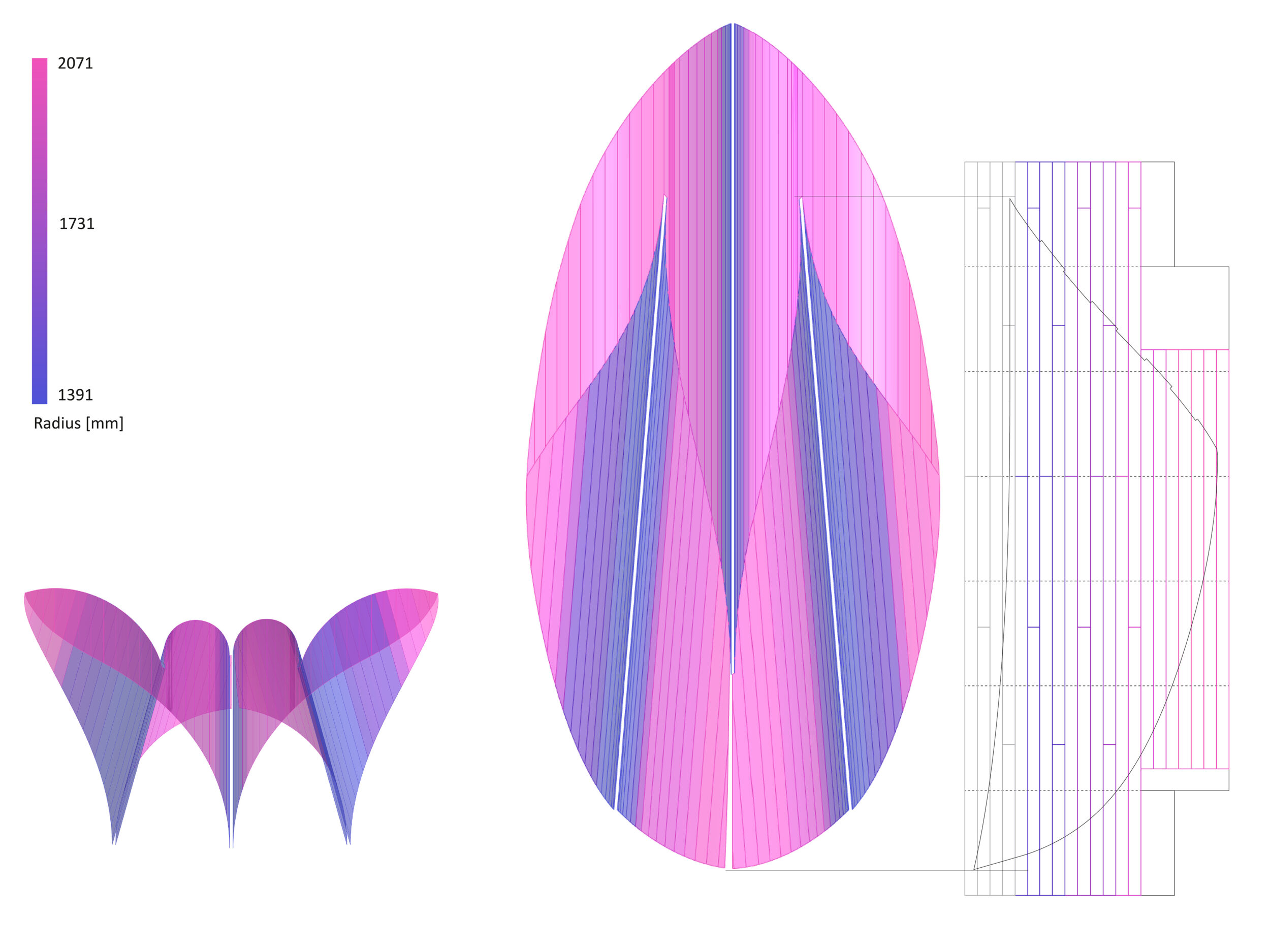

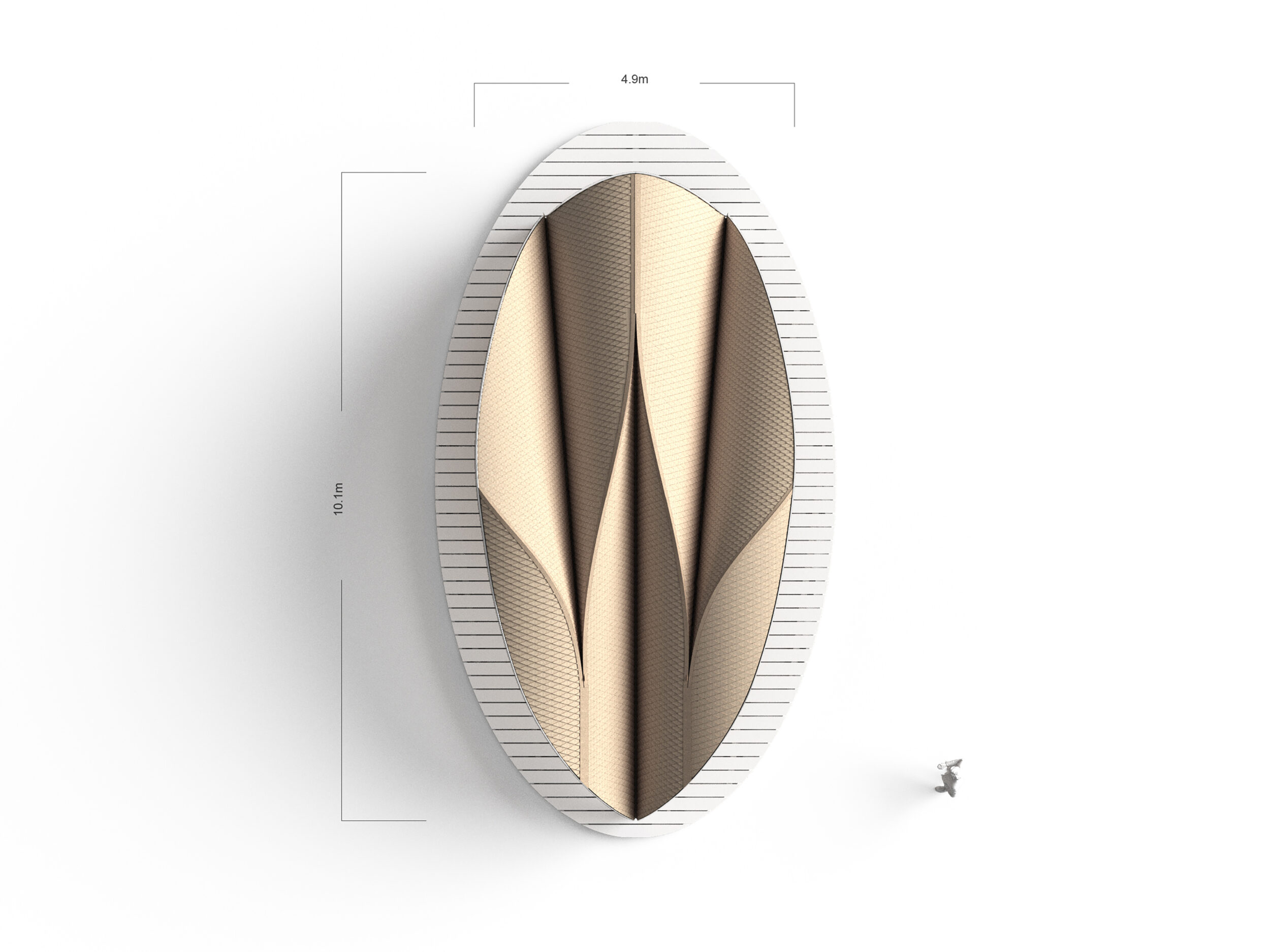

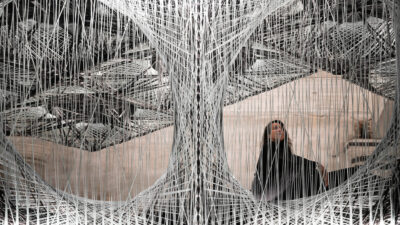

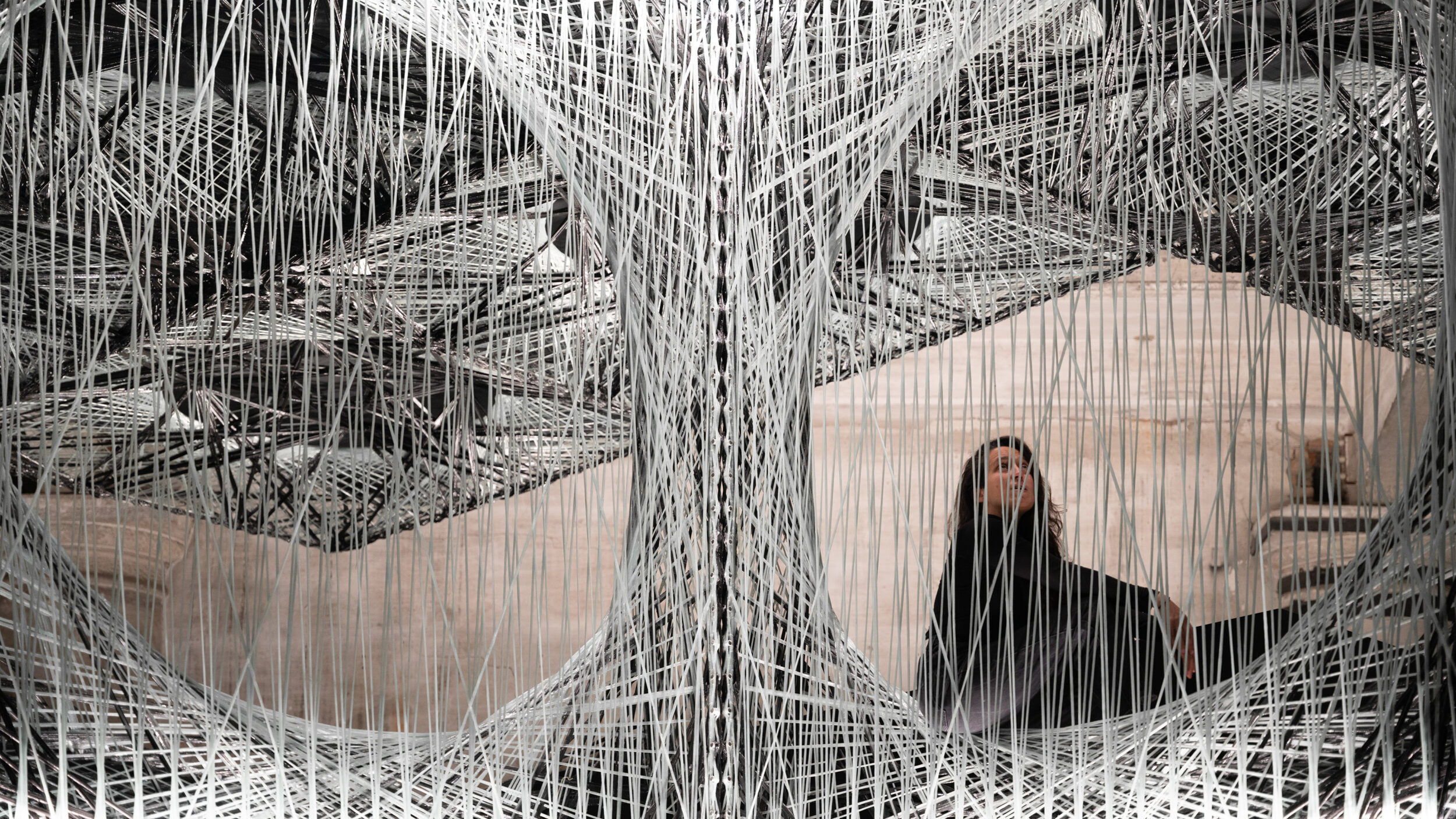

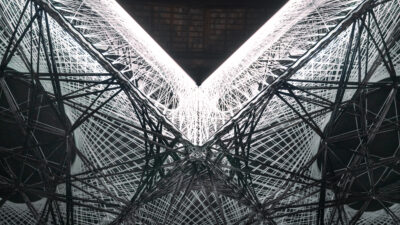

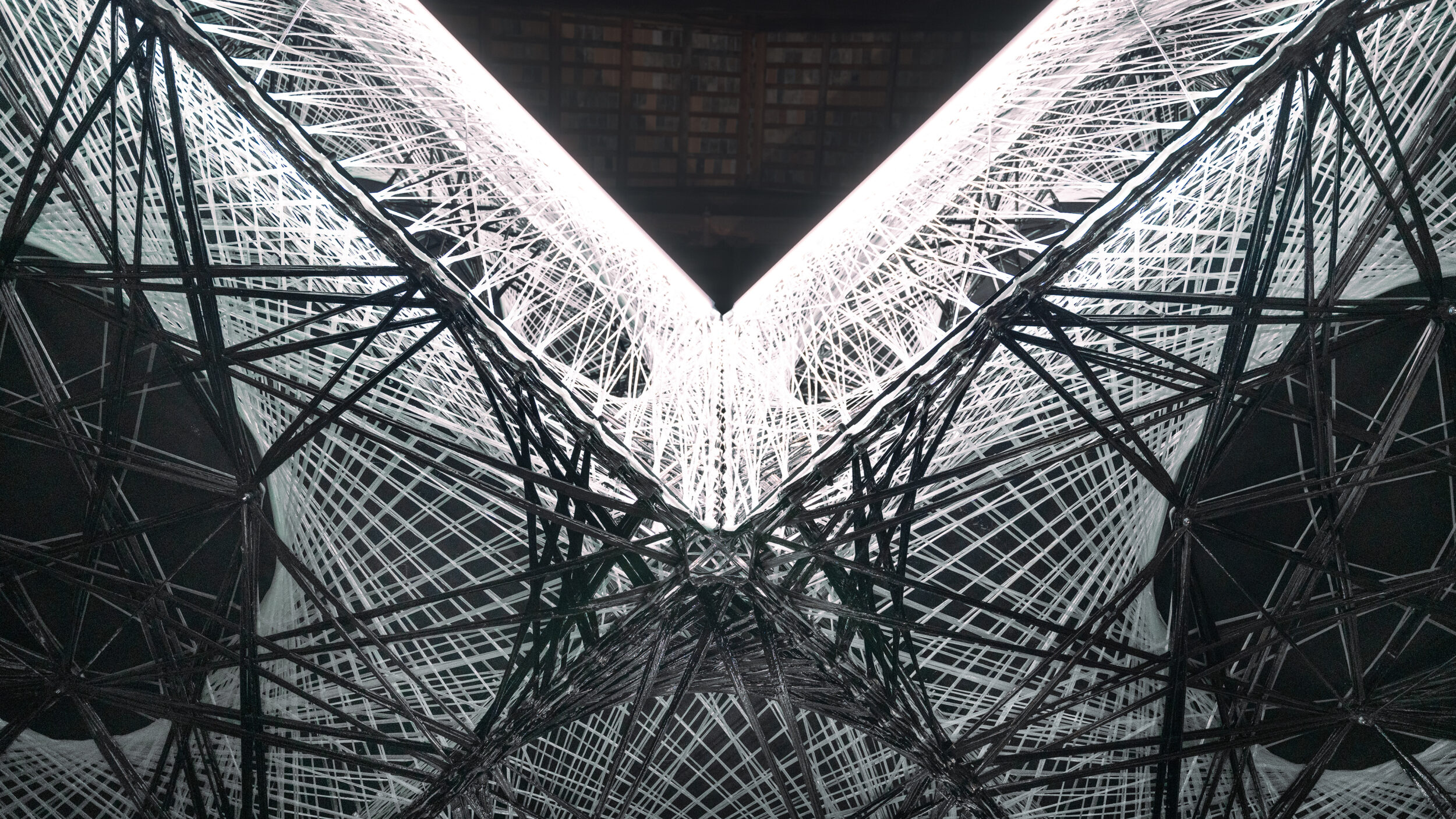

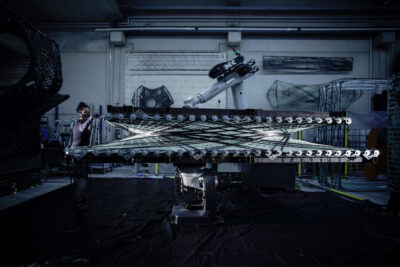

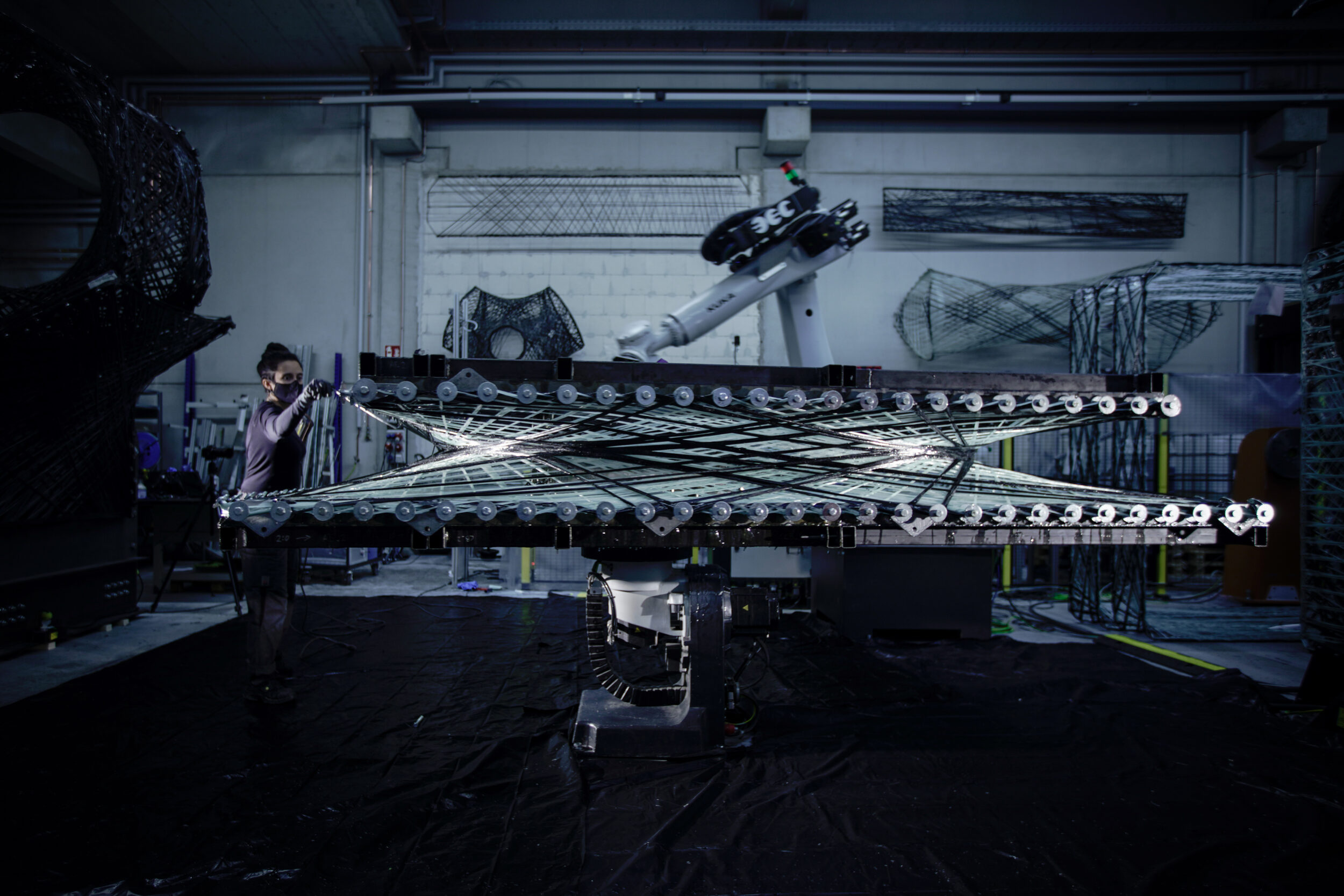

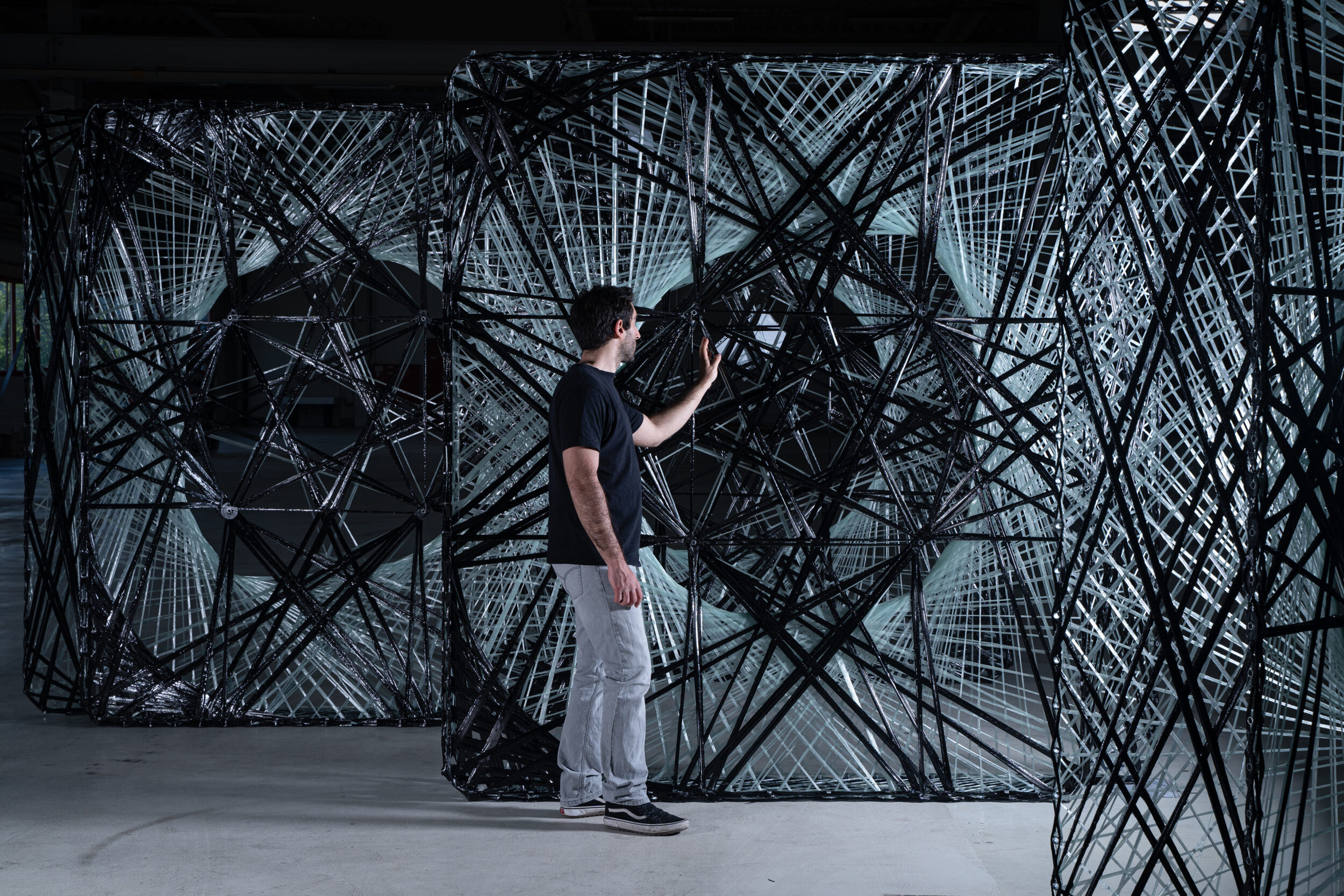

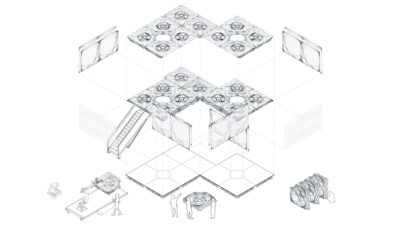

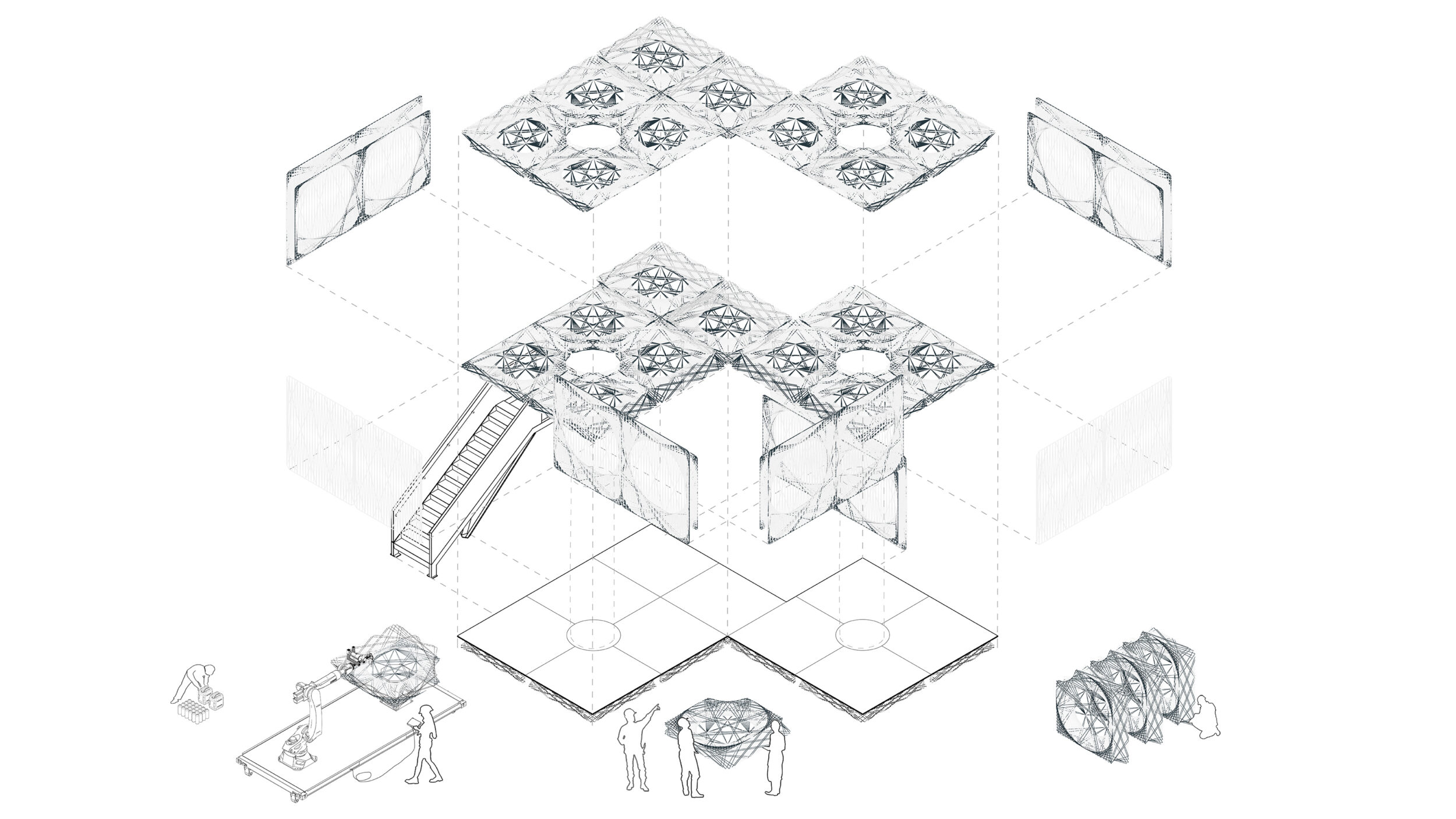

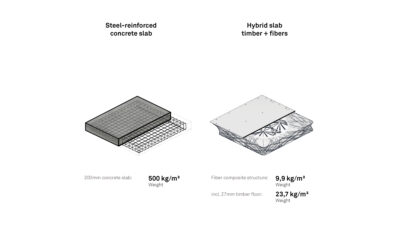

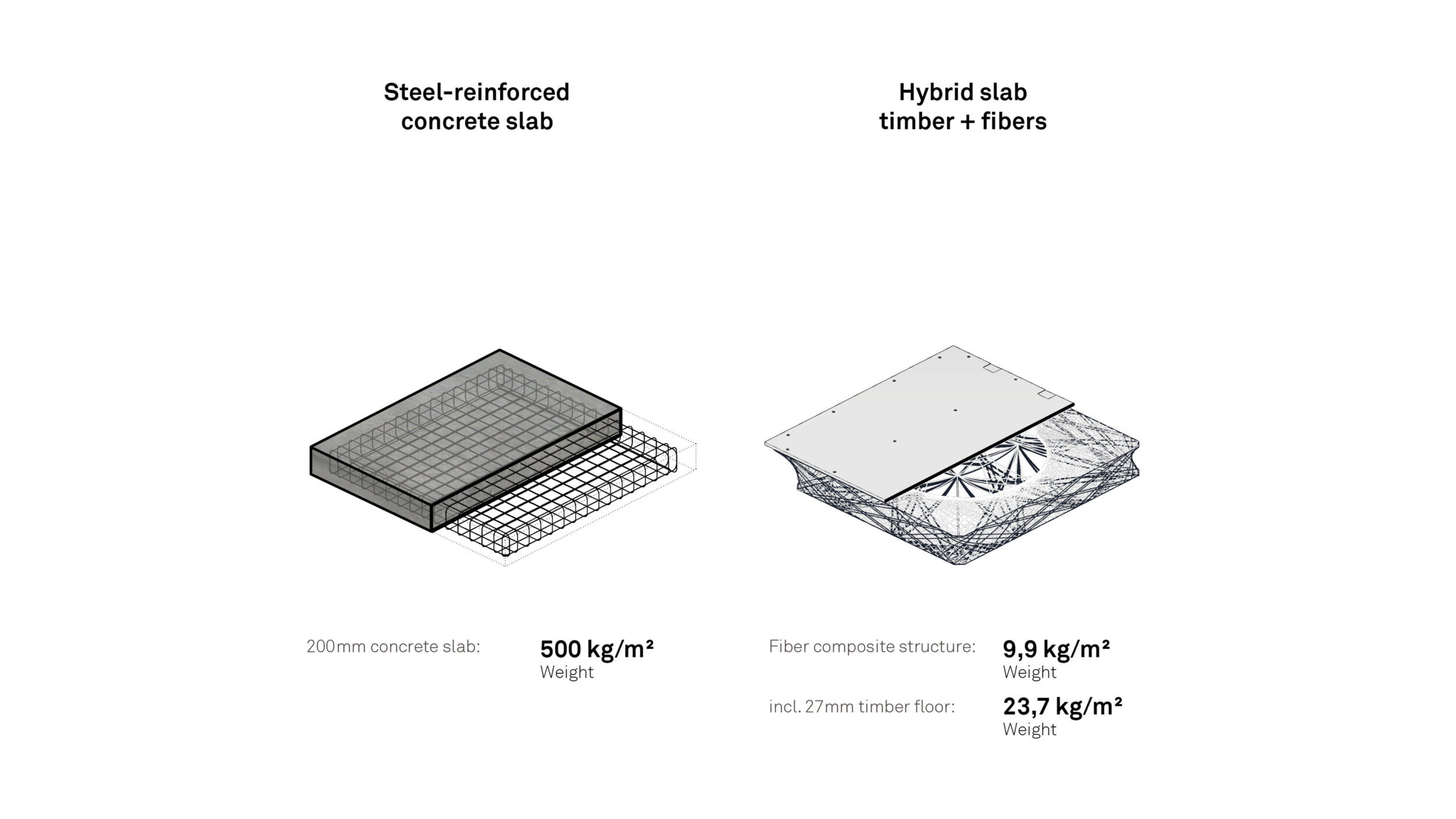

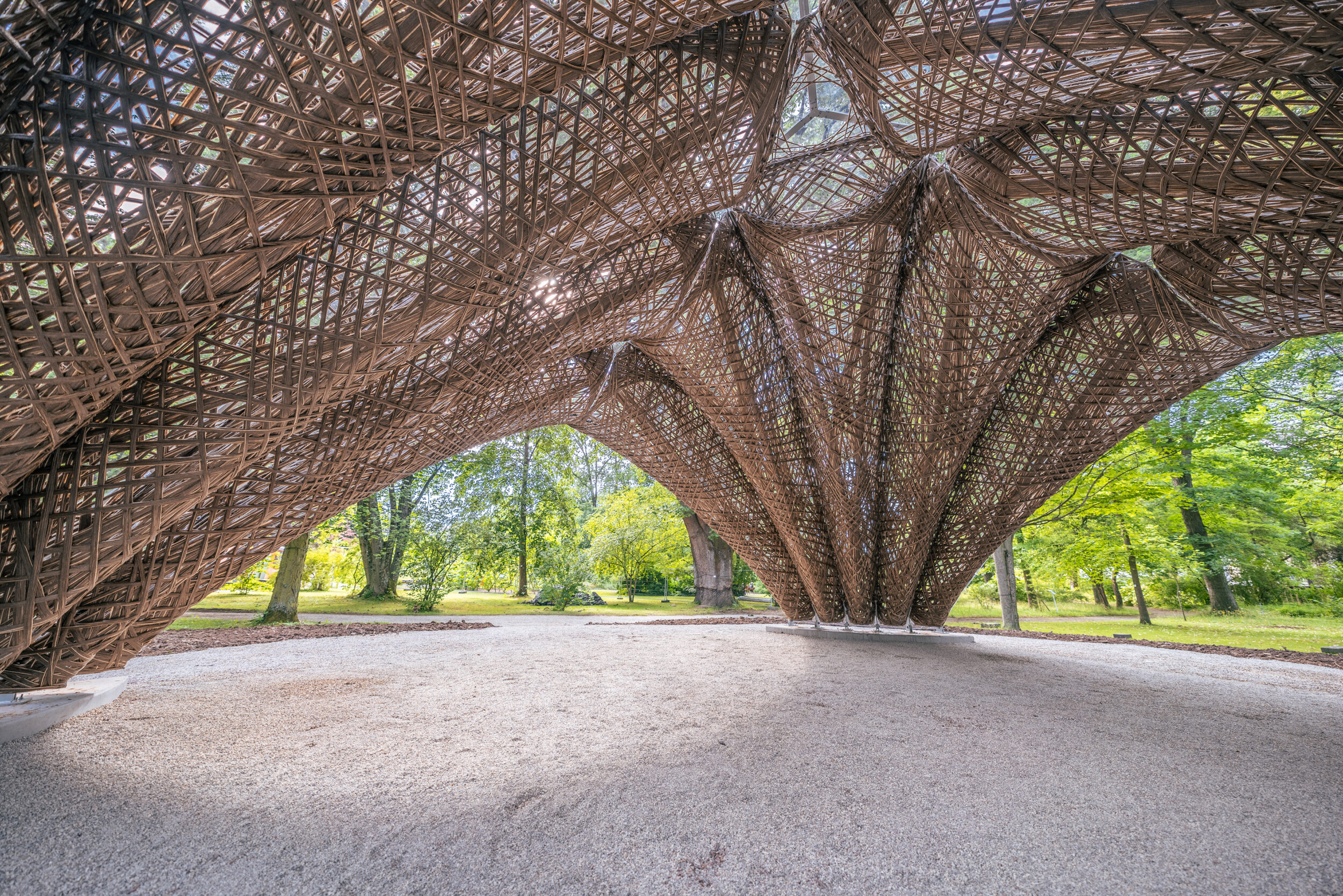

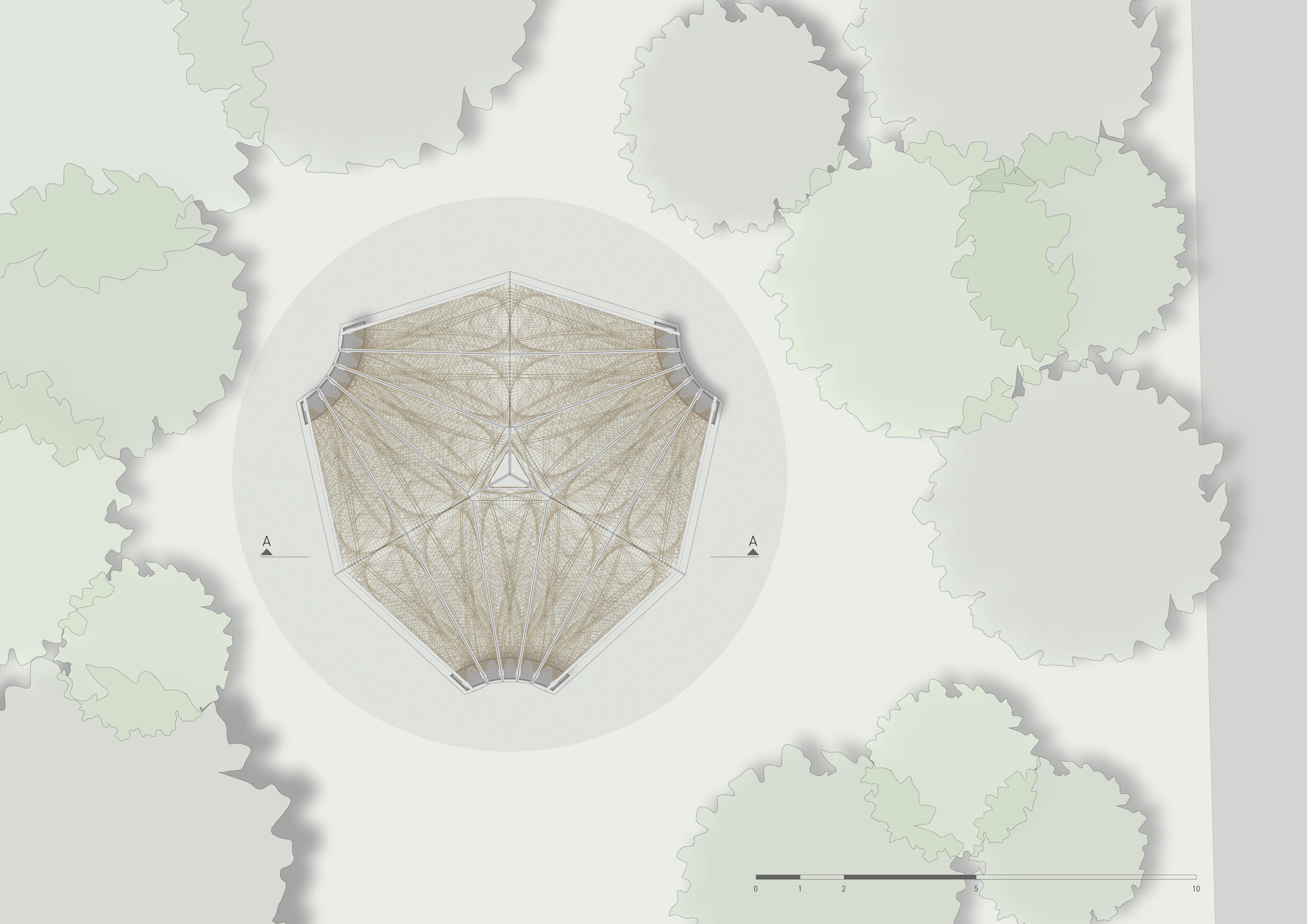

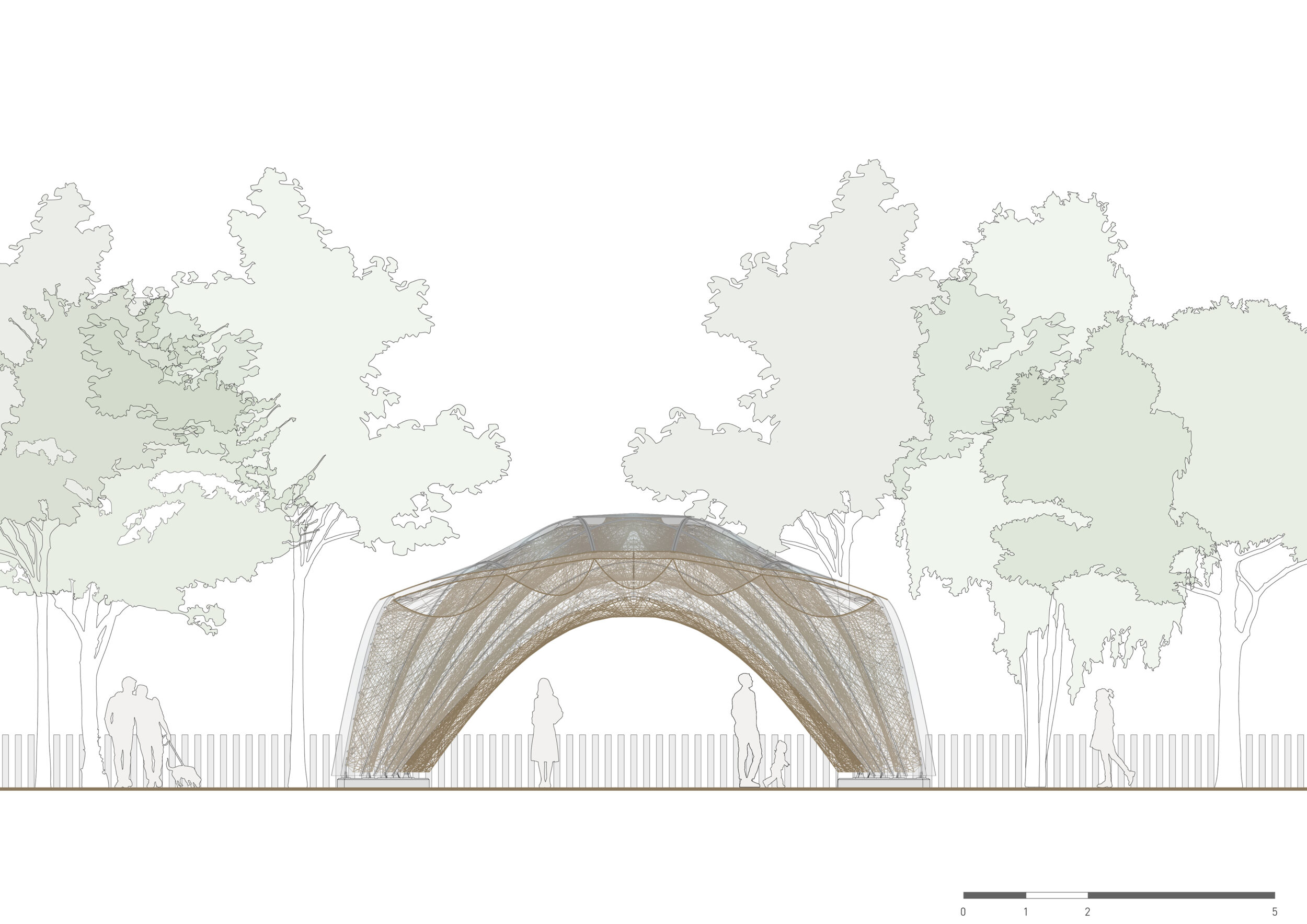

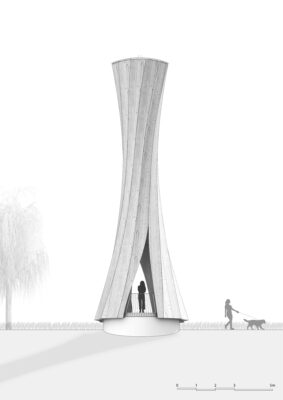

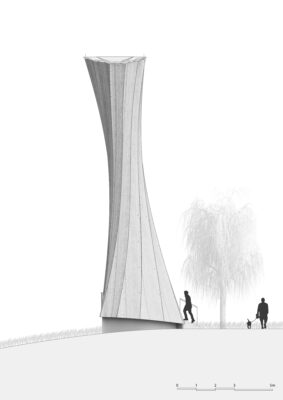

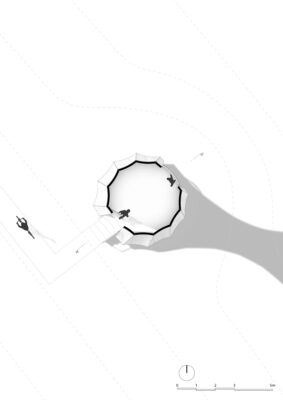

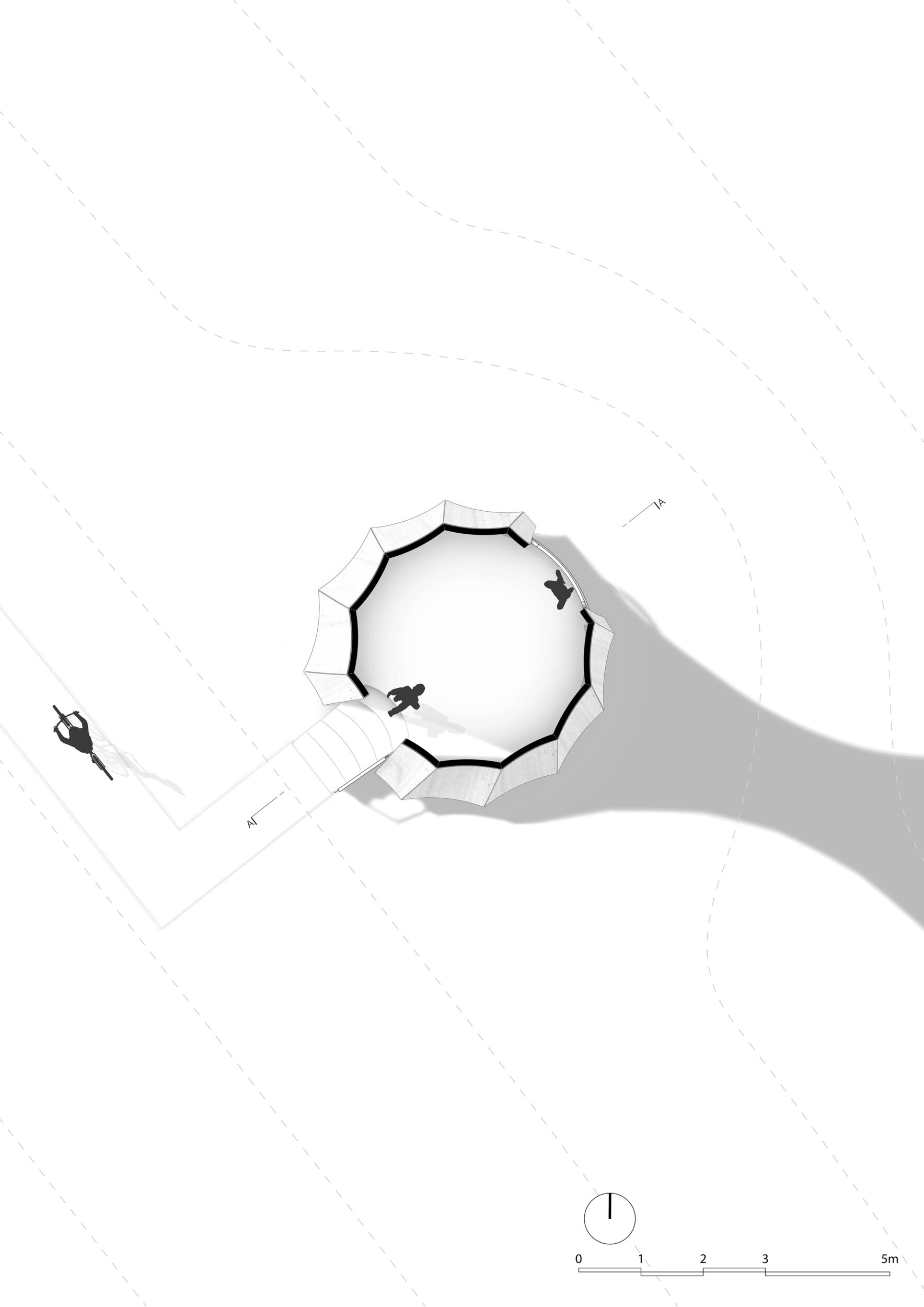

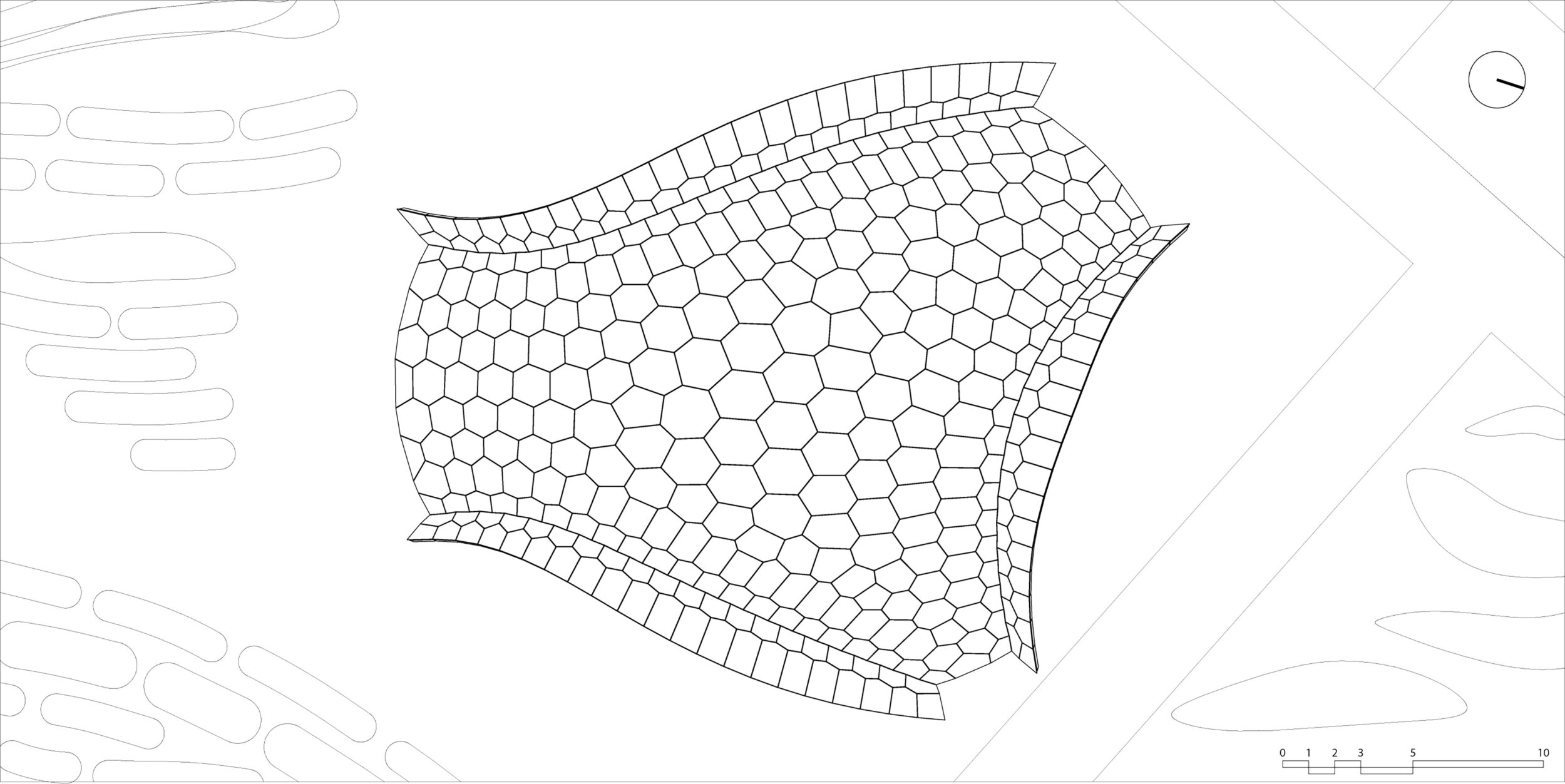

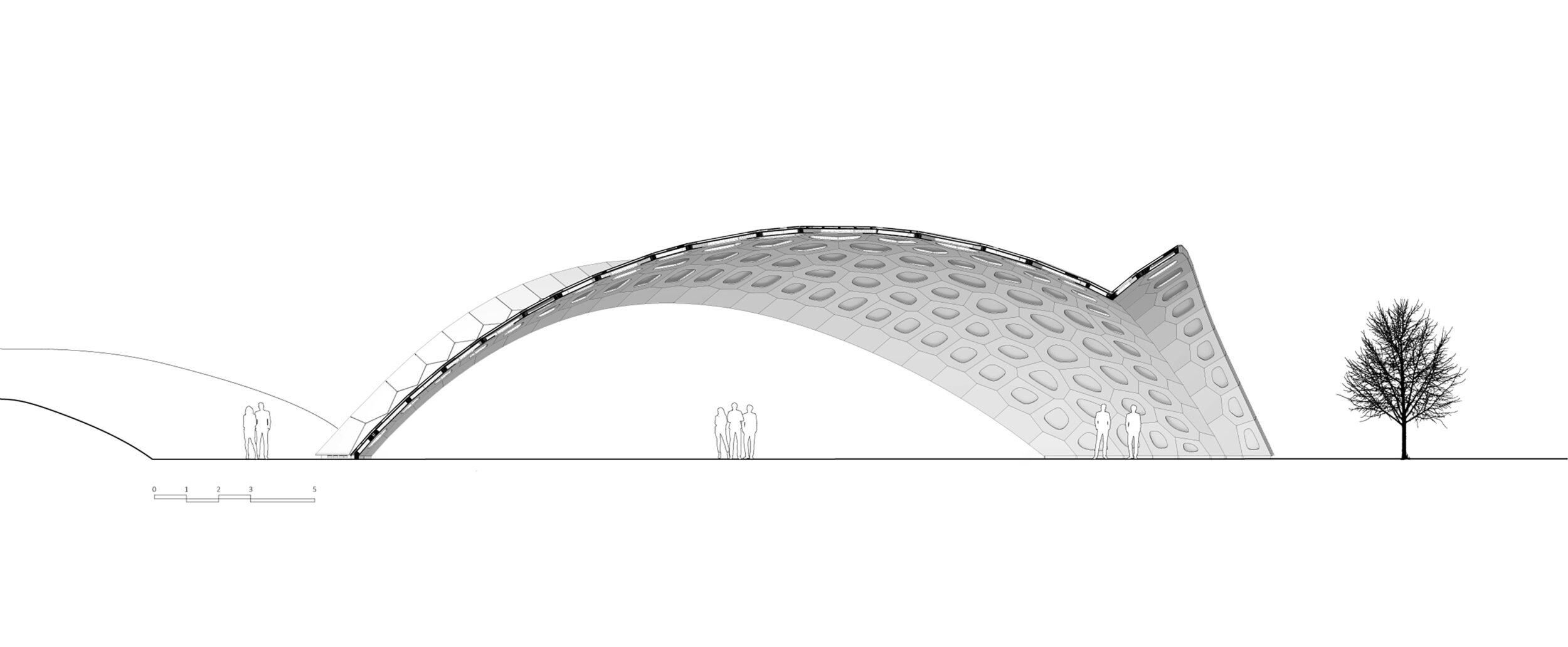

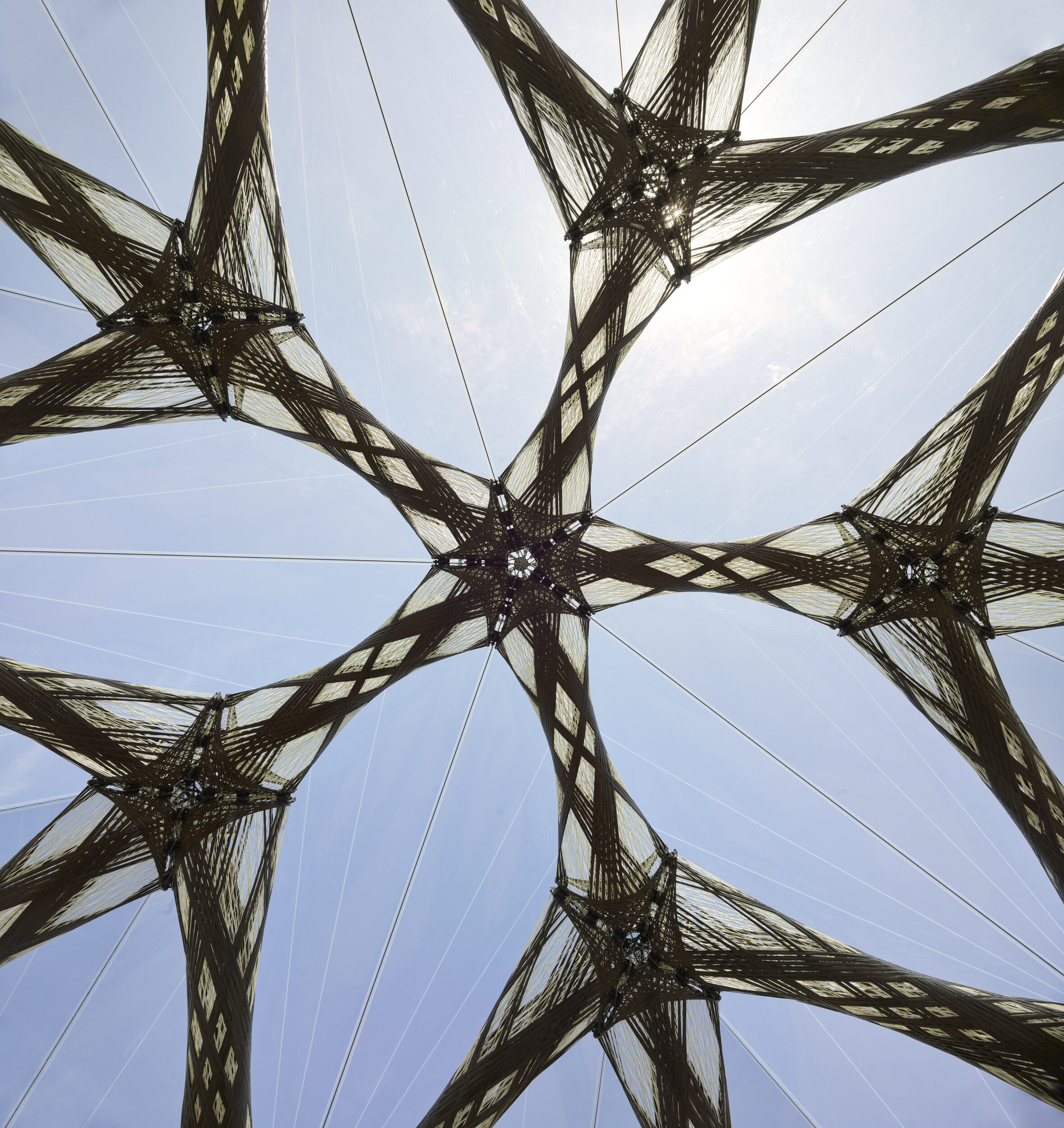

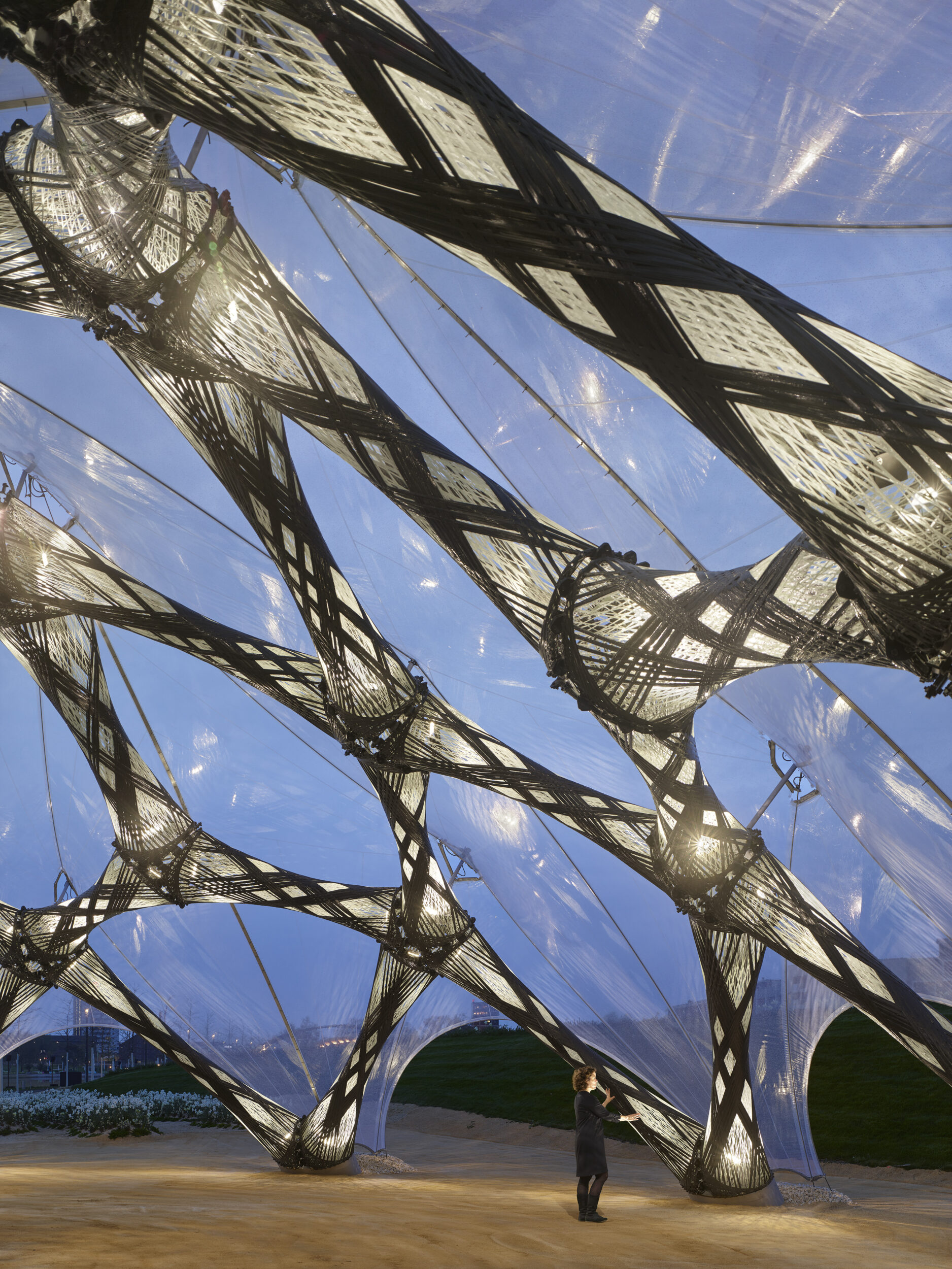

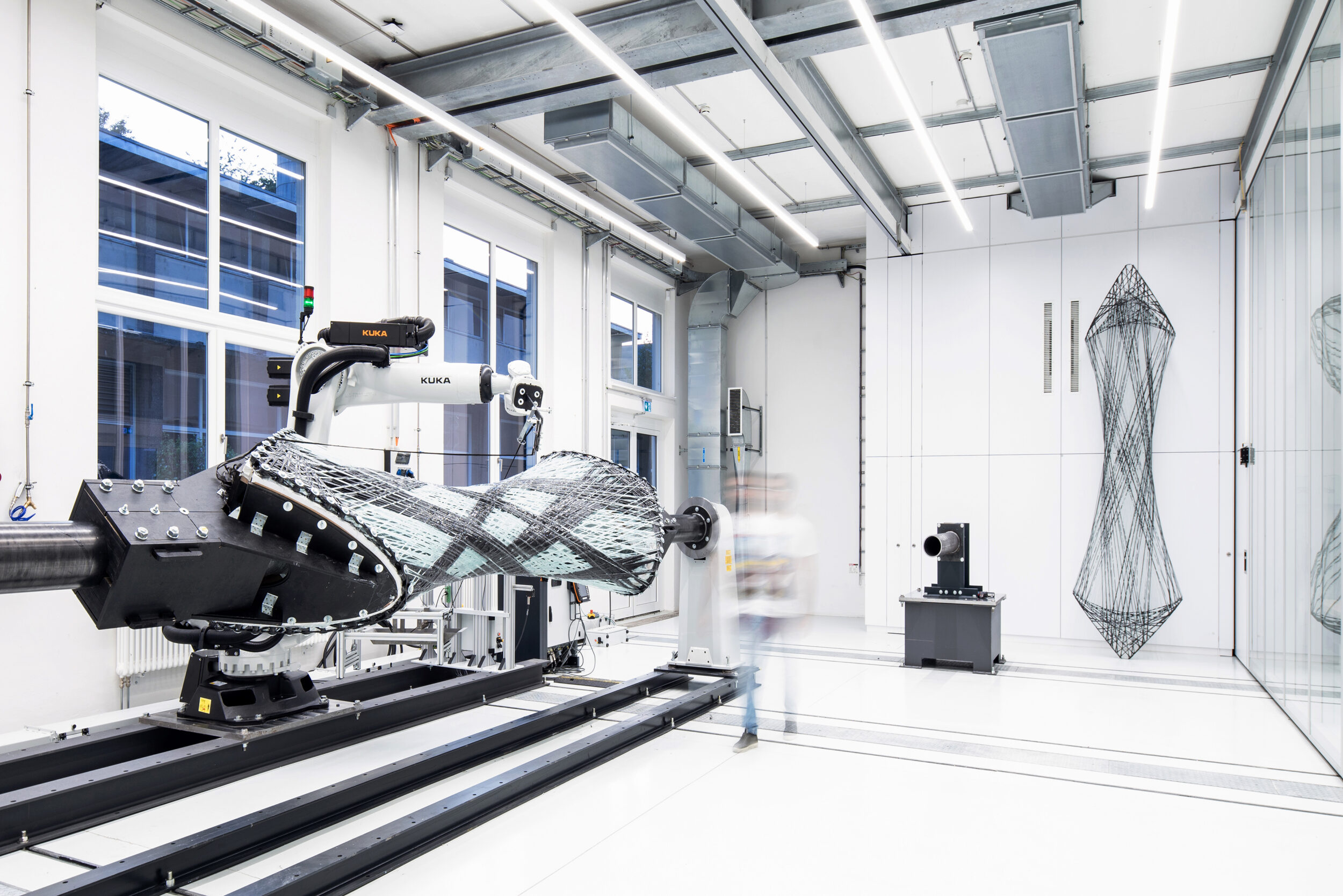

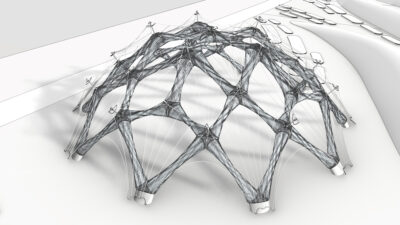

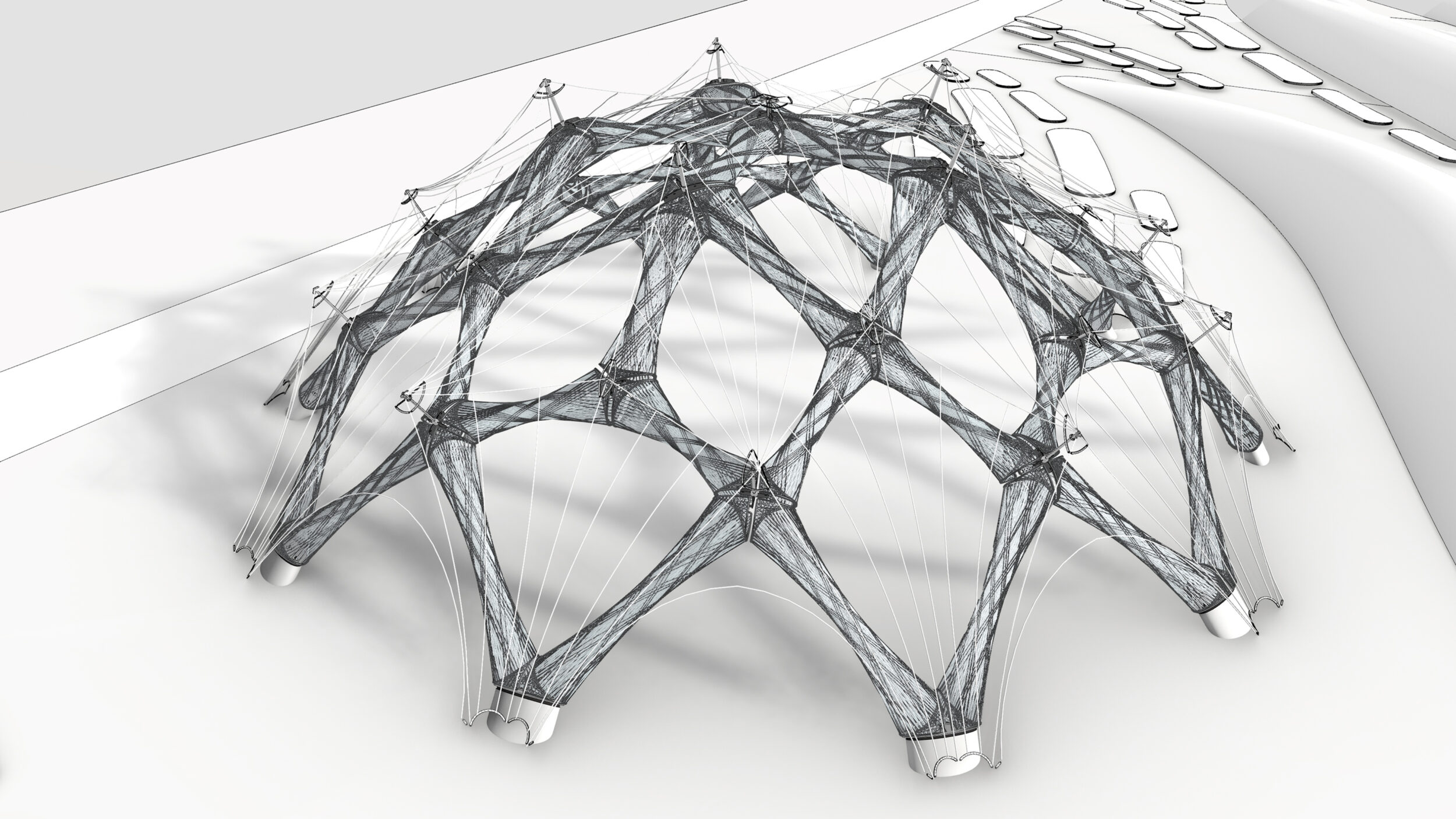

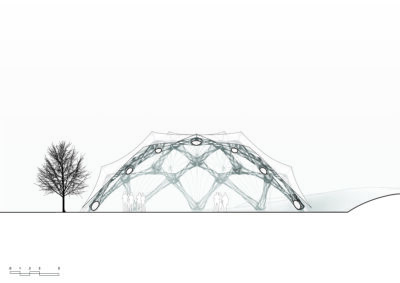

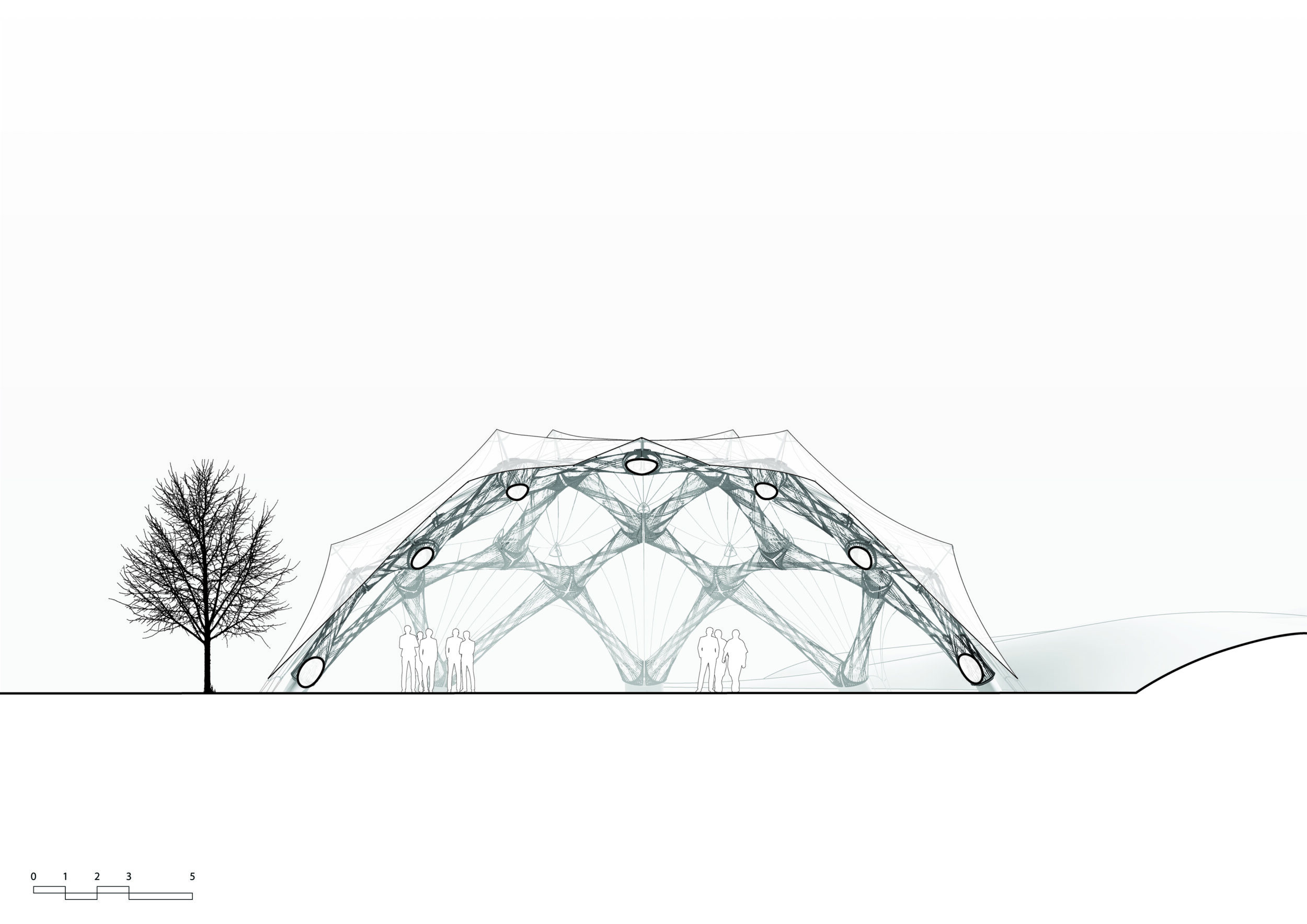

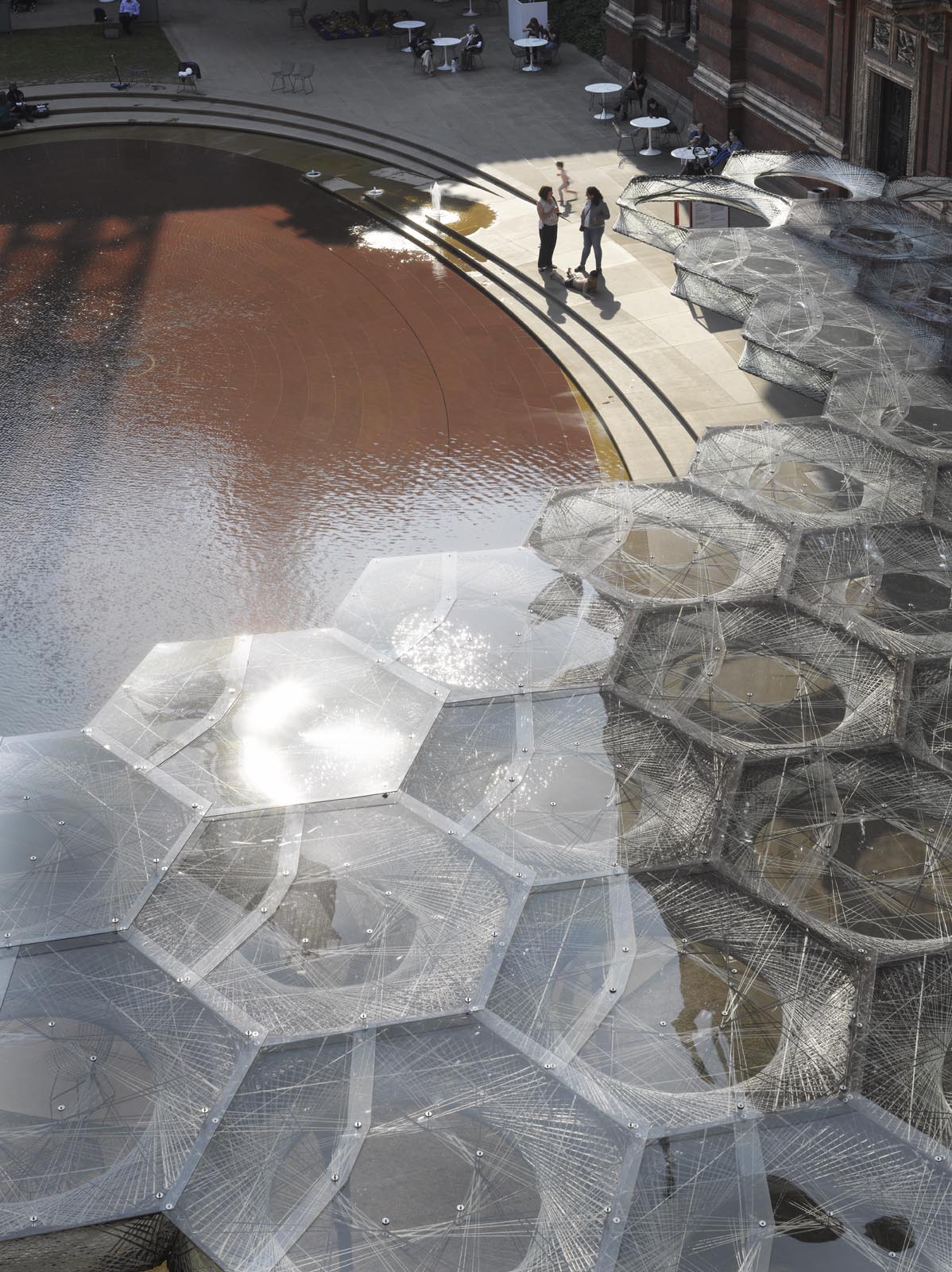

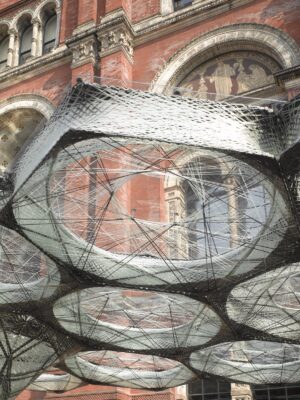

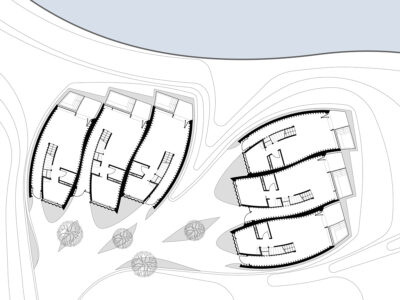

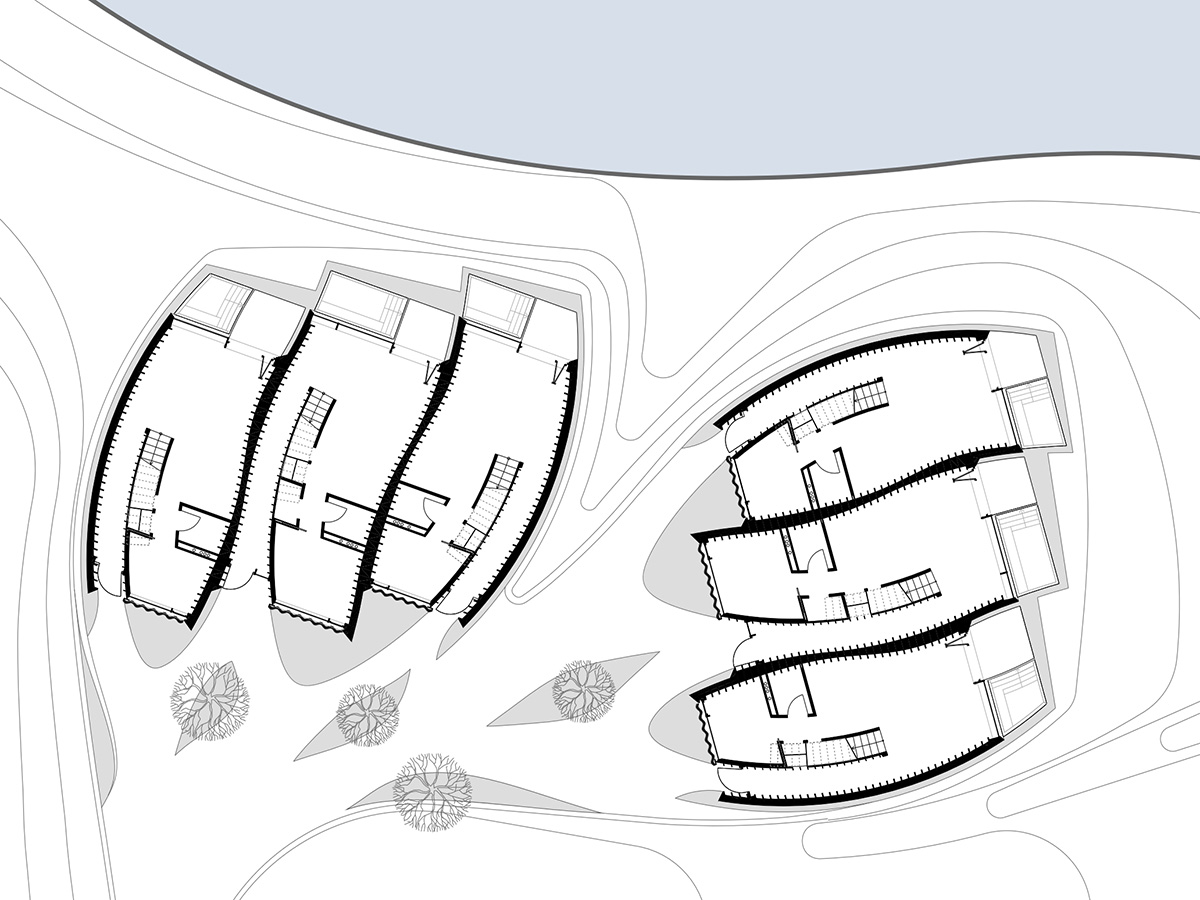

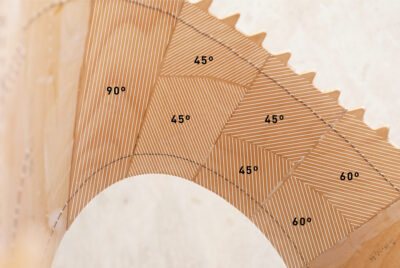

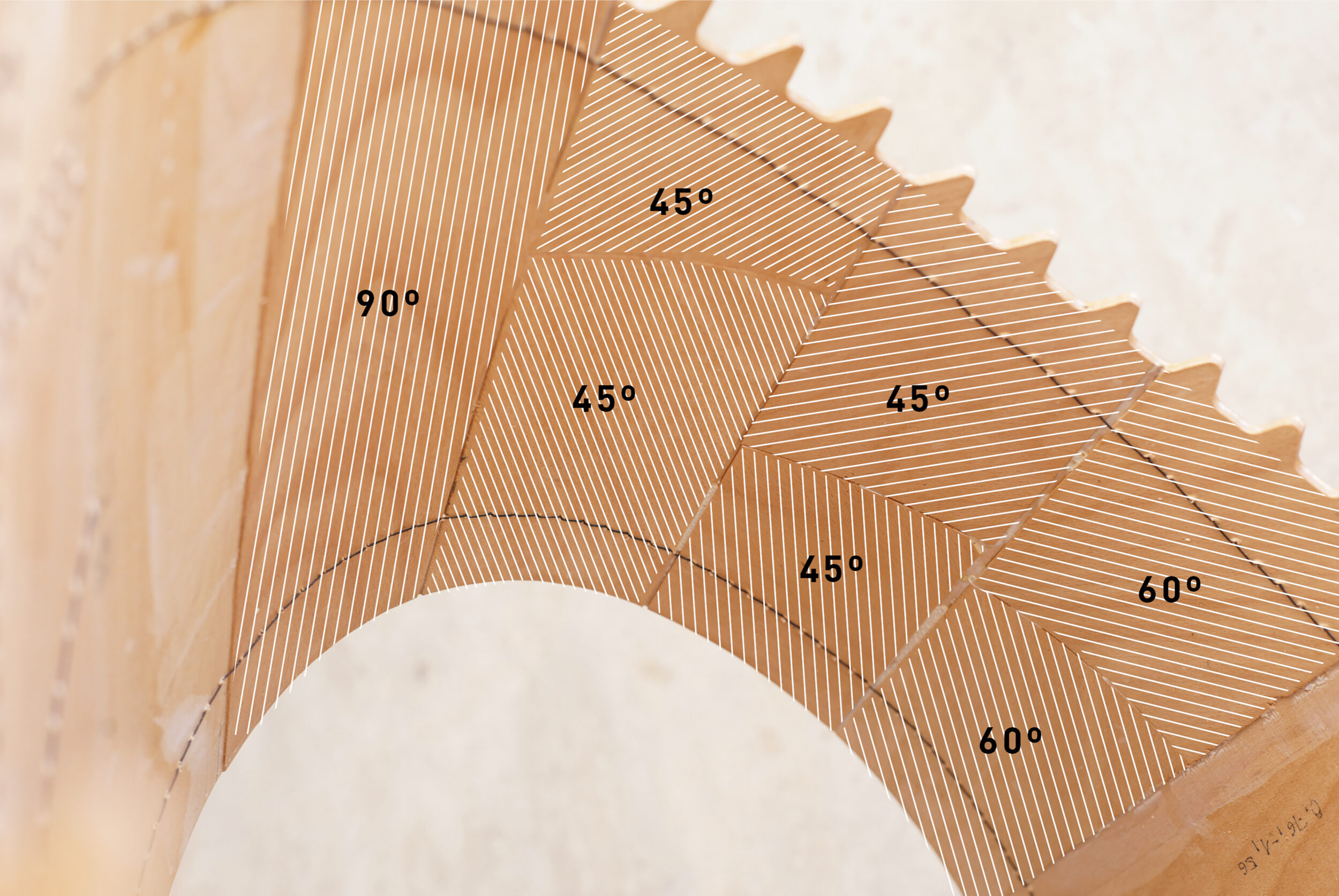

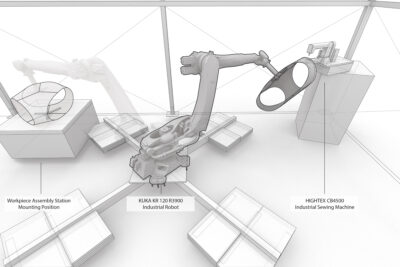

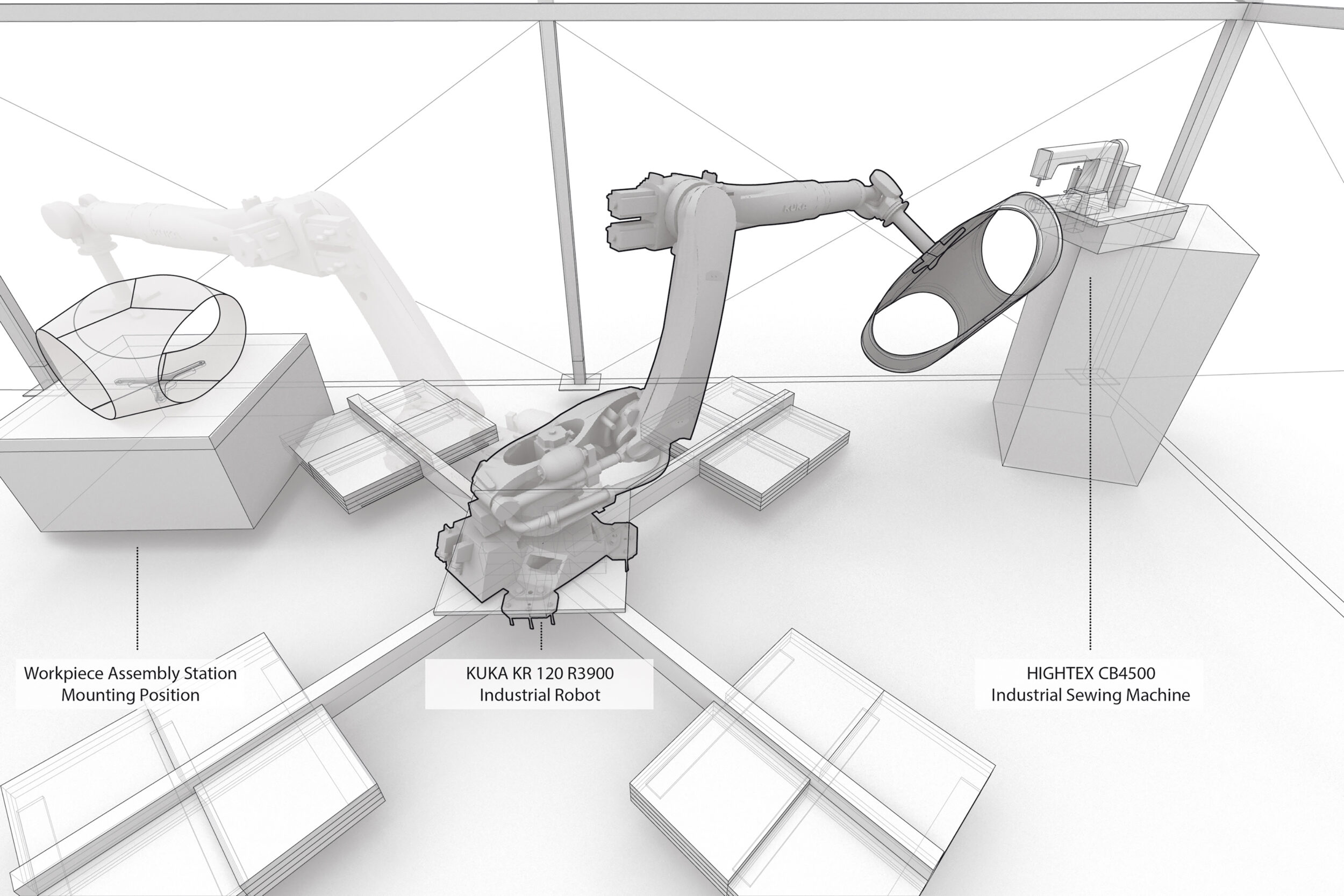

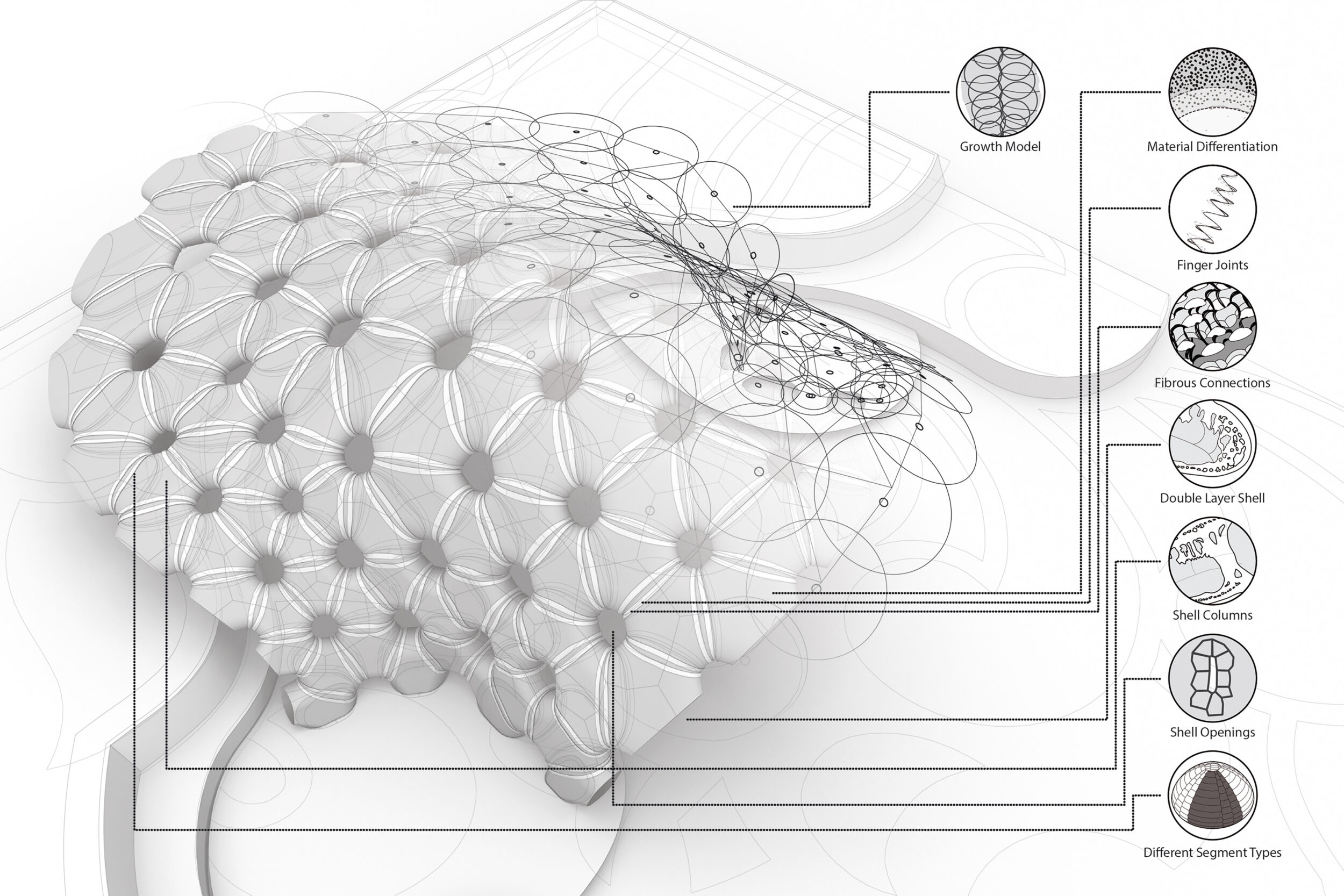

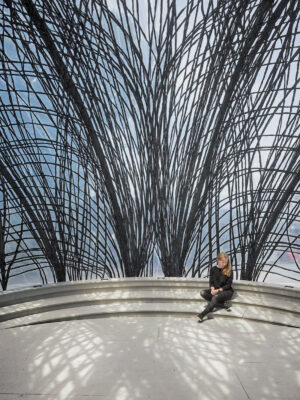

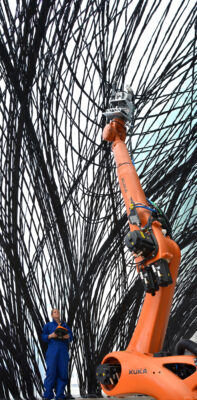

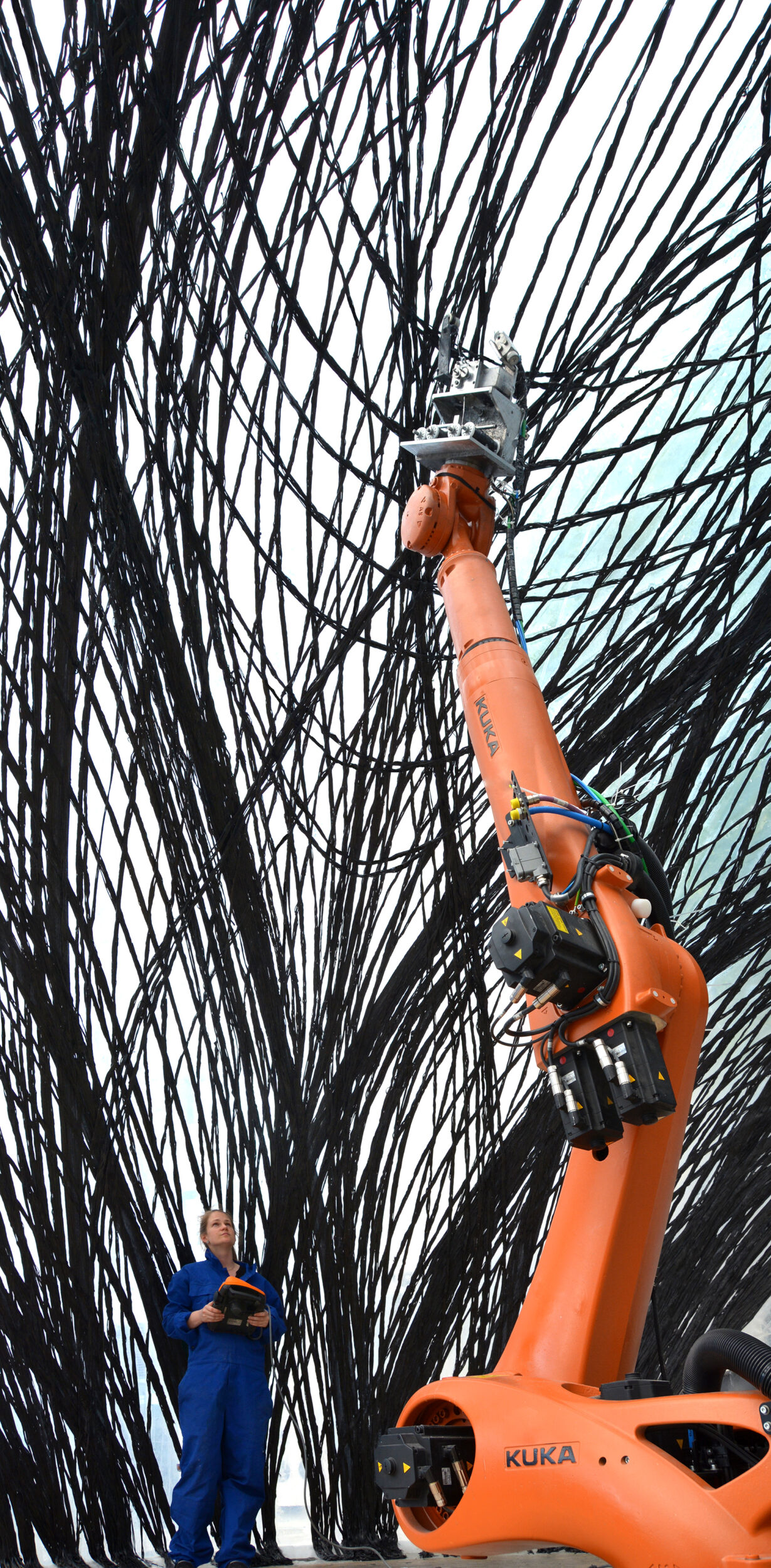

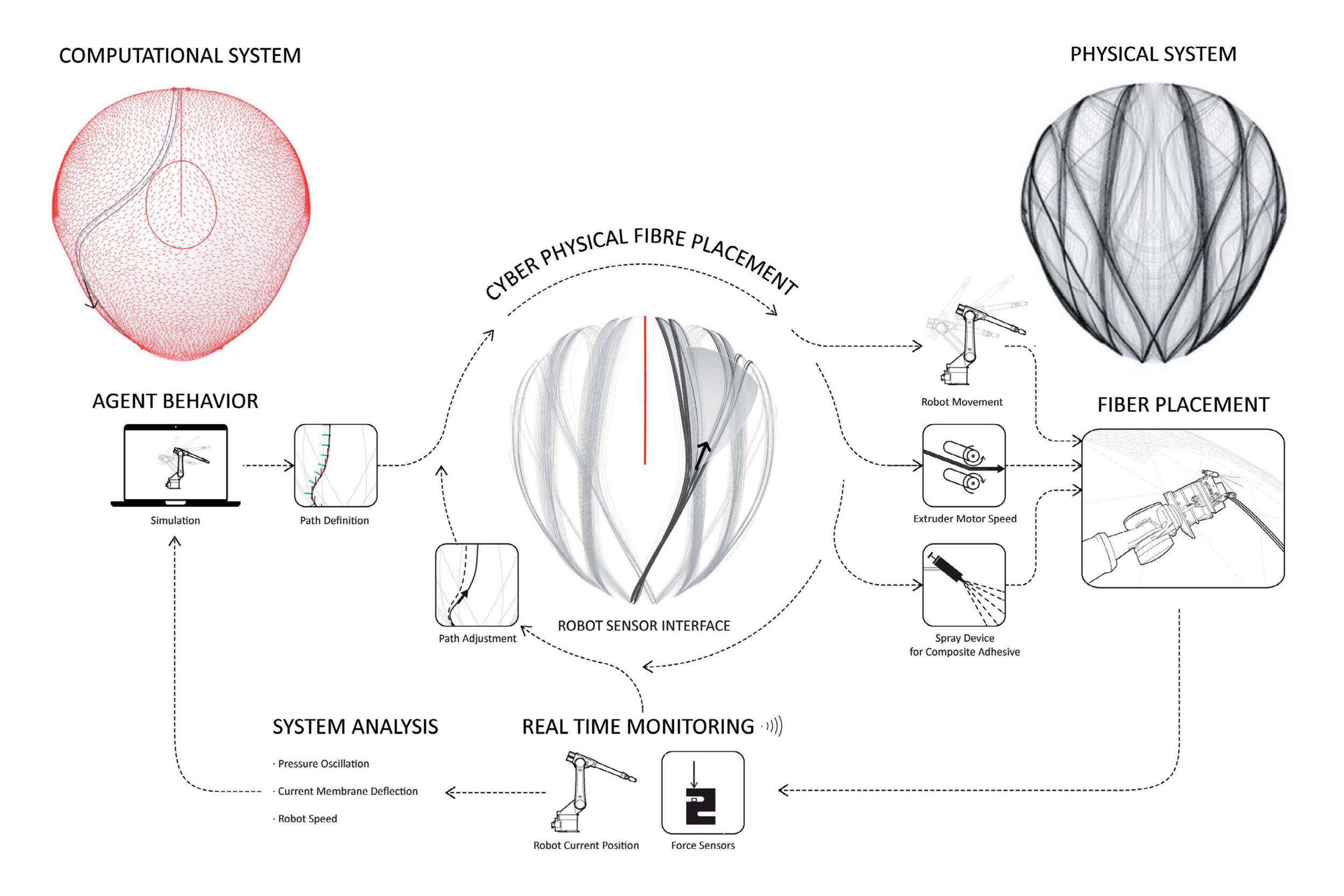

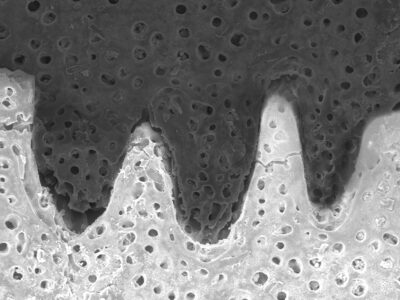

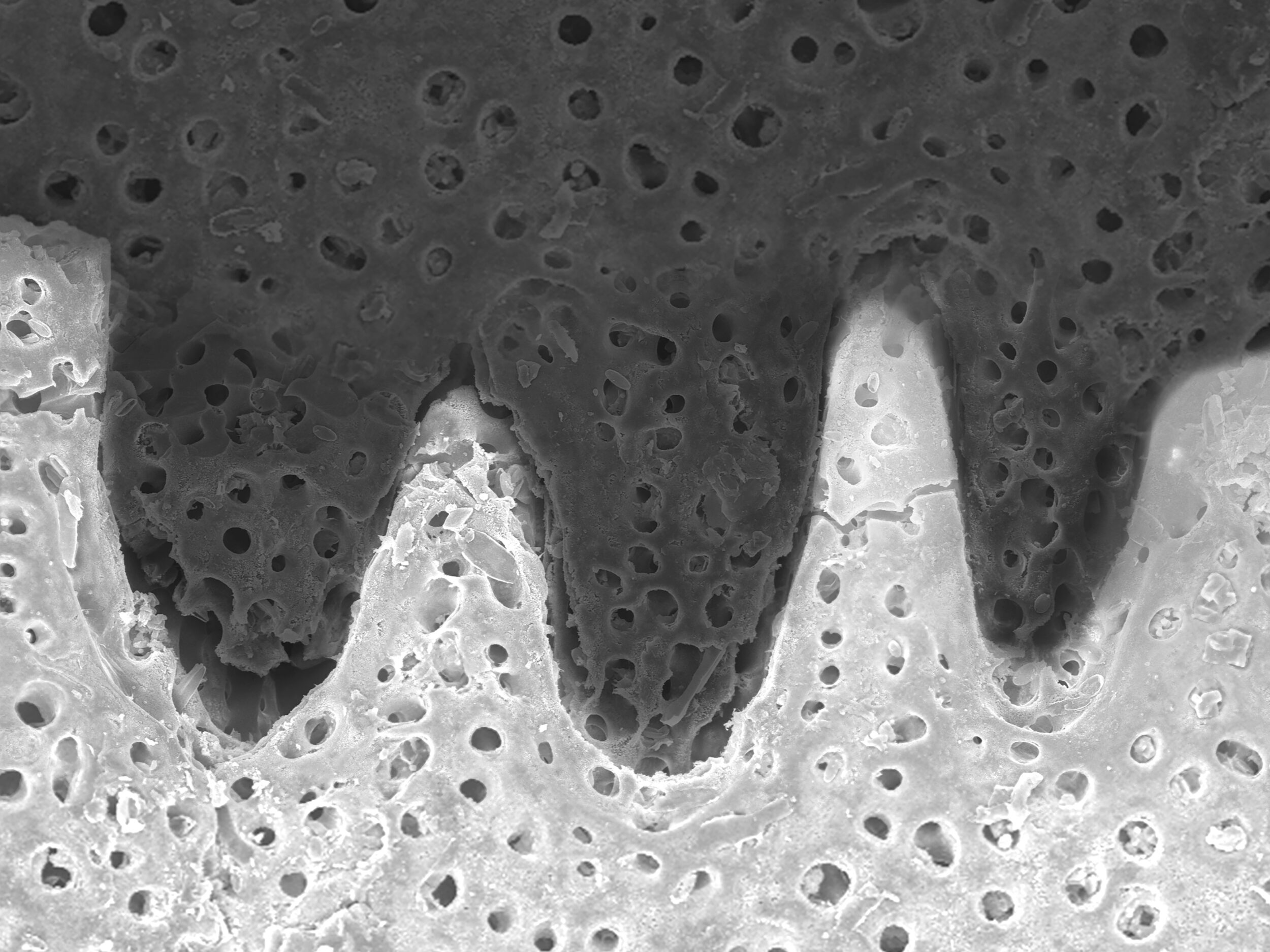

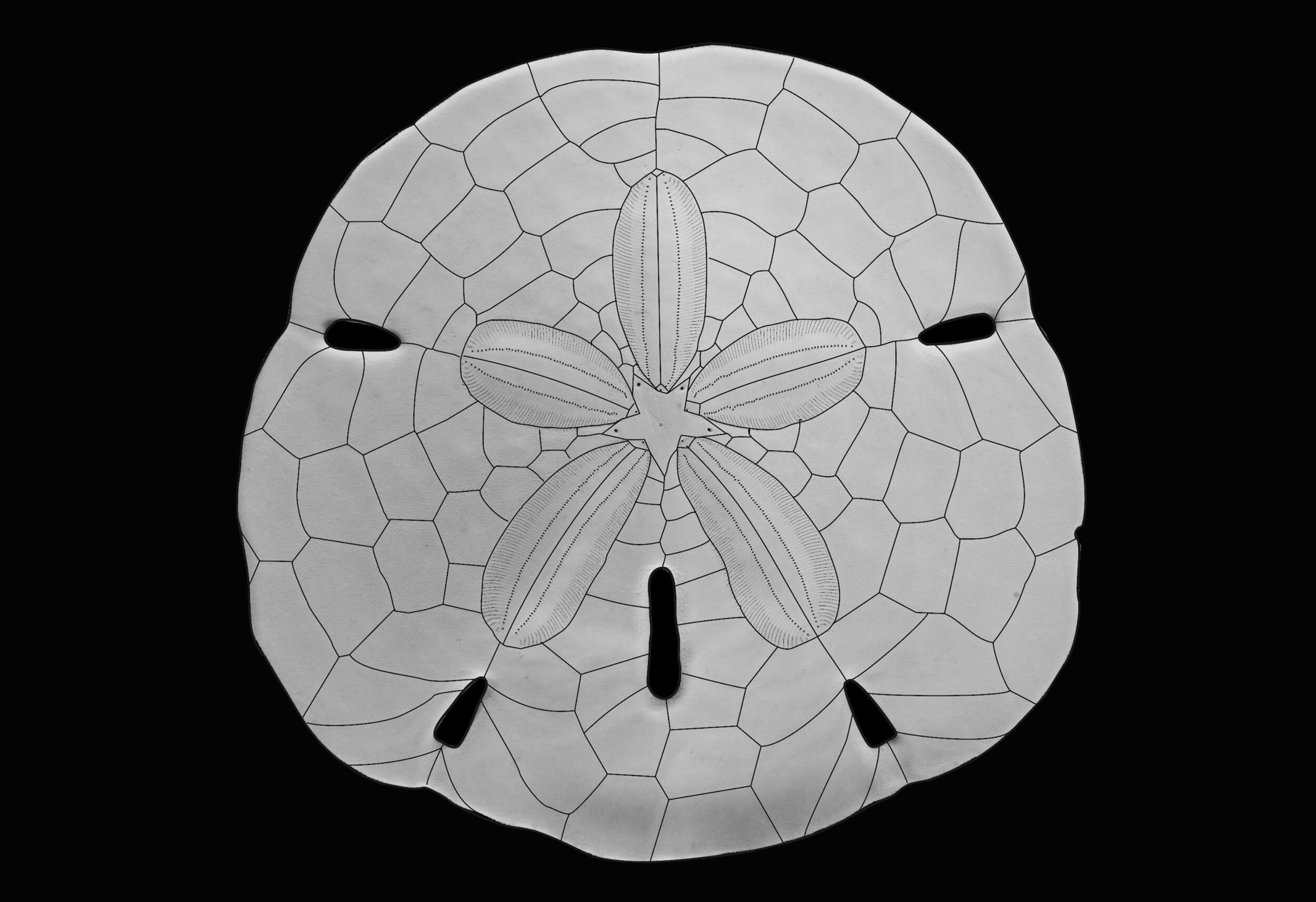

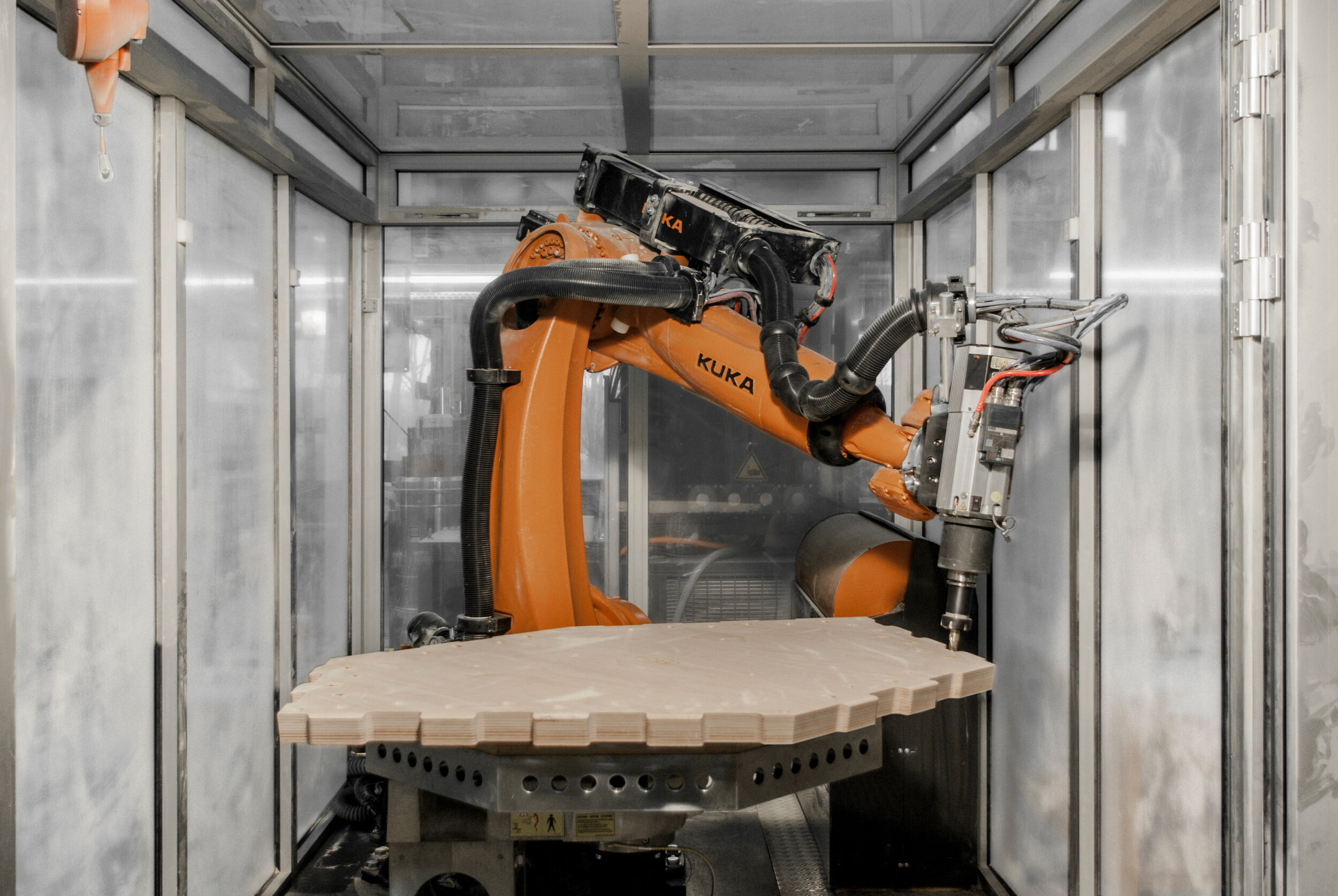

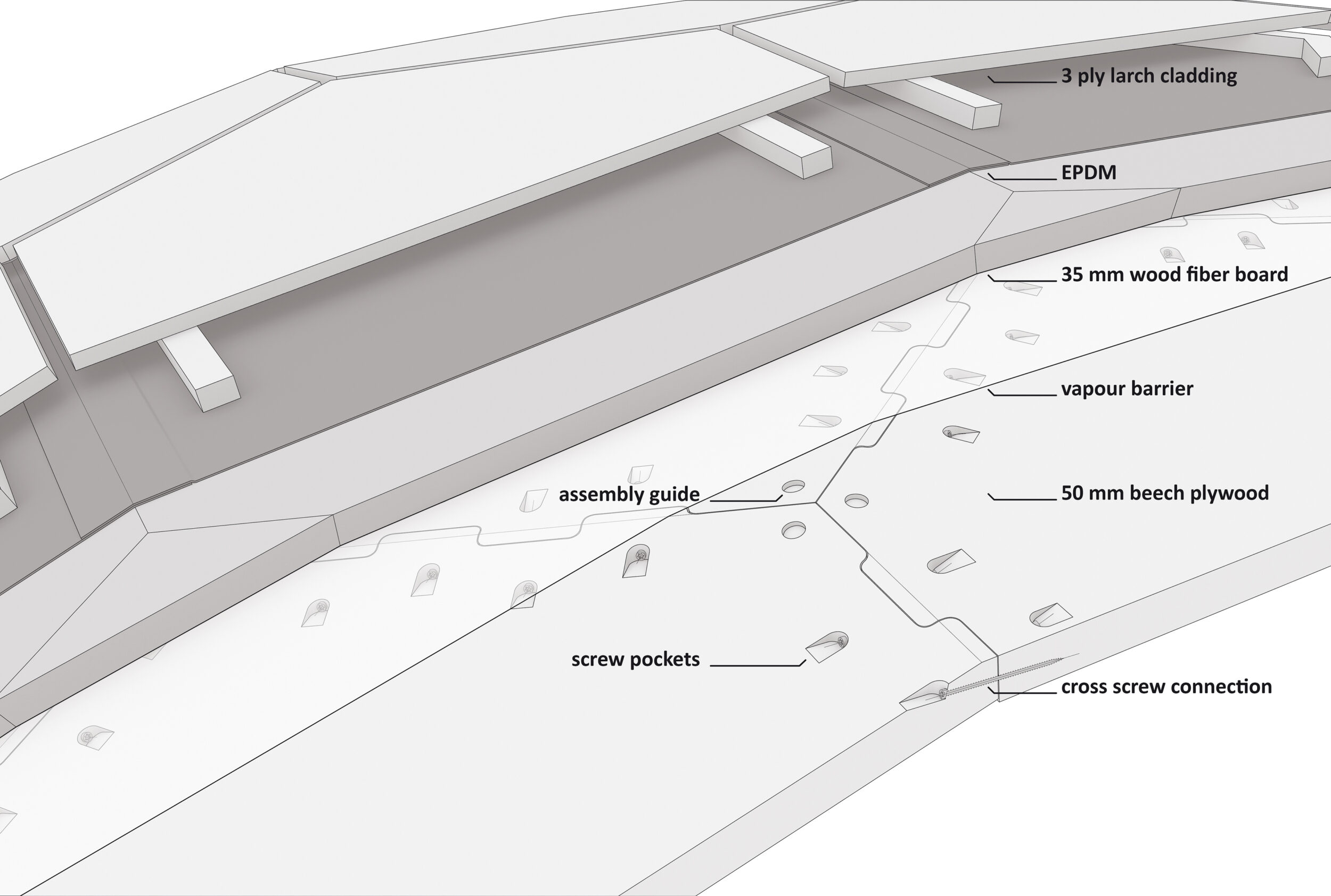

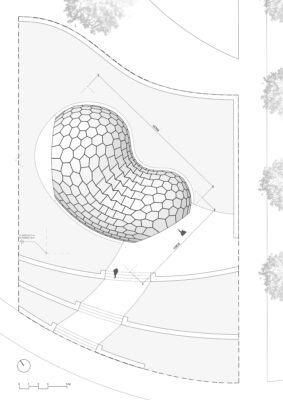

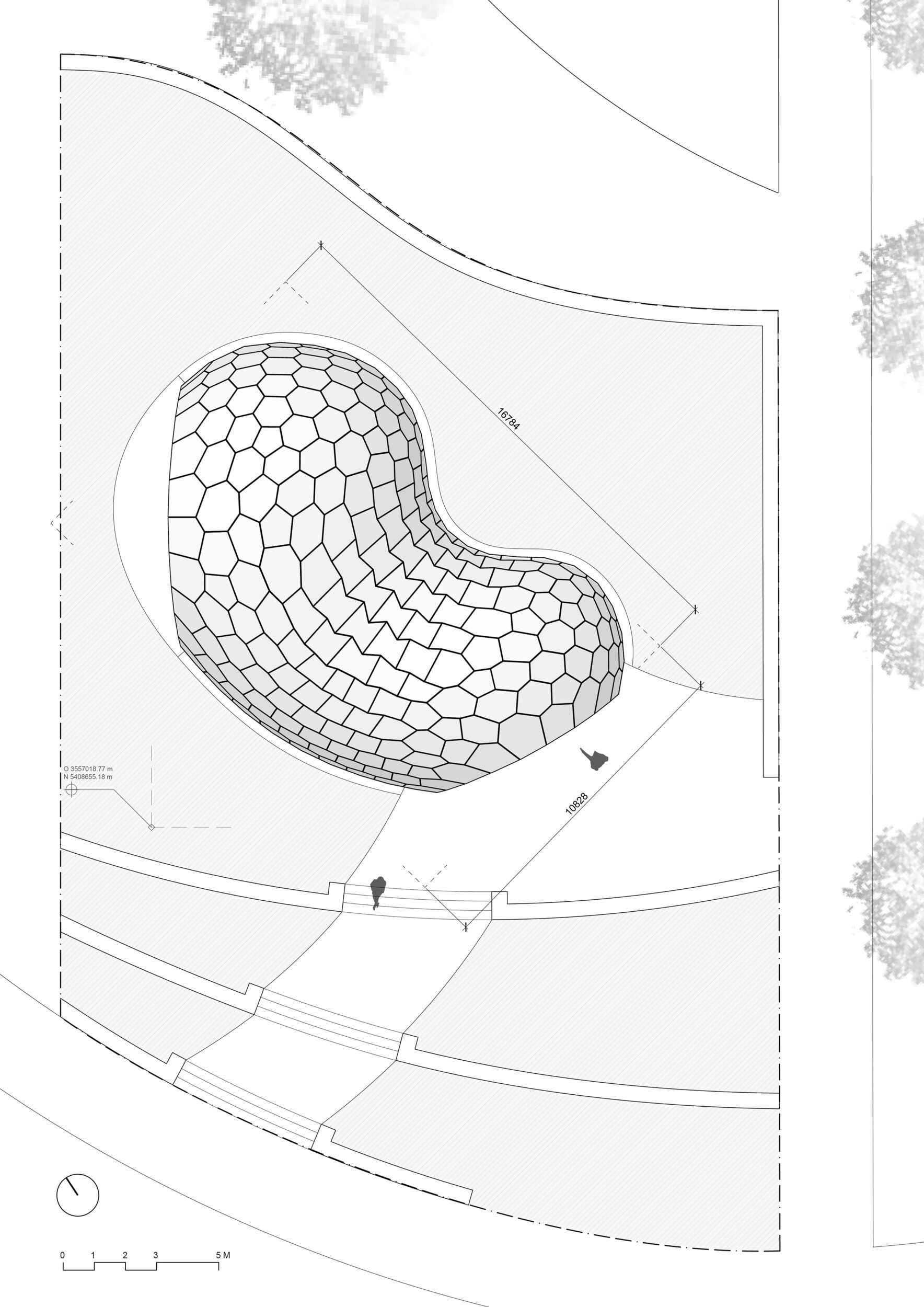

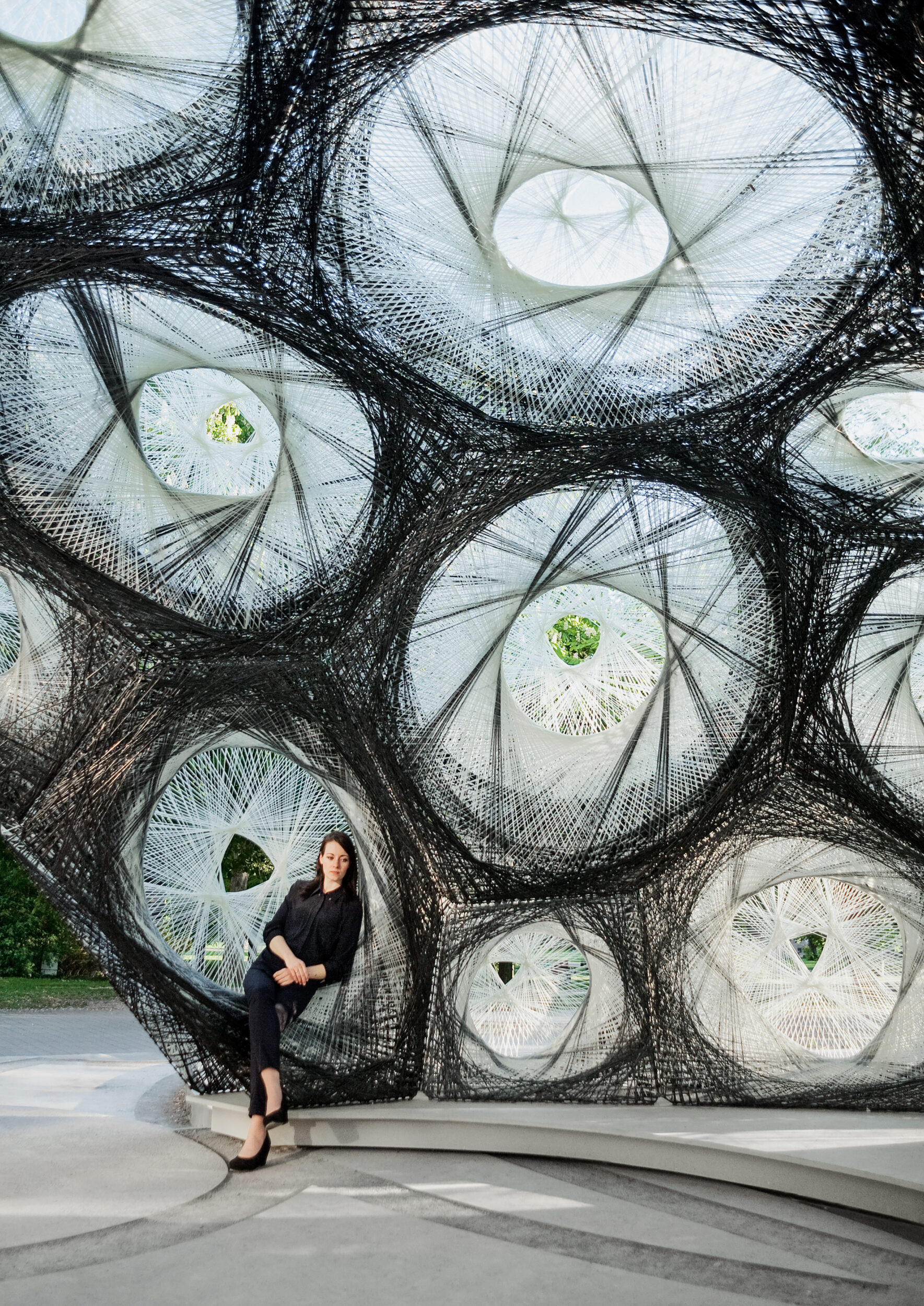

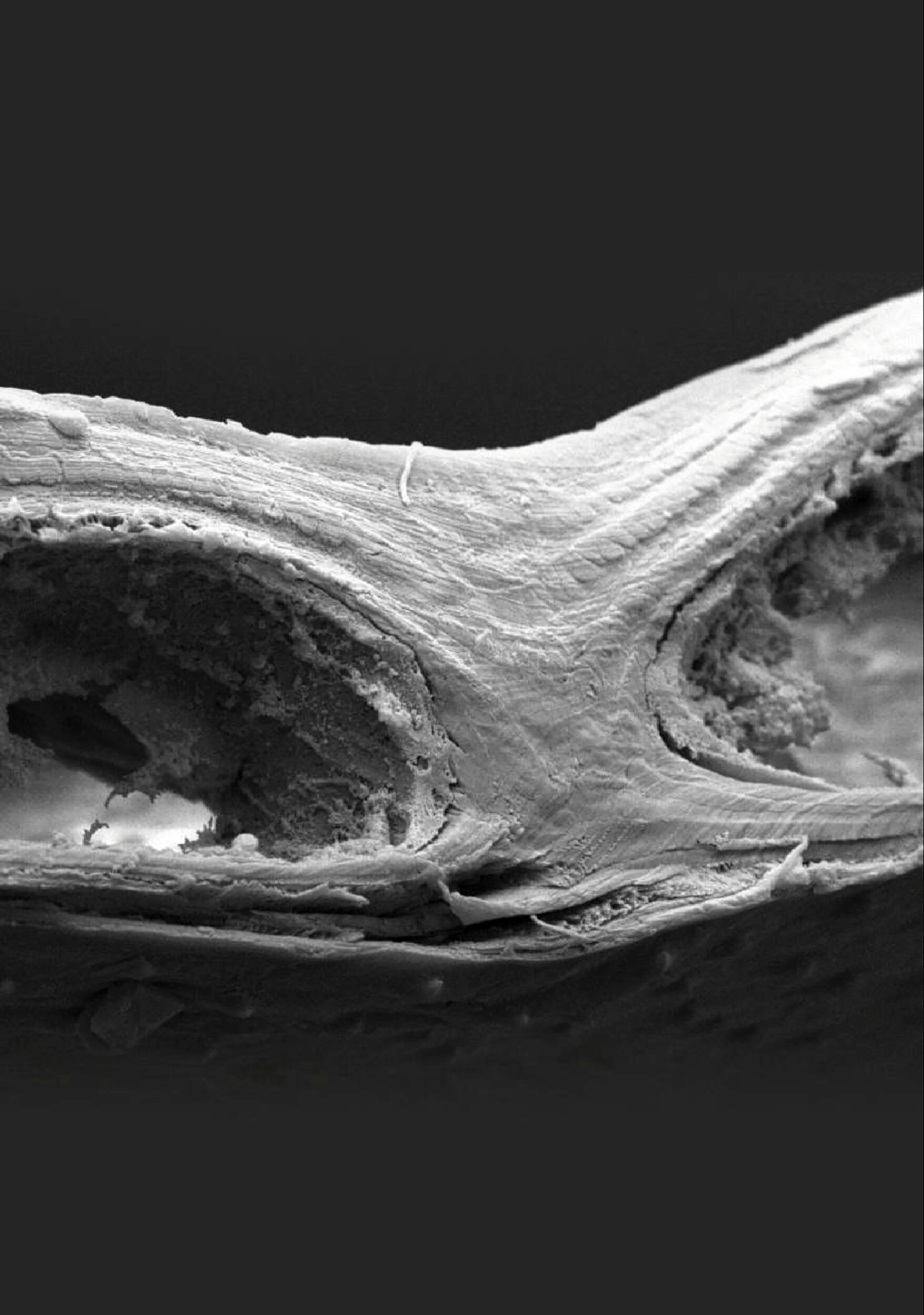

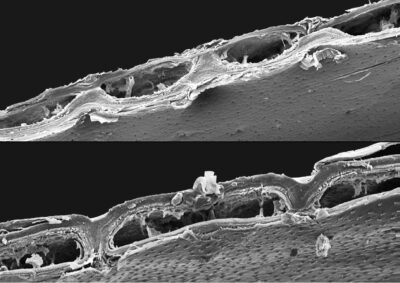

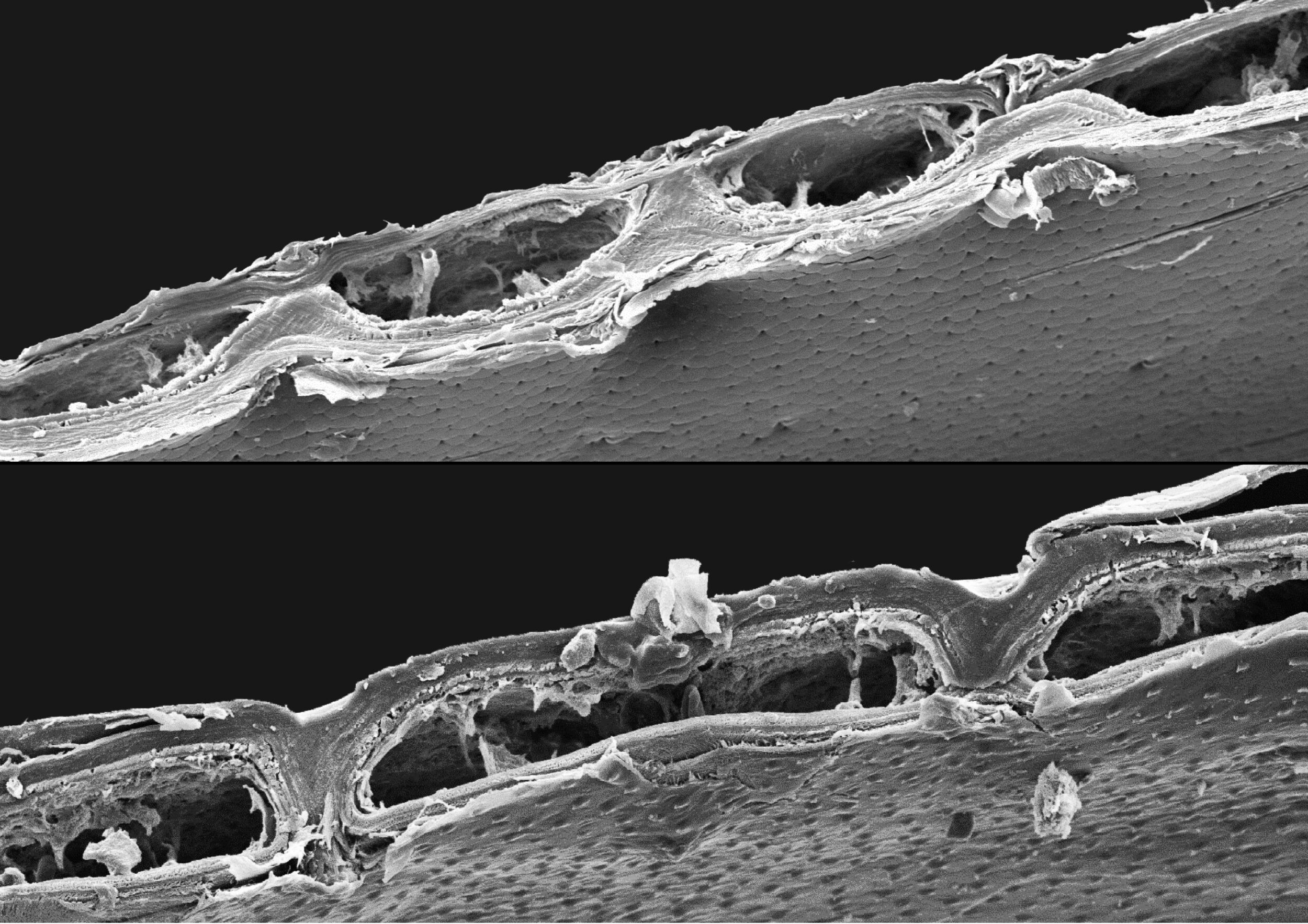

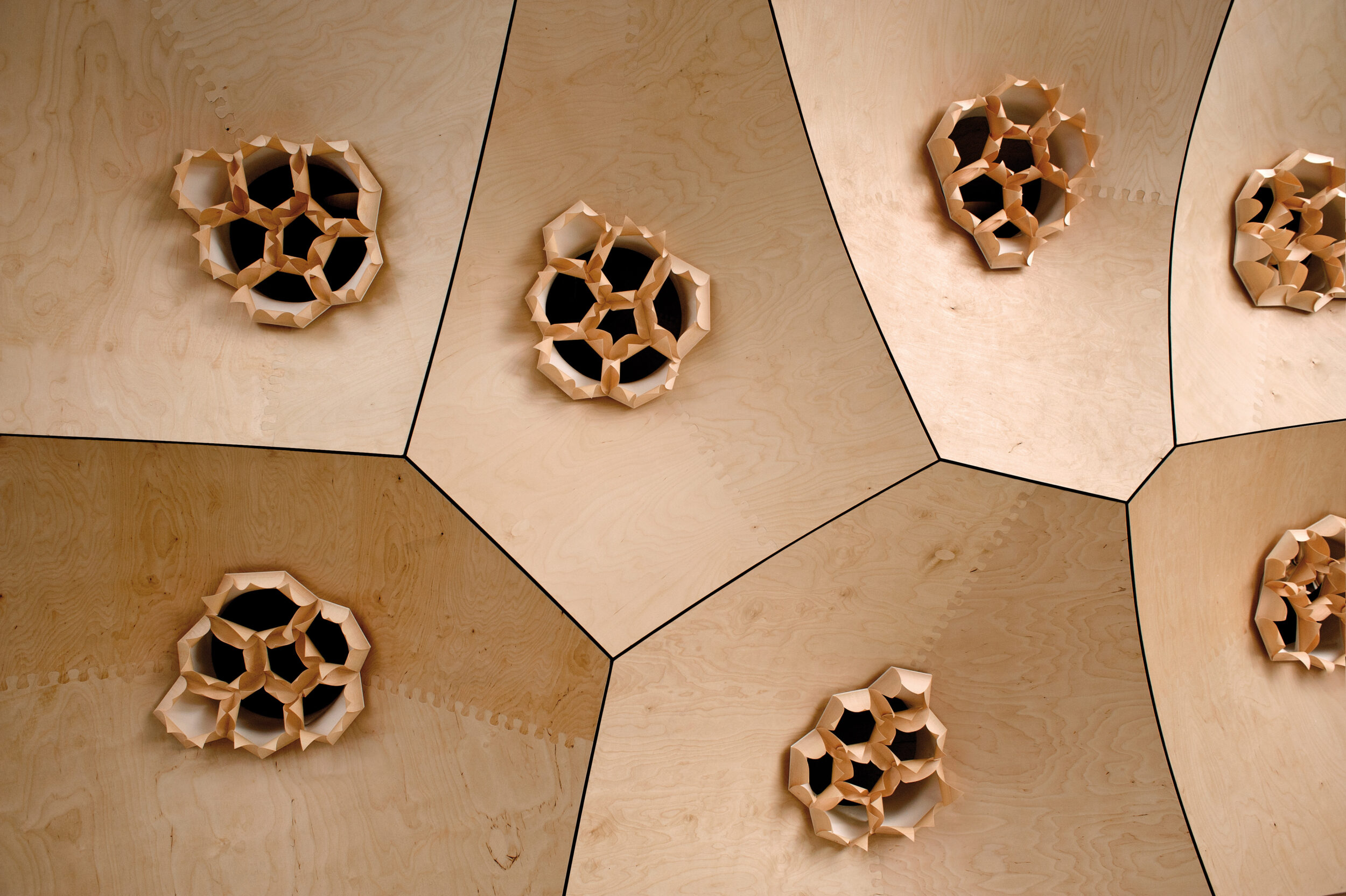

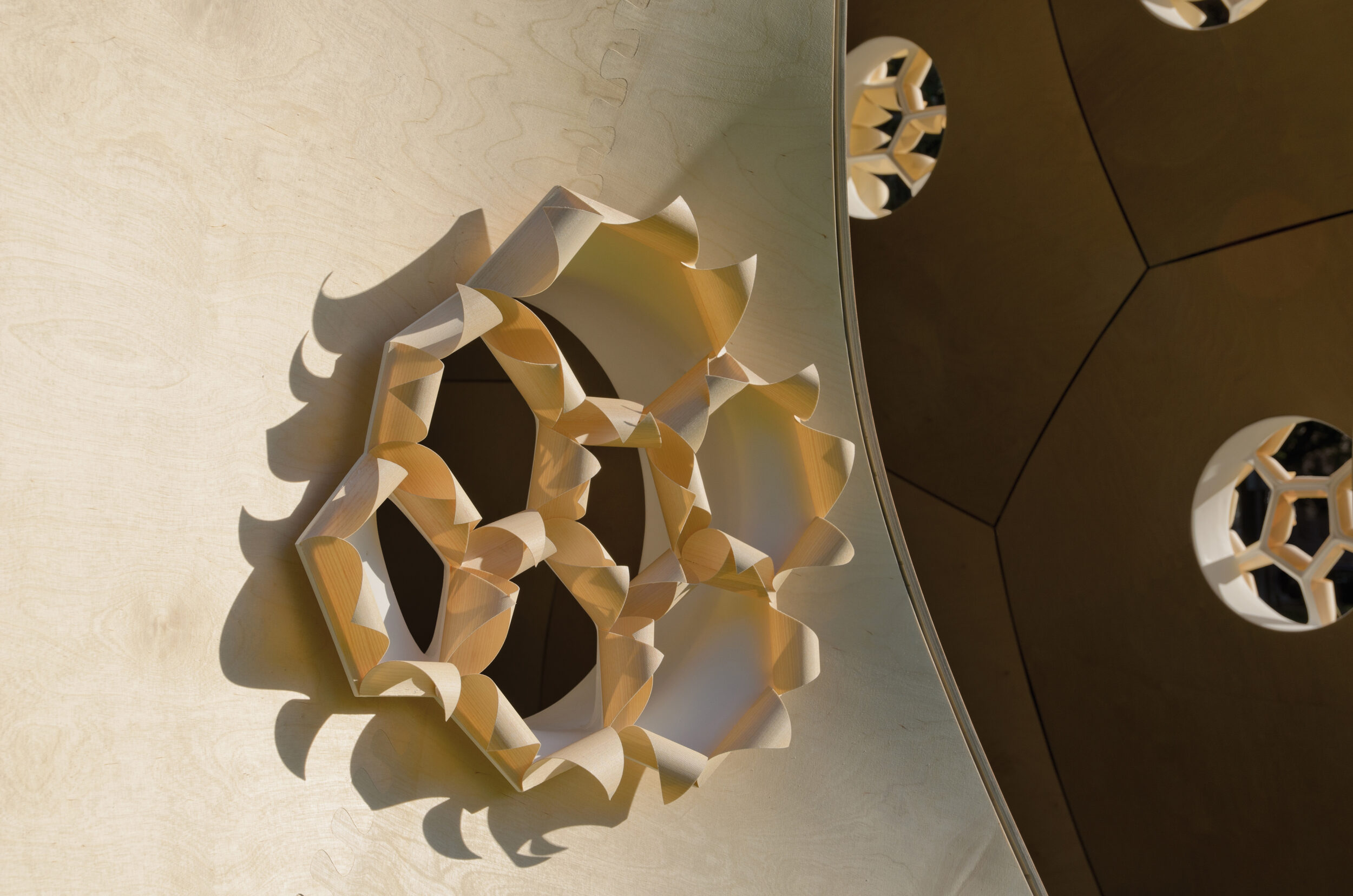

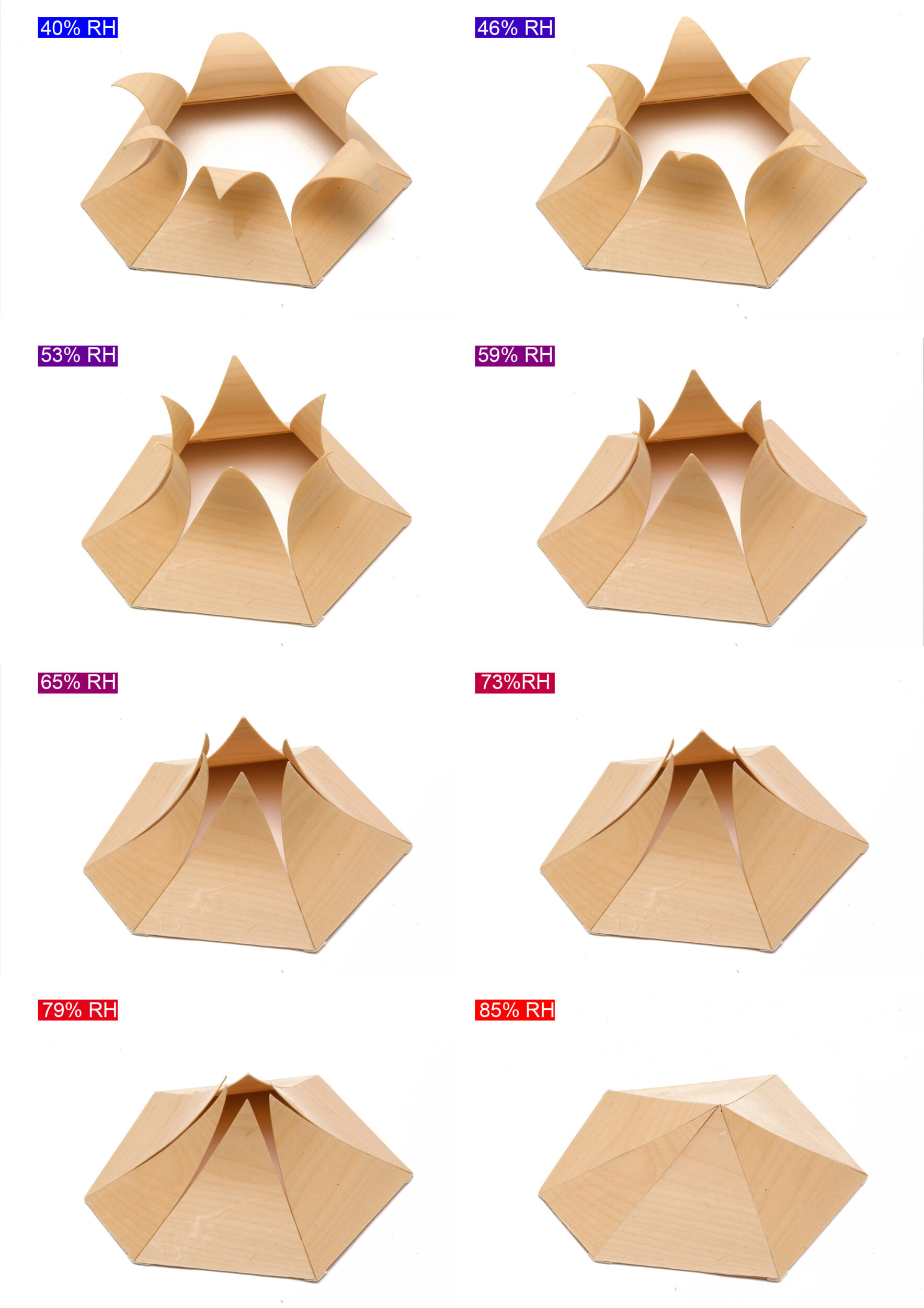

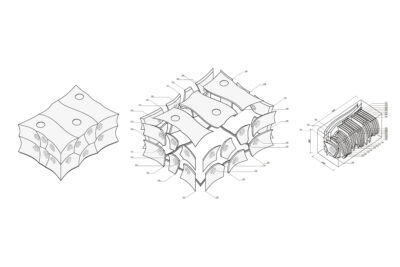

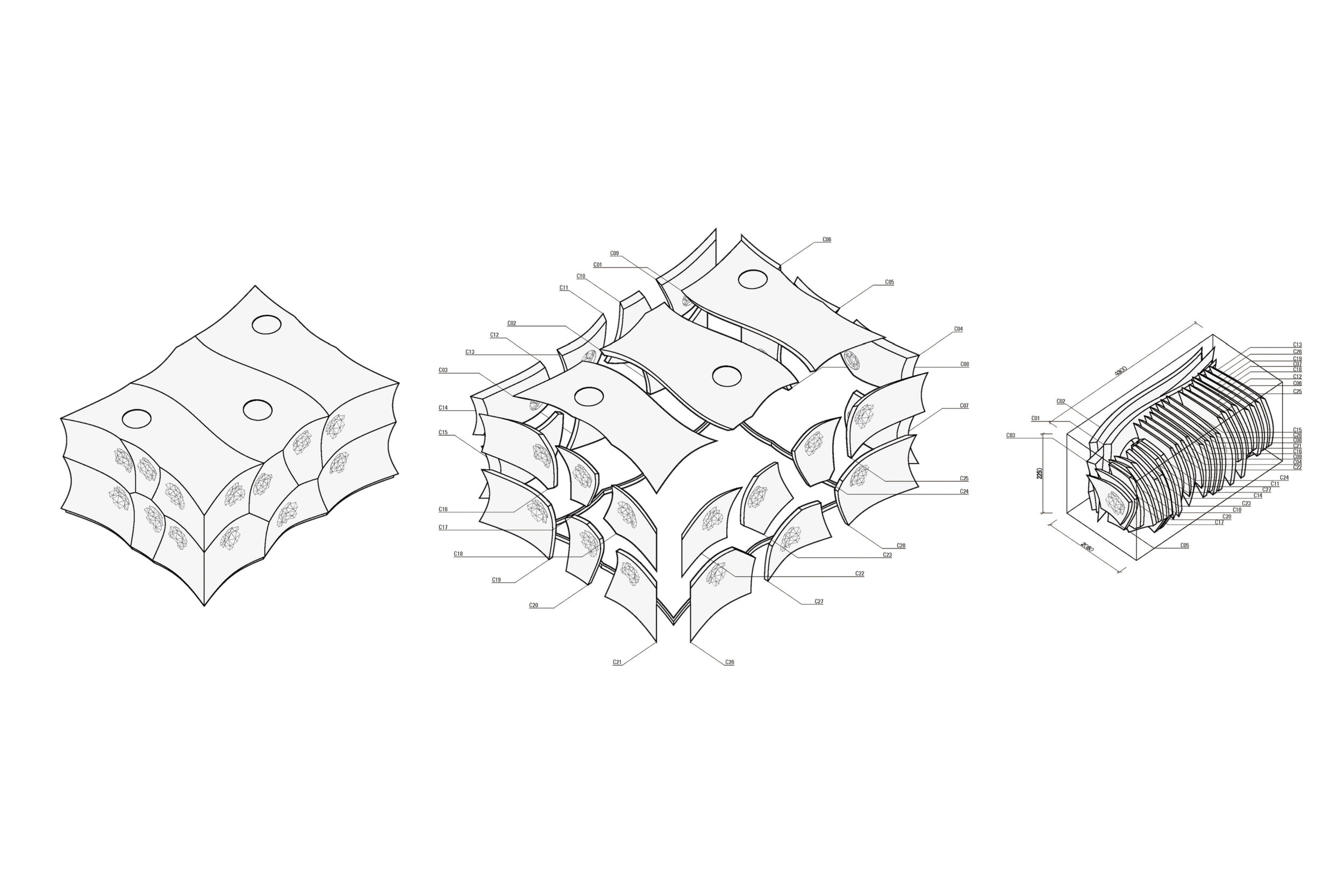

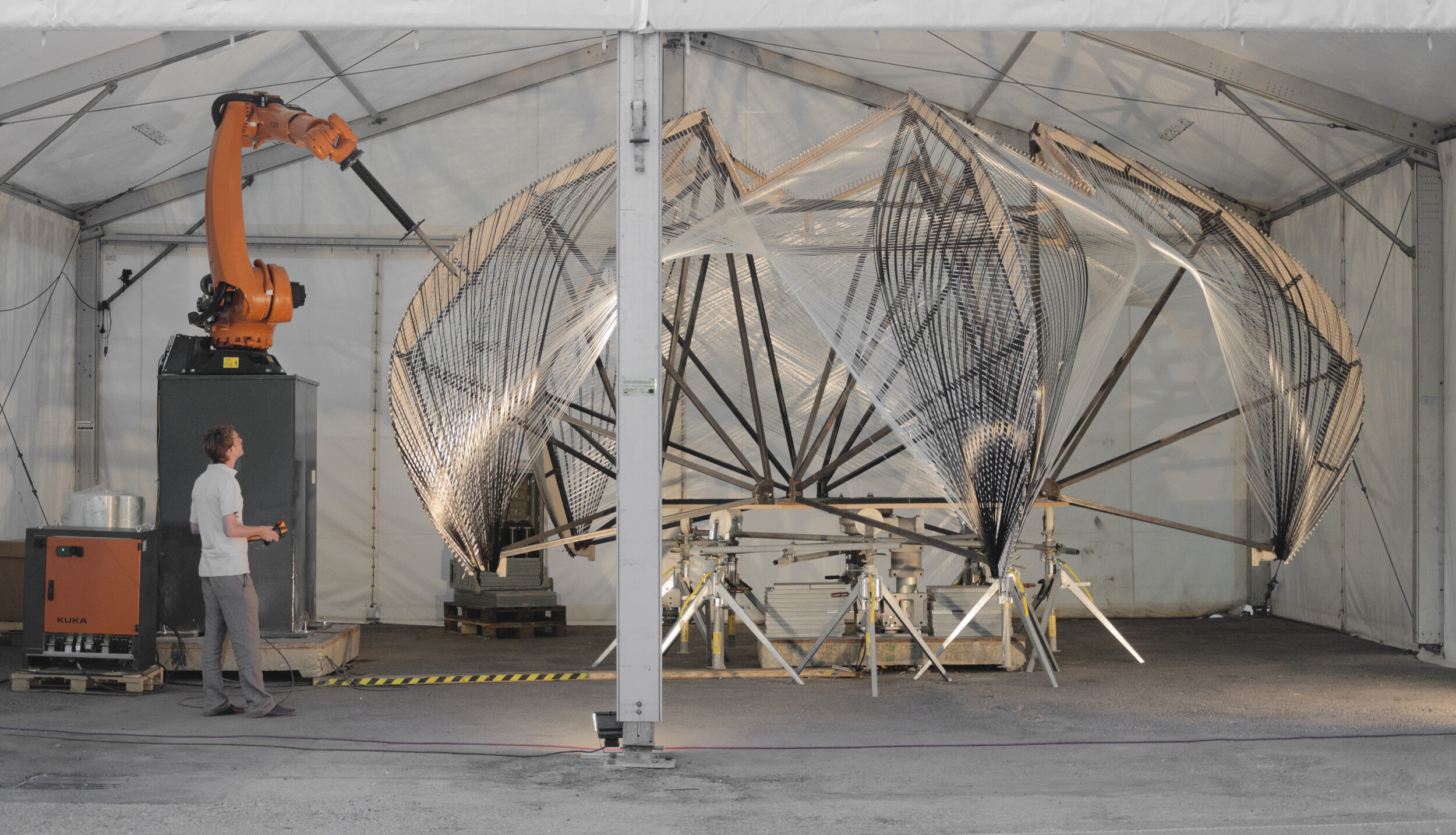

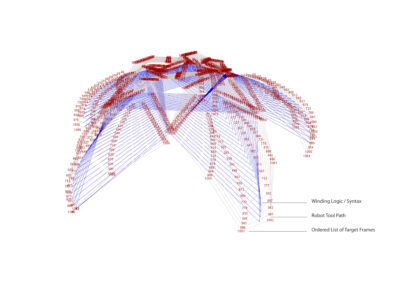

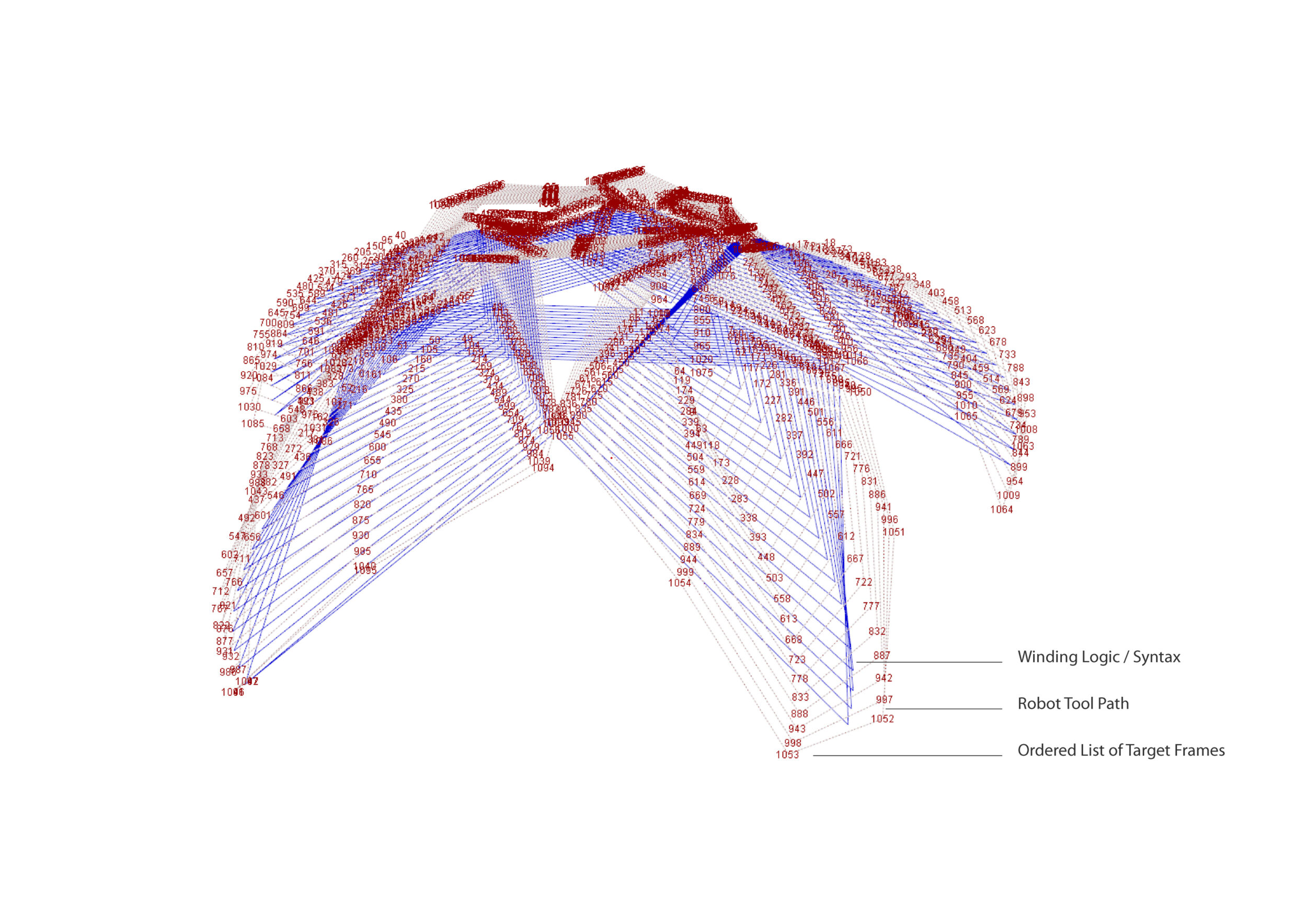

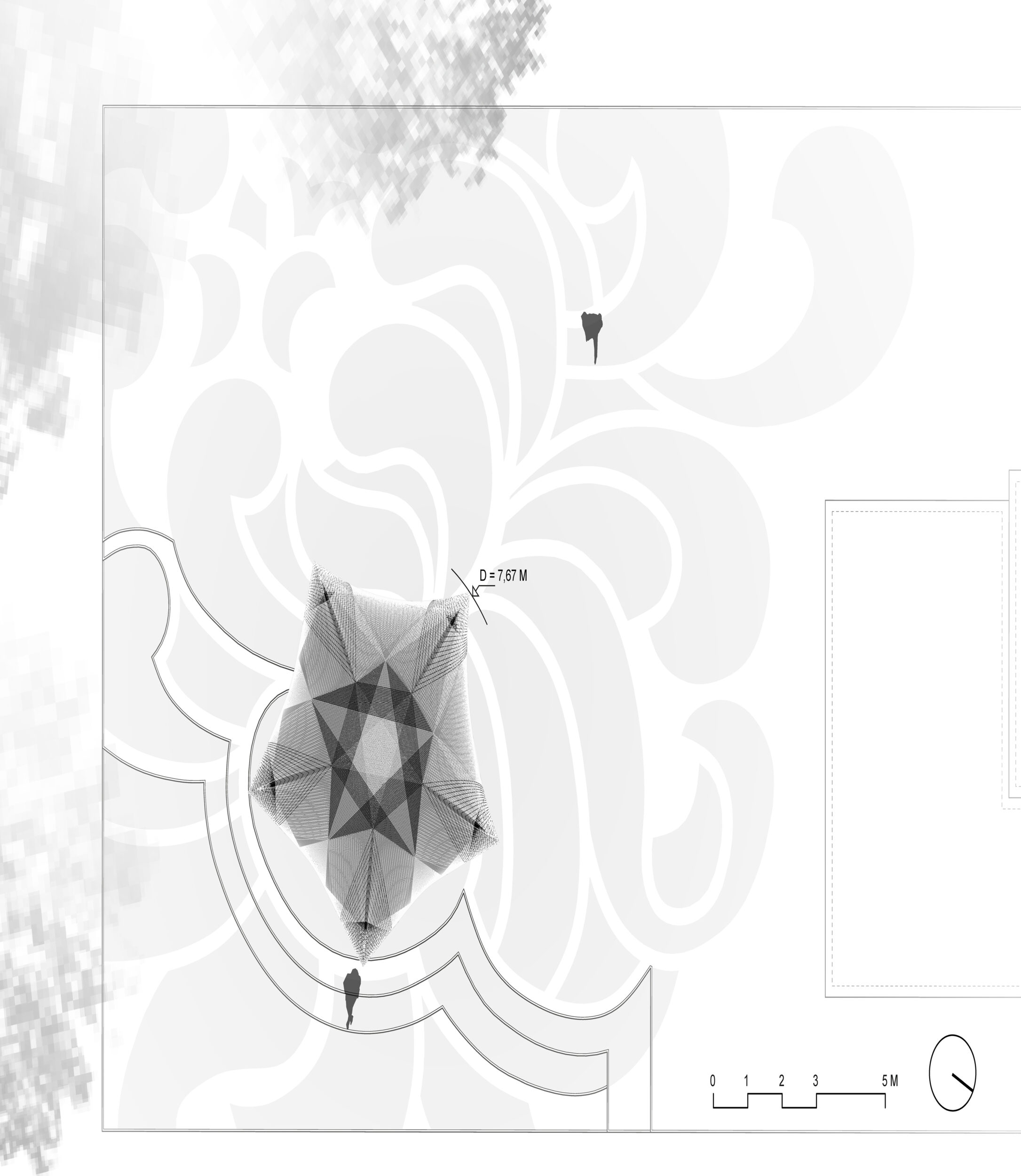

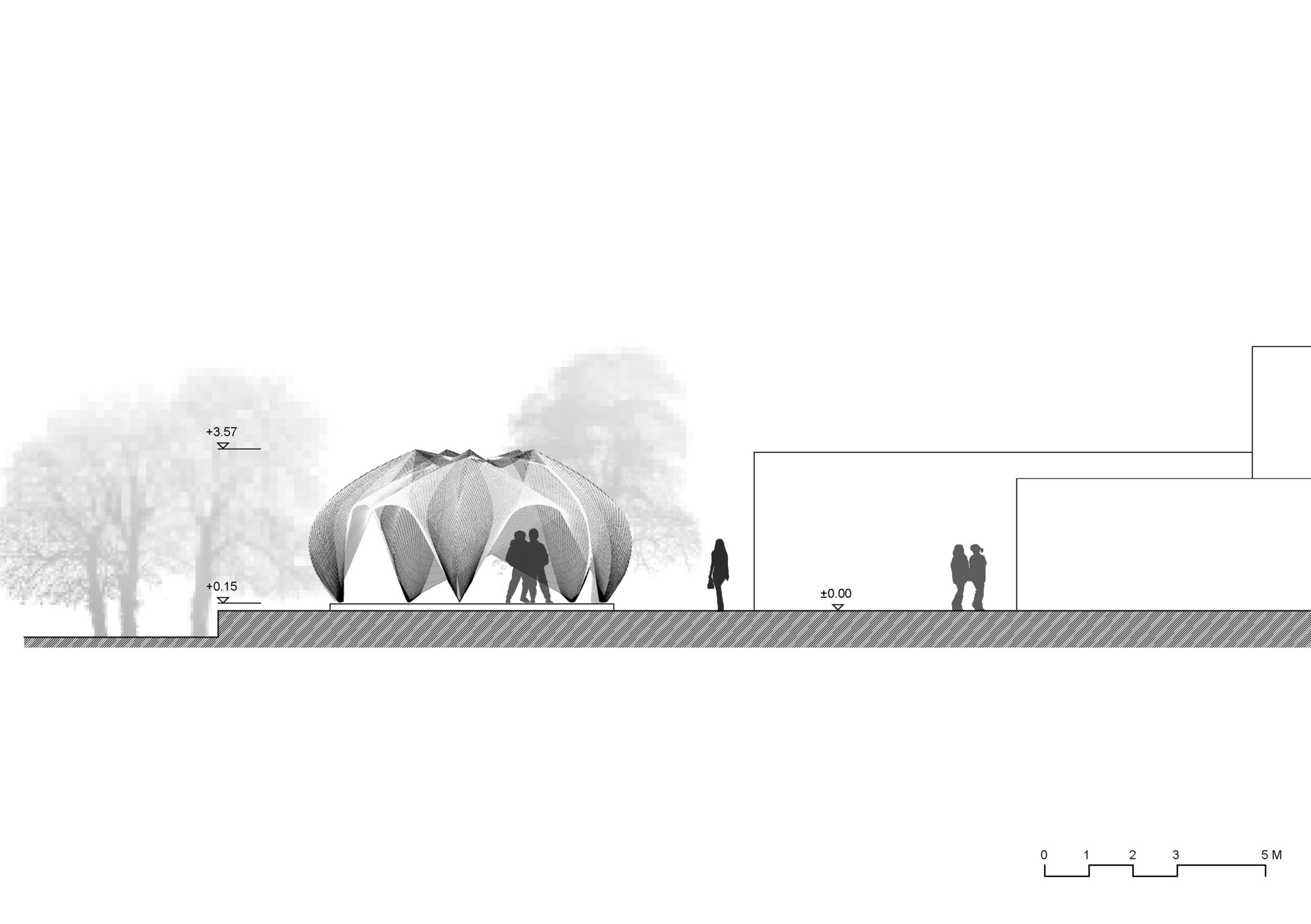

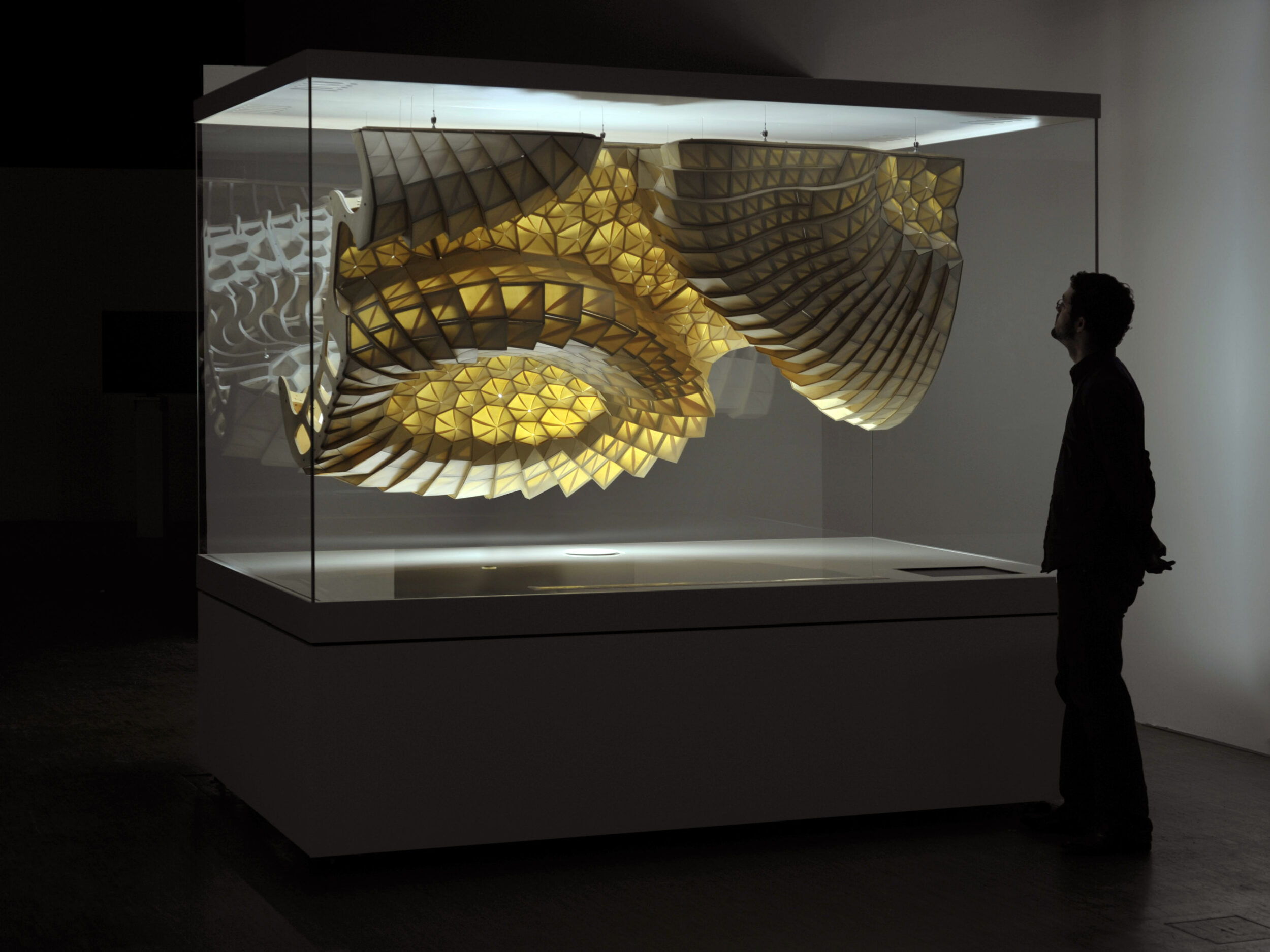

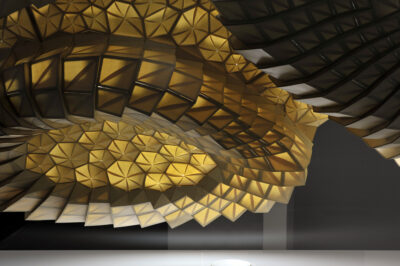

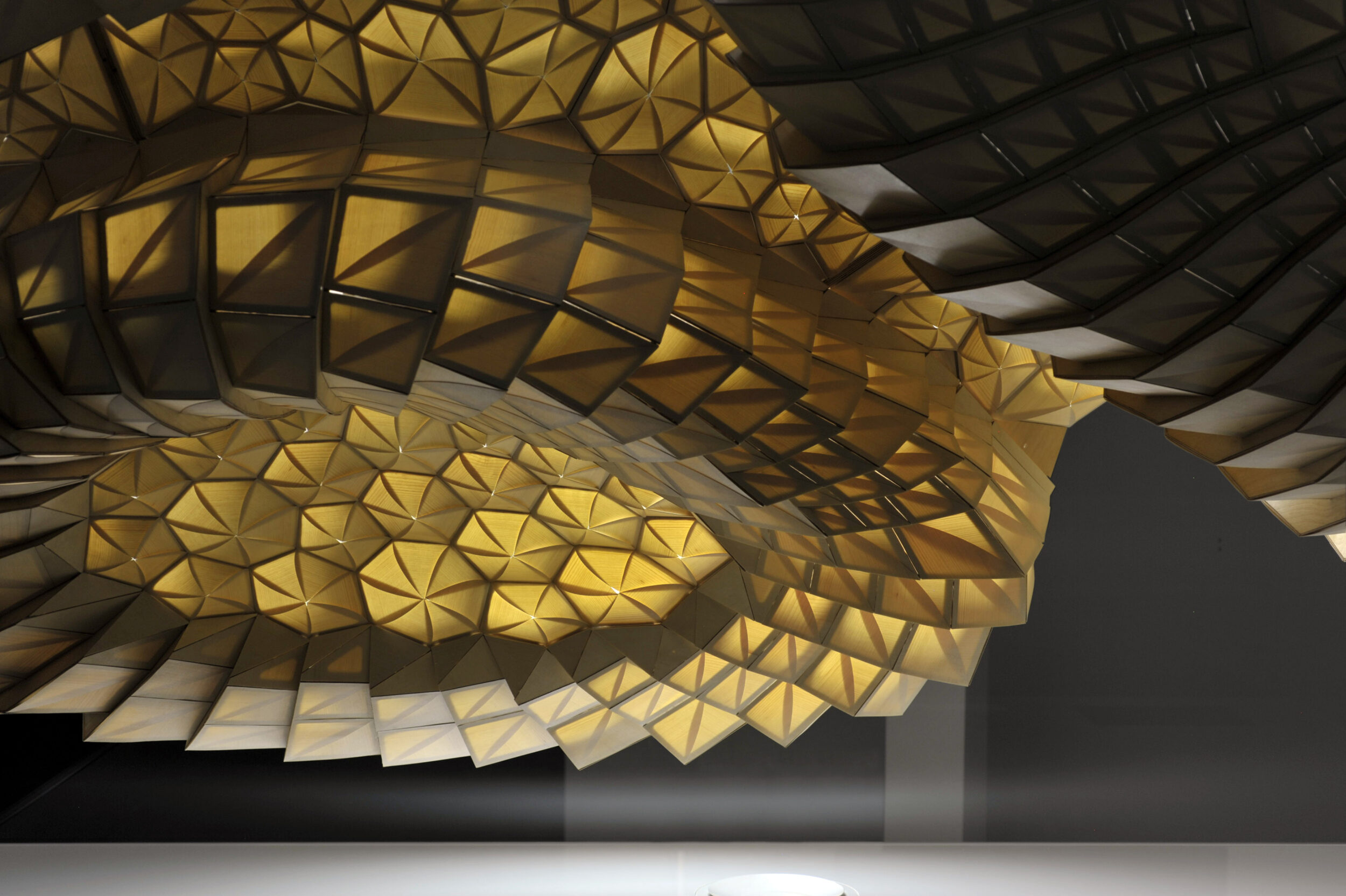

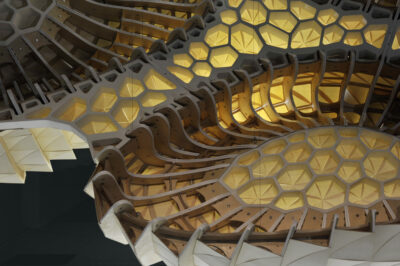

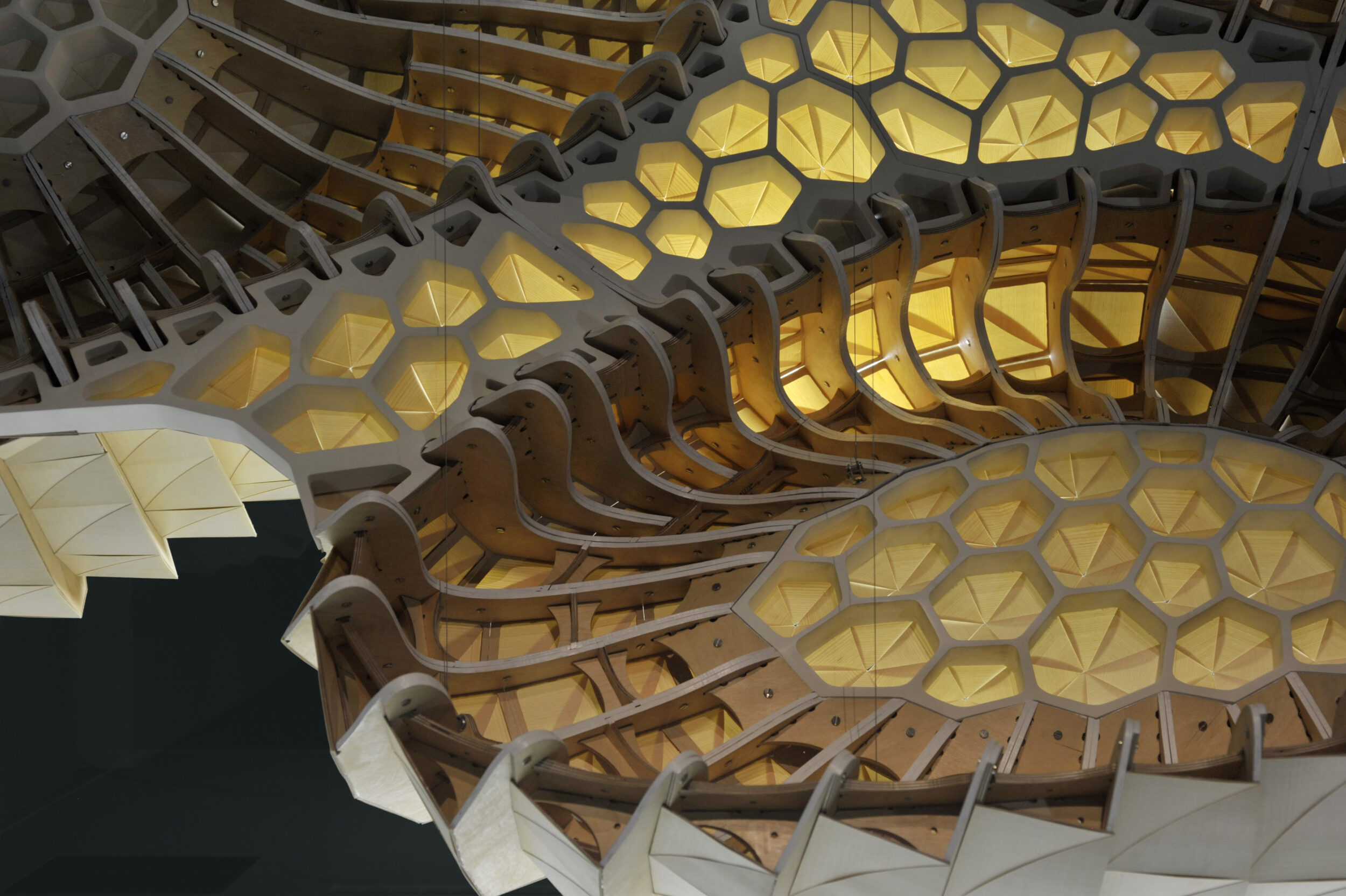

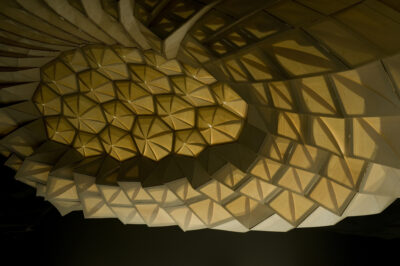

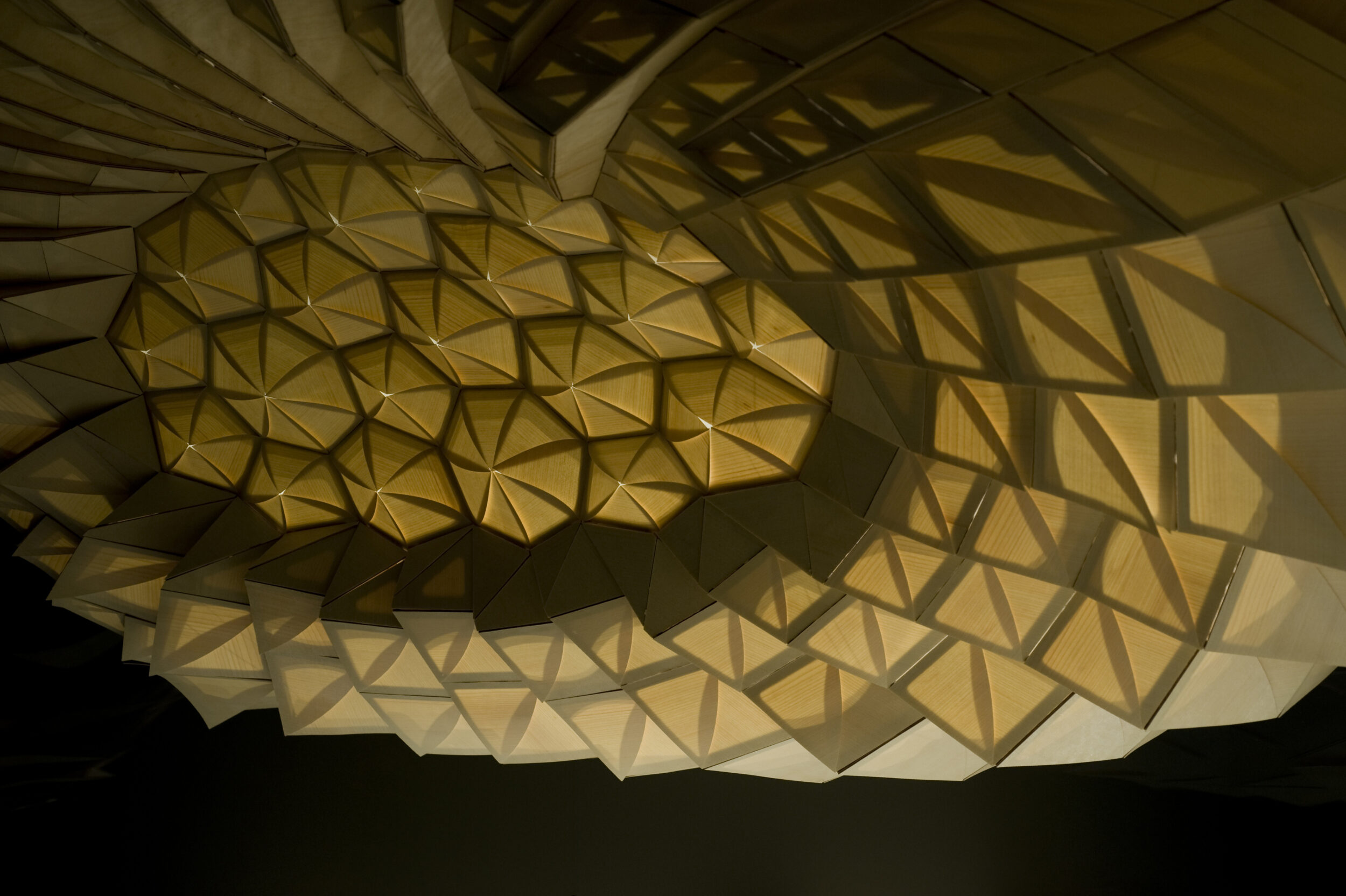

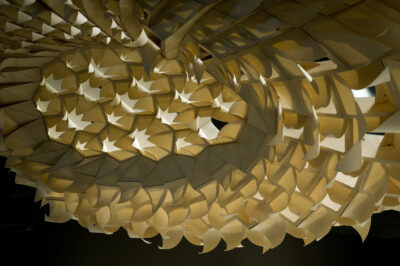

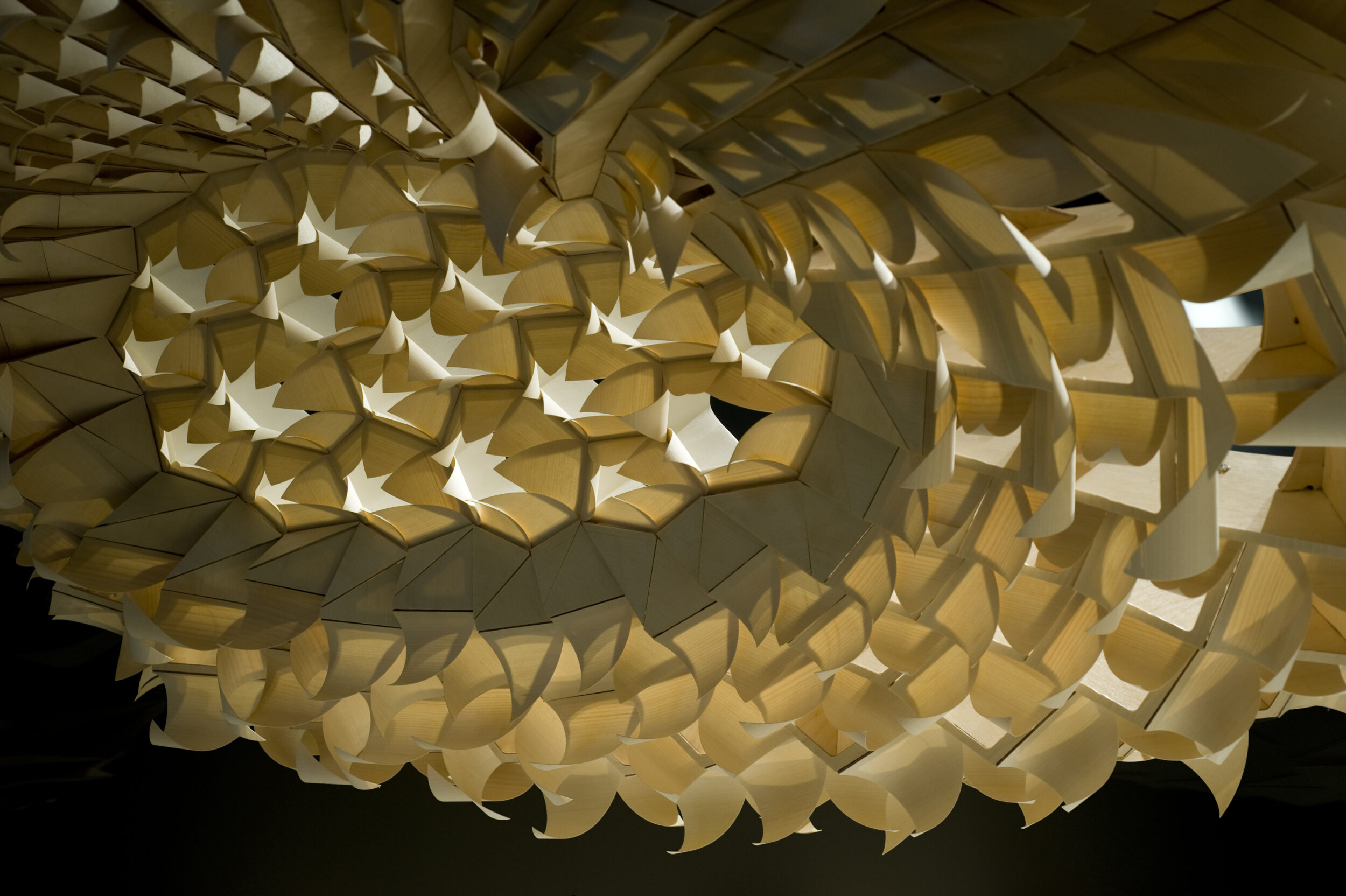

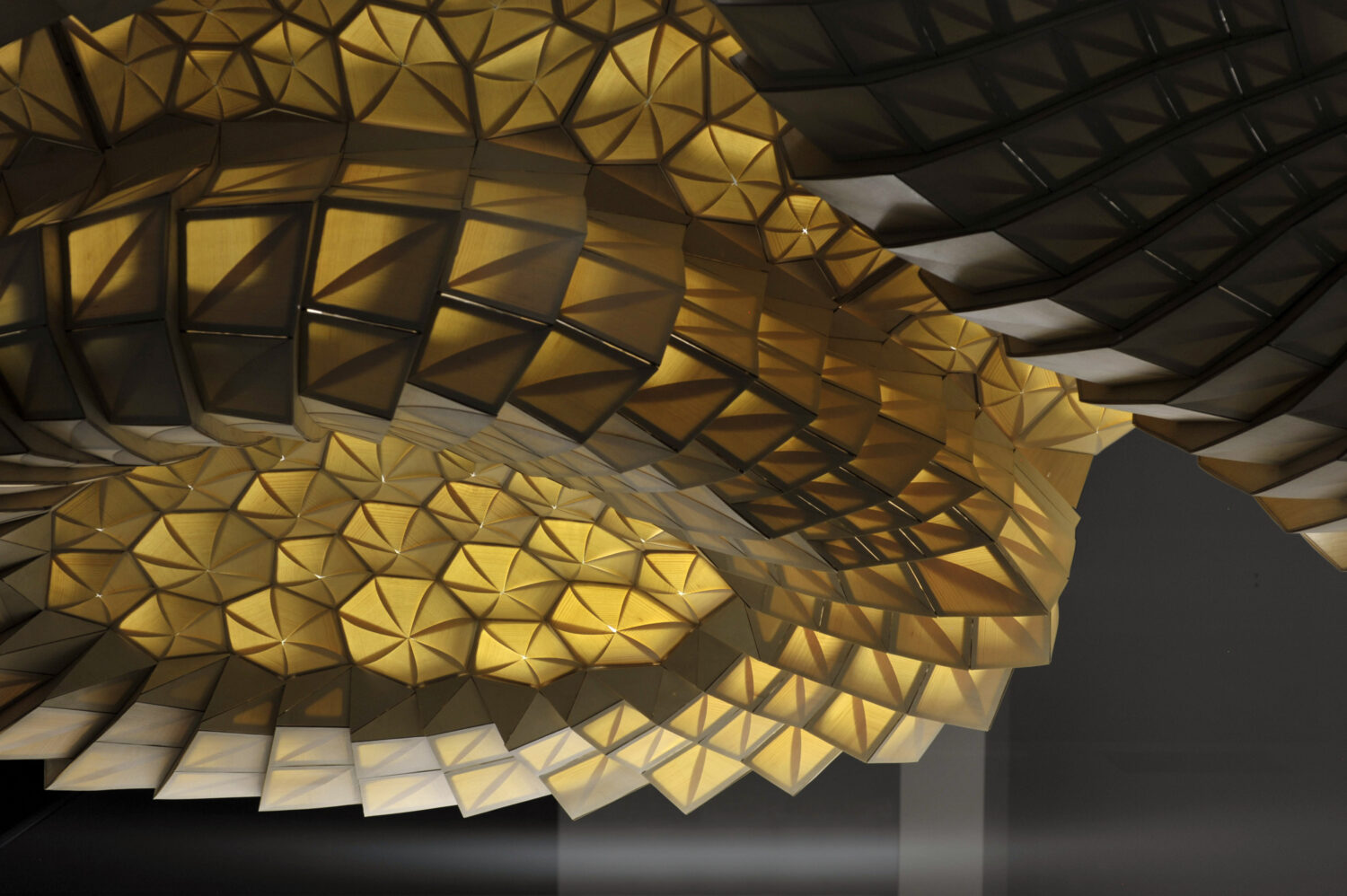

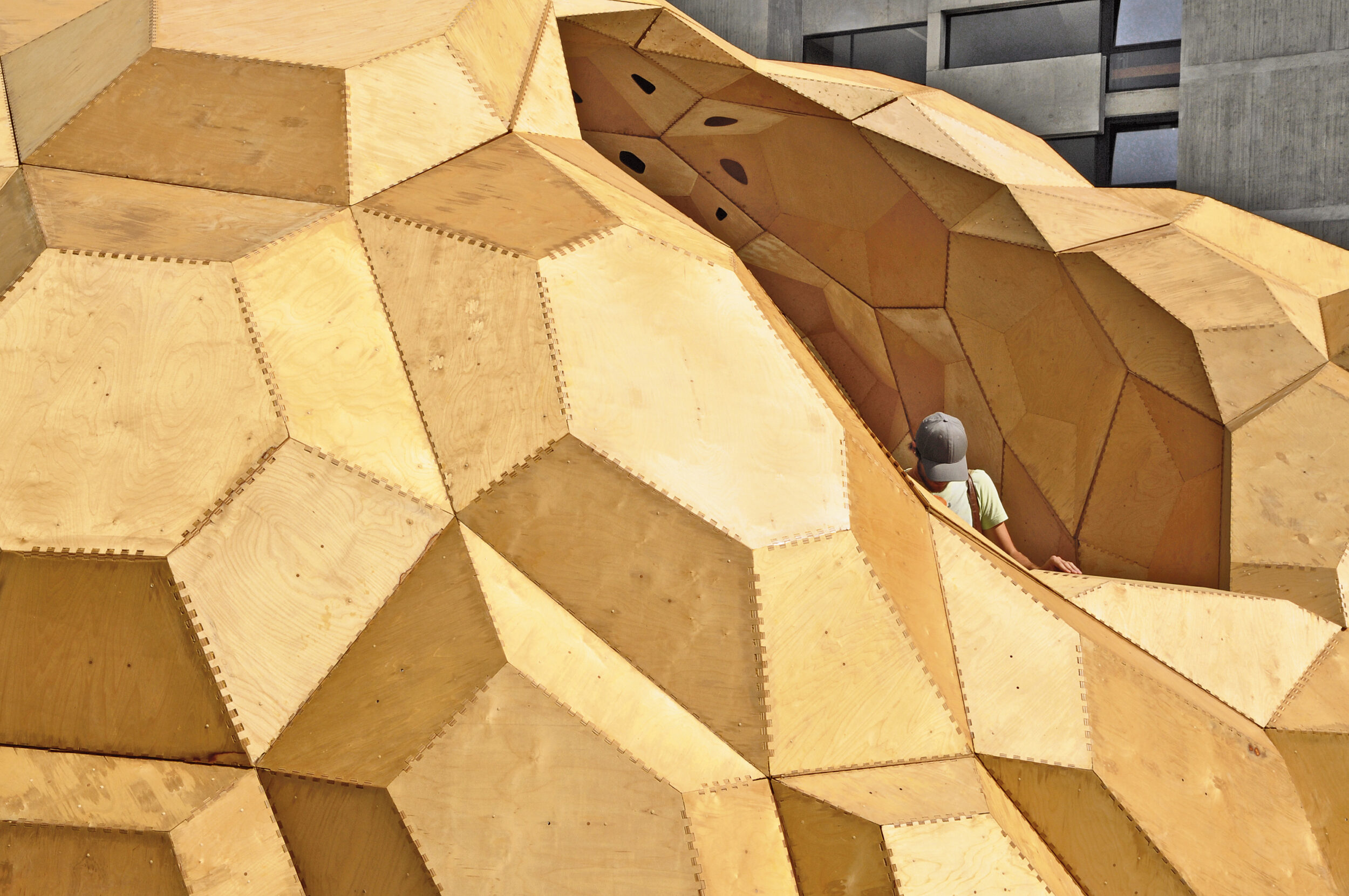

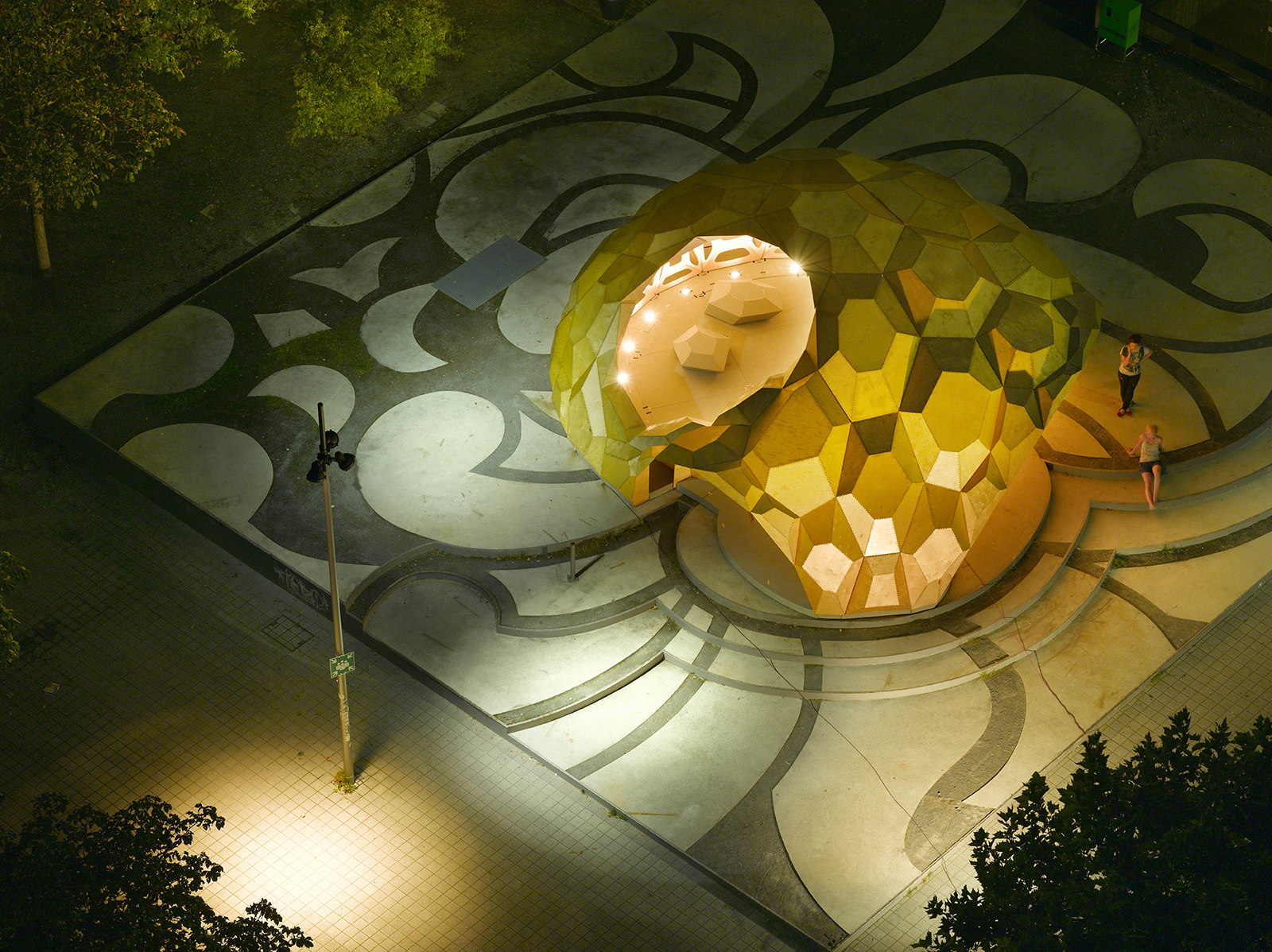

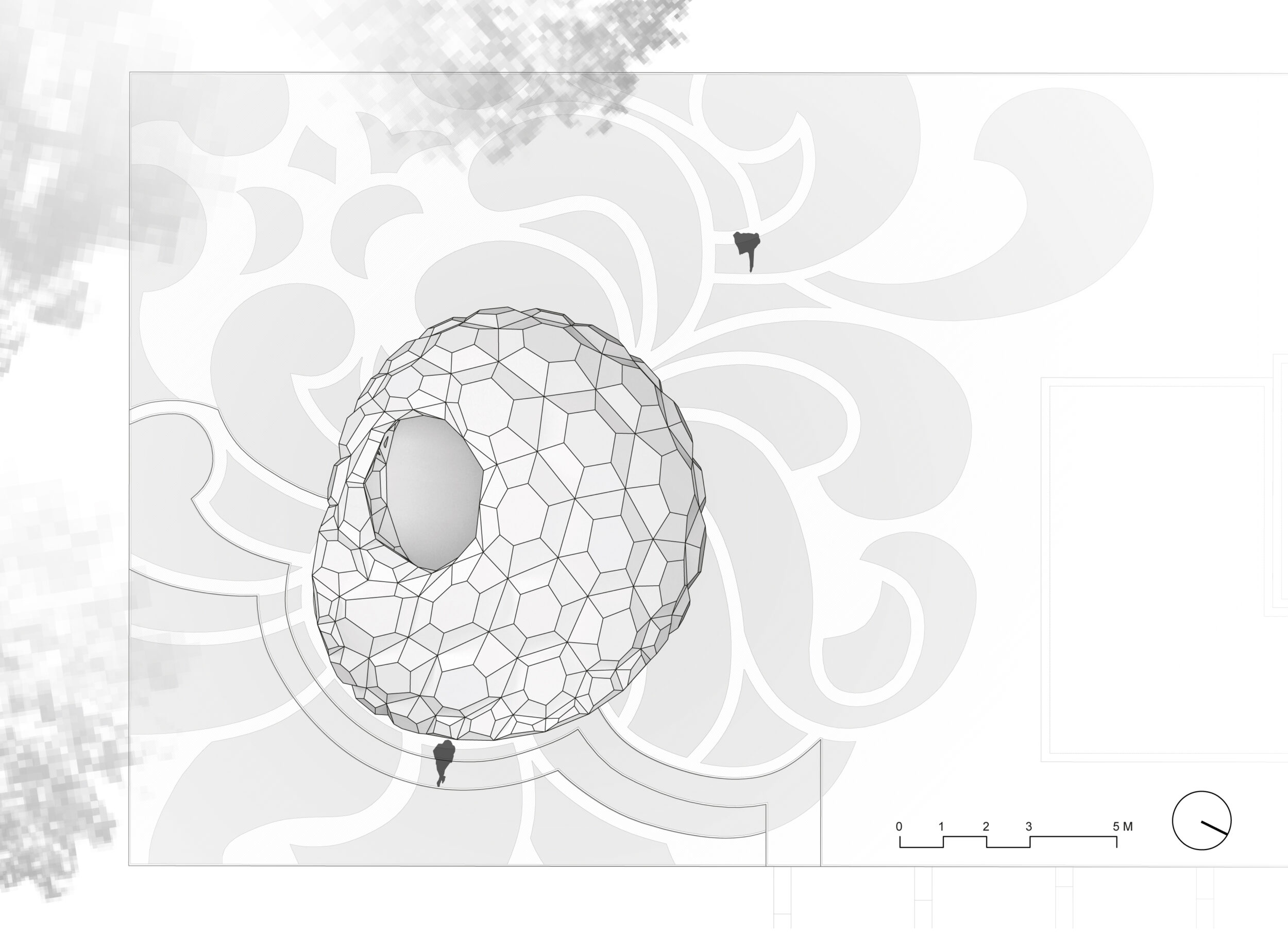

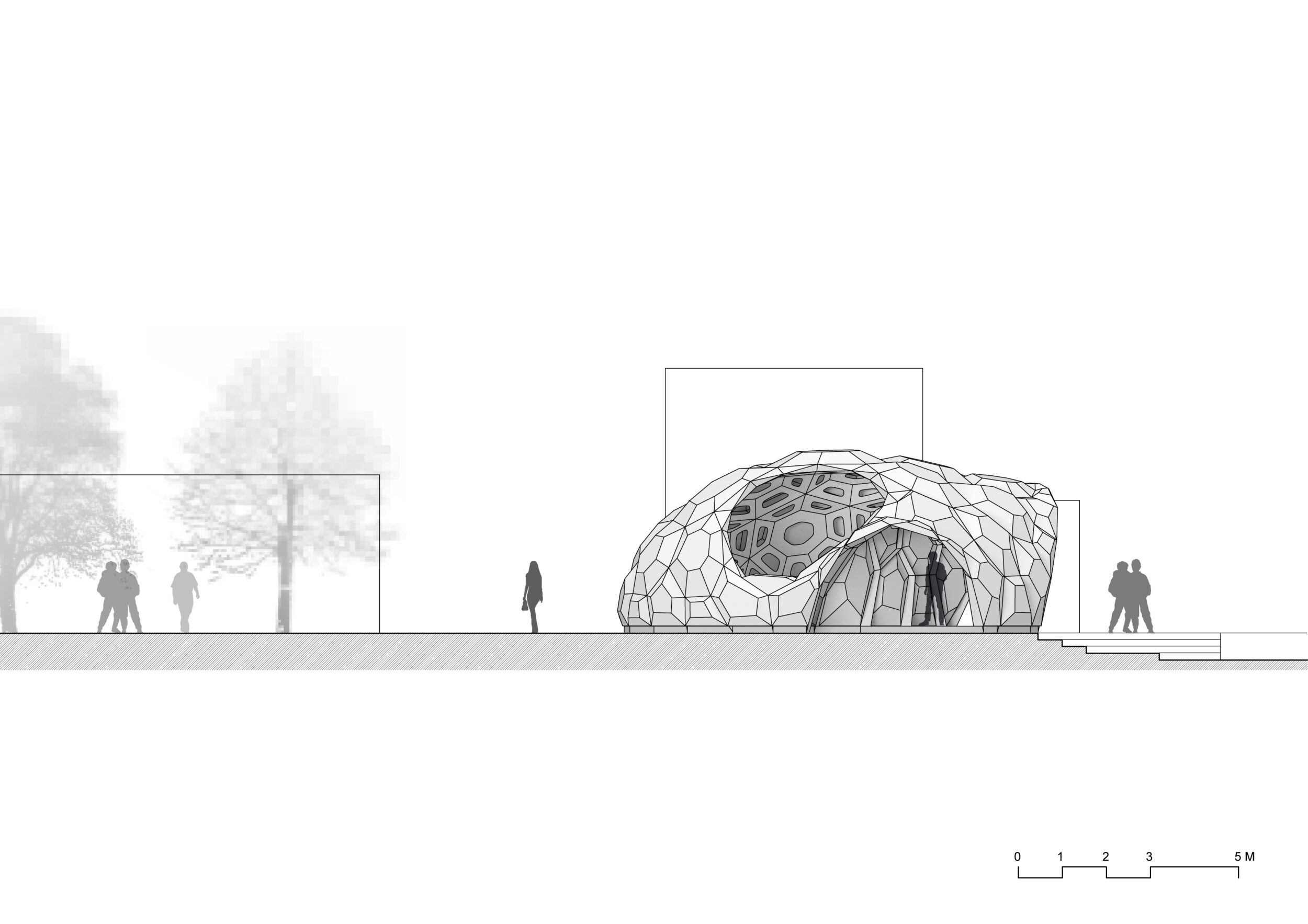

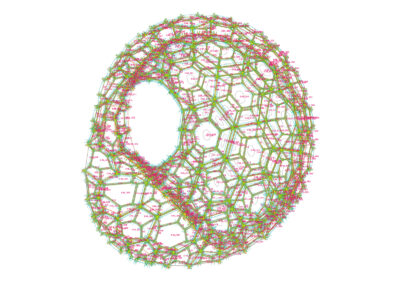

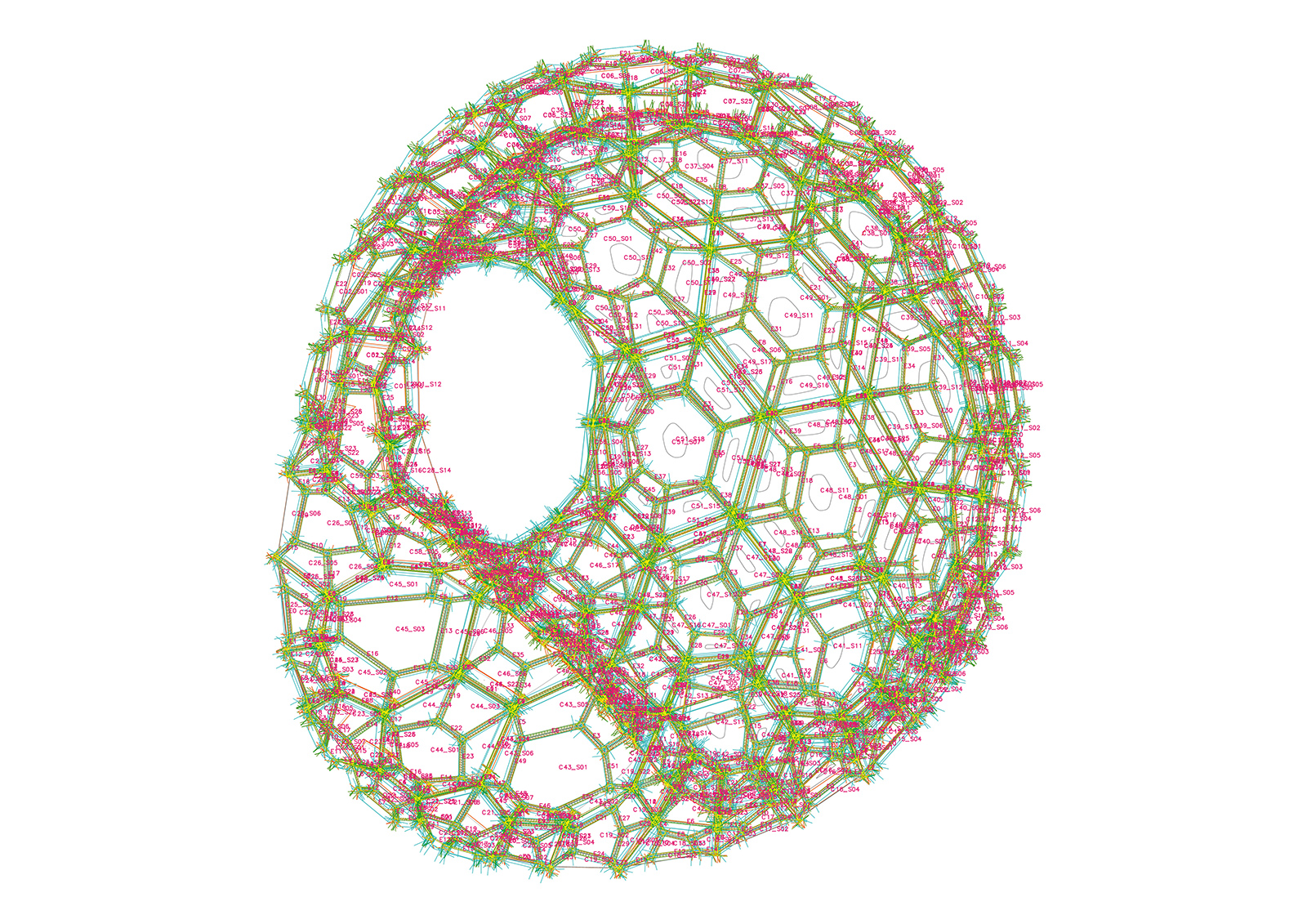

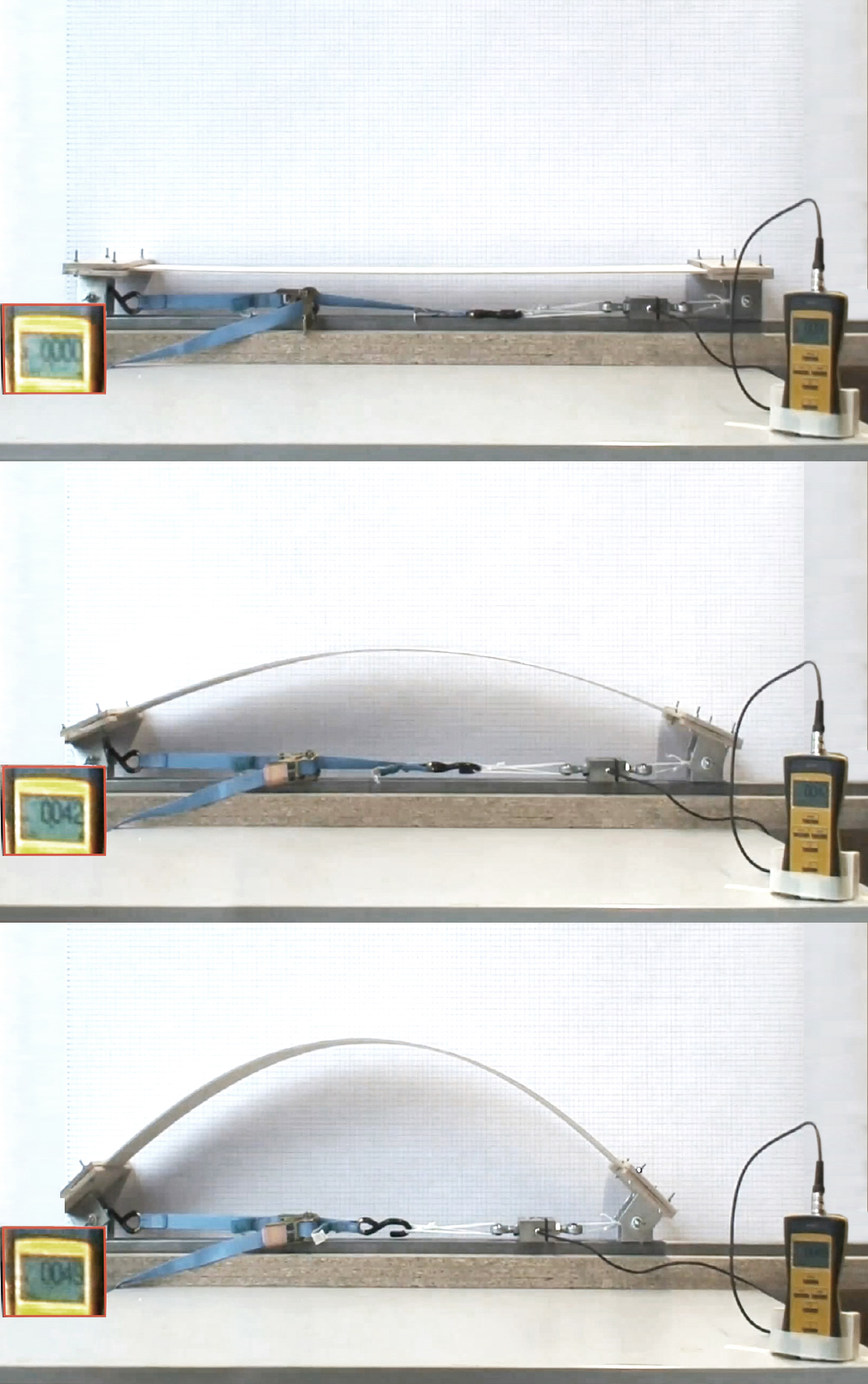

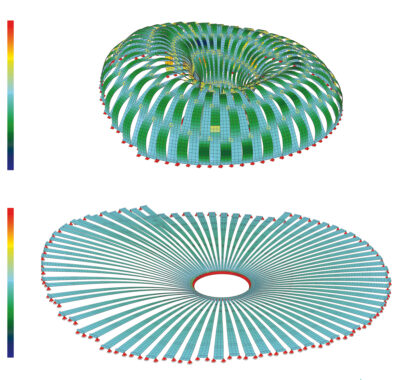

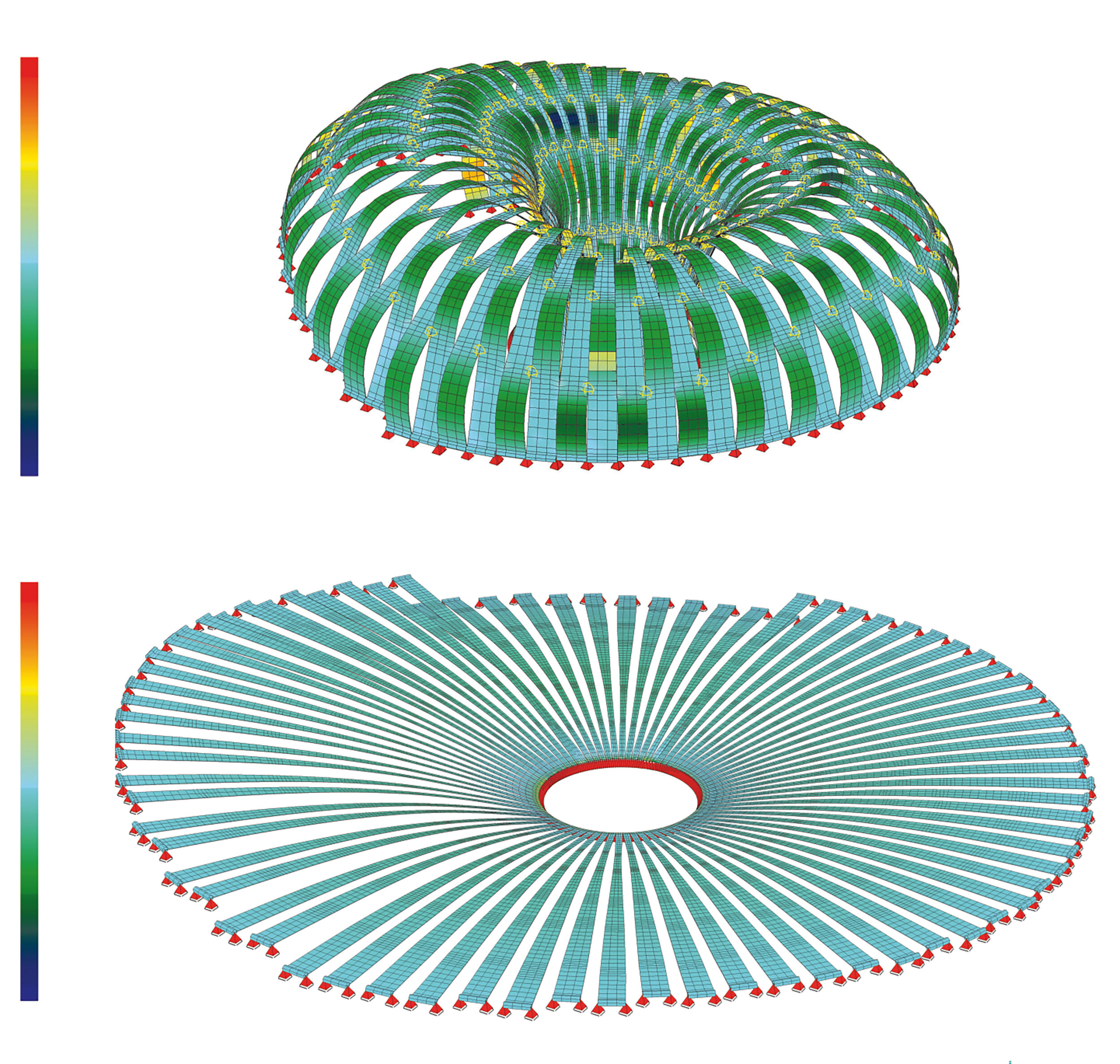

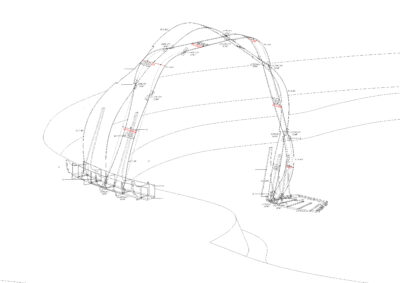

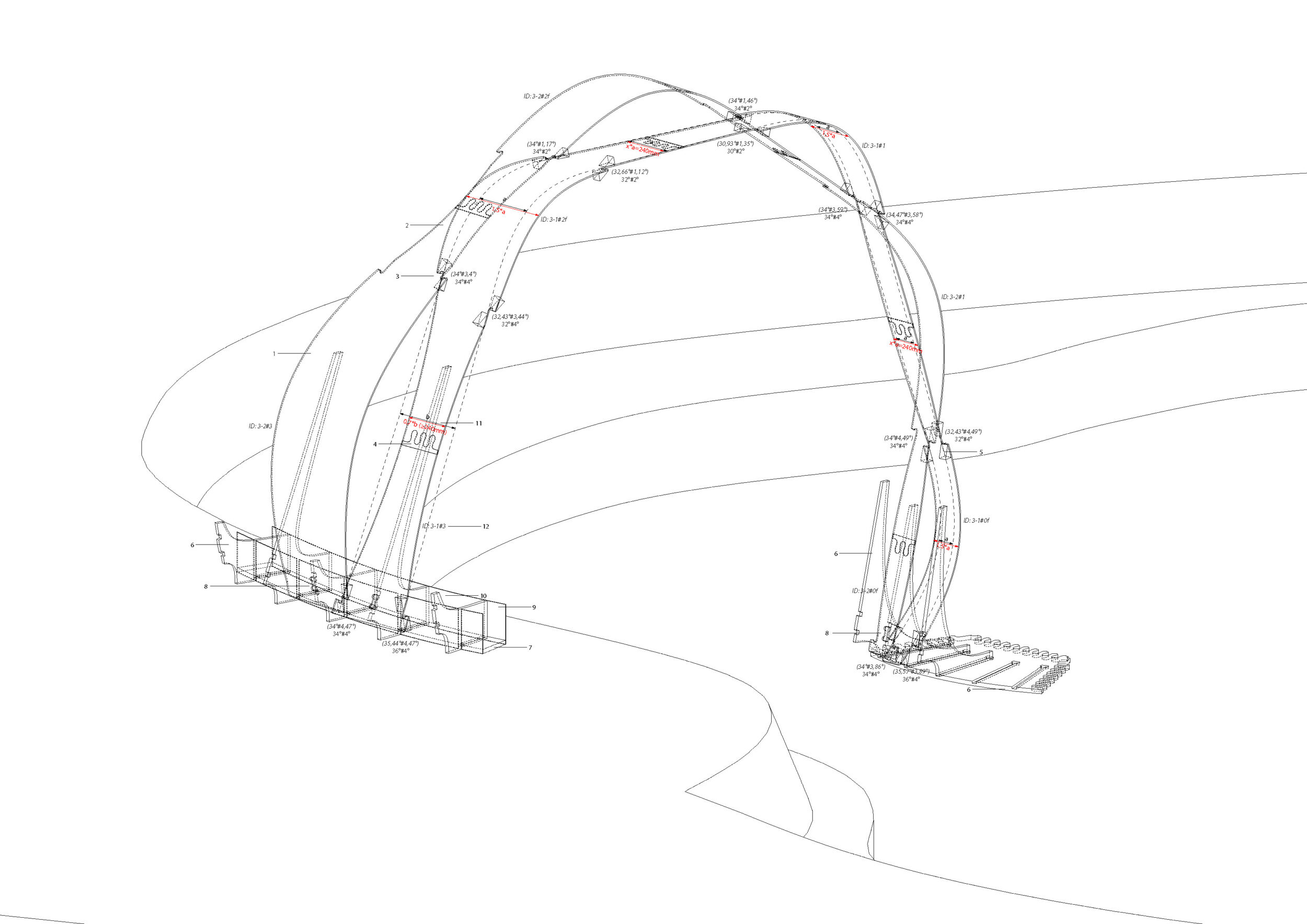

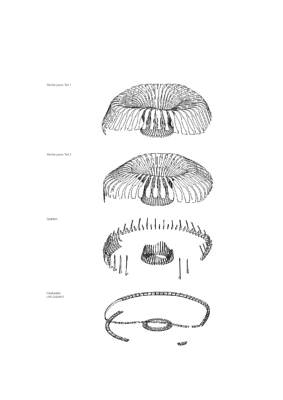

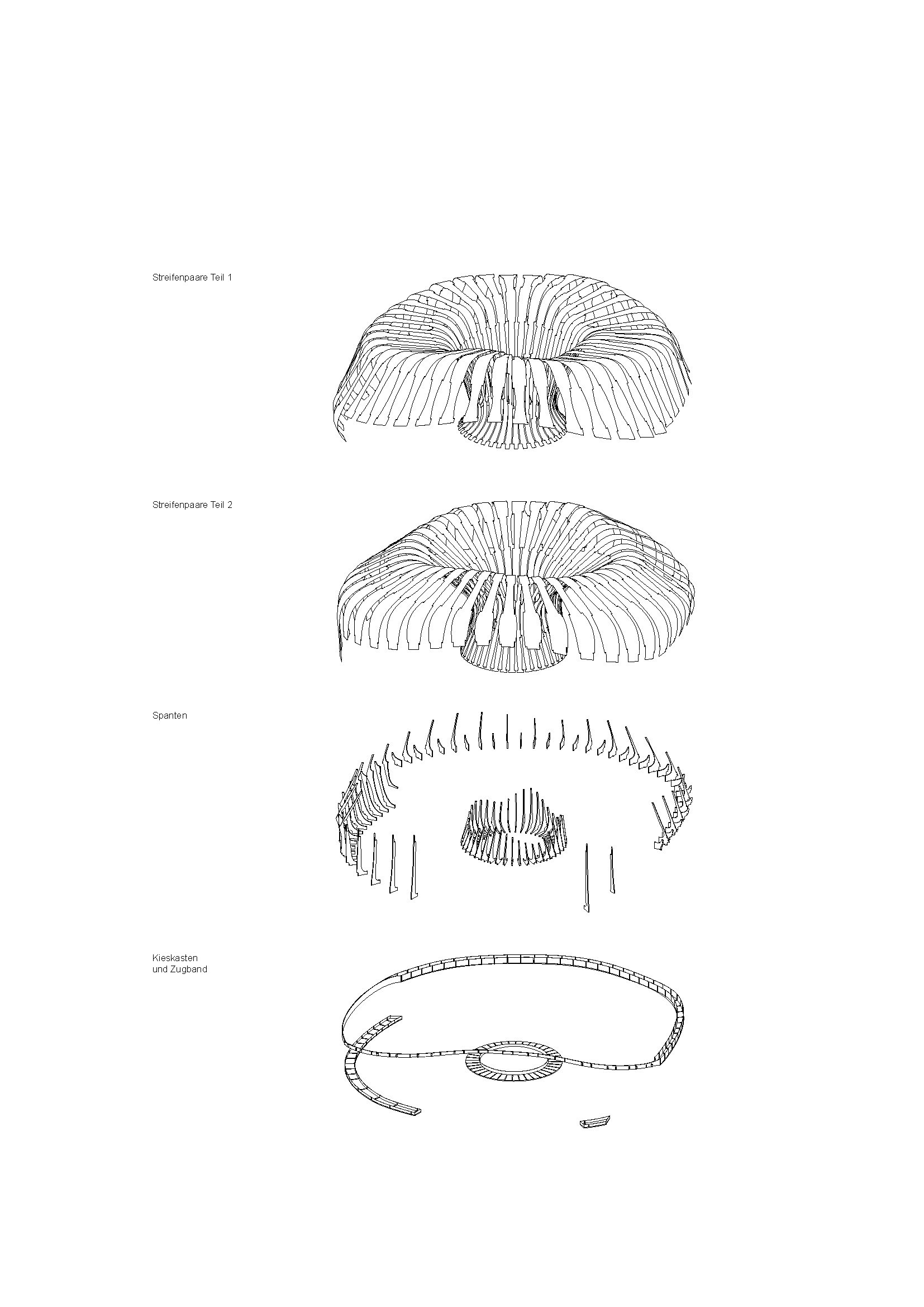

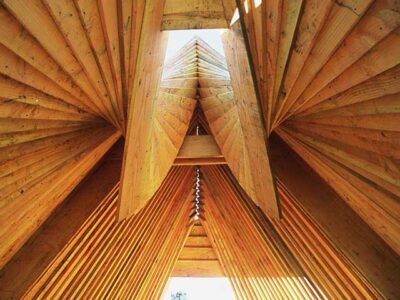

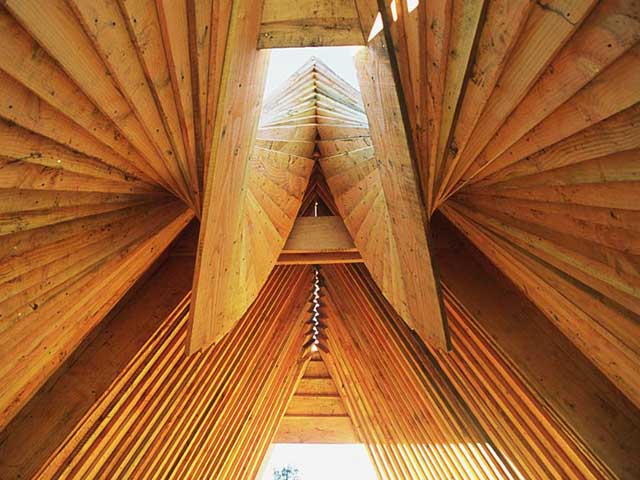

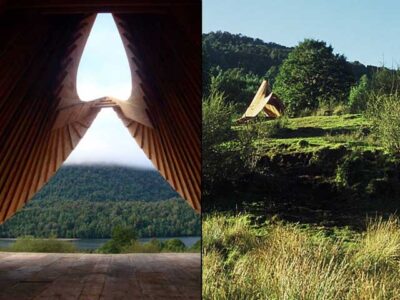

The Hybrid Flax Pavilion constitutes a central exhibition building on the grounds of the Landesgartenschau, located on the winding banks of the recently revitalised Argen River. The pavilion showcases a novel wood-natural-fibre hybrid construction system developed by the Cluster of Excellence »Integrative Computational Design and Construction for Architecture« (IntCDC) at the University of Stuttgart, as an alternative to conventional building methods. The unique hybrid system combines thin cross-laminated timber with robotically wound flax fibre bodies to create a novel, resource-efficient building structure made from regional, bio-based materials with a distinct local connection. Flax was historically processed in the local textile industry, whose old spinning mill was renovated as part of the Landesgartenschau. The pavilion’s gently undulating roof, together with its circular floor plan and centrally located climate garden, creates an exhibition space that seamlessly integrates into the surrounding landscape. The geothermally activatable floor slab made of recycled concrete provides year-round comfortable use of the permanent building.

For a detailed description and more images please view:

https://www.icd.uni-stuttgart.de/projects/hybrid-flax-pavilion/

_________________

PROJECT PARTNERS

Cluster of Excellence IntCDC – Integrative Computational Design and Construction for Architecture, University of Stuttgart

ICD Institute for Computational Design and Construction

Prof. Achim Menges, Rebeca Duque Estrada, Monika Göbel, Harrison Hildebrandt, Fabian Kannenberg, Christoph Schlopschnat, Christoph Zechmeister

ITKE Institute for Building Structures and Structural Design

Prof. Dr. Jan Knippers, Tzu-Ying Chen, Gregor Neubauer, Marta Gil Pérez, Valentin Wagner

with support of: Daniel Bozo, Minghui Chen, Peter Ehvert, Alan Eskildsen, Alice Fleury, Sebastian Hügle, Niki Kentroti, Timo König, Laura Marsillo, Pascal Mindermann, Ivana Trifunovic, Weiqi Xie

Landesgartenschau Wangen im Allgäu 2024

Karl-Eugen Ebertshäuser, Hubert Meßmer

Stadt Wangen im Allgäu

HA-CO Carbon GmbH

Siegbert Pachner, Dr. Oliver Fischer, Danny Hummel

STERK abbundzentrum GmbH

Klaus Sterk, Franz Zodel, Simon Sterk

FoWaTec GmbH

Sebastian Forster

Biedenkapp Stahlbau GmbH

Stefan Weidle, Markus Reischmann, Frank Jahr

Harald Klein Erdbewegungen GmbH

PROJECT COLLABORATIONS

Scientific Collaboration:

IntCDC Large Scale Construction Laboratory

Sebastian Esser, Sven Hänzka, Hendrik Köhler, Sergej Klassen

Further Consulting Engineers:

Belzner Holmes und Partner Light-Design

Dipl.-Ing. (FH) Thomas Hollubarsch, Victoria Coval

BiB Concept

Dipl.-Ing. Mathias Langhoff

Collins+Knieps Vermessungsingenieure

Frank Collins, Edgar Knieps

Moräne GmbH – Geotechnik Bohrtechnik

Luis Ulrich M.Sc.

Spektrum Bauphysik & Bauökologie

Dipl.-Ing. (FH) Markus Götzelmann

wbm Beratende Ingenieure

Dipl.-Ing. Dietmar Weber, Dipl.-Ing. (FH) Daniel Boneberg

lohrer.hochrein Landschaftsarchitekten DBLA

Building Approval:

Landesstelle für Bautechnik

Dr. Stefan Brendler, Dipl.-Ing. Steffen Schneider

Proof Engineer

Prof. Dr.-Ing. Hans Joachim Blaß, Dr.-Ing. Marcus Flaig

Versuchsanstalt für Stahl, Holz und Steine, Karlsruhe Institute of Technology (KIT)

Prof. Dr.-Ing. Thomas Ummenhofer, Dipl.-Ing. Jörg Schmied

MPA Materials Testing Institute, University of Stuttgart

Melissa Lücking M.Sc., Dipl.-Ing (FH) Frank Waibel

Construction Collaboration

ARGE- Leistungsbereich Wärmeversorgungs- und Mittelspannanlagen

Franz Miller OHG

Stauber + Steib GmbH

PROJECT SUPPORT:

DFG German Research Foundation

Ministerium für Ernährung, Ländlichen Raum und Verbraucherschutz Baden-Württemberg

Bioökonomie Baden-Württemberg: Forschung- und Entwicklung (FuE) Förderprogramm »Nachhaltige Bioökonomie als Innovationsmotor für den Ländlichen Raum«

Holz Innovativ Programm (HIP), Ministerium für Ernährung, Ländlichen Raum und Verbraucherschutz Baden-Württemberg

IFB Institute of Aircraft Design, University of Stuttgart

ISW Institute for Control Engineering of Machine Tools and Manufacturing Units, University of Stuttgart