IBA Timber Prototype House: Photographs by Thomas Müller

IBA Timber Prototype House: Process Images

by ICD University of Stuttgart / IBA Thüringen / Jade Hochschule Oldenburg

IBA TIMBER PROTOTYPE HOUSE

Log Cabin Digital – International Building Exhibition (IBA) Thueringen, Germany 2019

The IBA Timber Prototype House presents a new take on micro-architecture. Effectively a log cabin turned on its side, it combines the benefits of traditional low-cost timber construction with advances in computational design and fabrication technologies. The project explores a novel solid timber building system to economically create environmentally sound, architecturally expressive, mono-material building envelopes. In contrast to the horizontal stacking of typical log construction, here the solid timber elements are arranged as staggered upright frames. Thus the vertical elements are oriented in the strong direction of the wood which allows for sawing slits in the solid timber without comprising its structural capacity. These thin slits serve as stress-relief cuts, which prevent the solid timber from splitting. This ensures dimensional stability and airtightness, both significant issues in traditional log construction. At the same time, the slits are utilized as dead-air chambers, reducing thermal conductivity and increasing the insulation values of the material. Digital fabrication is employed to produce high-precision, airtight joints for connecting the timber elements without the need for any metal fasteners or adhesives. The resulting, highly sustainable mono-material building system acts as structure, enclosure and insulation, achieving compliance with stringent German energy saving standards. The fully integrated computational design and fabrication approach allows for gently twisting and curving walls and ceilings. They not only offer the possibility to maximize the ratio between available space and envelope surface, but also intensify the architectural experience of this unique micro-house.

MONO-MATERIAL WOOD CONSTRUCTION

Wood is a renewable resource and a construction material with unmatched ecological virtues. It encapsulates atmospheric carbon in long lasting building structures, requires very little energy and resources for processing, and can often be obtained locally. Conventional building systems have a vast array of different materials embedded in them, which often have very high embedded energy costs and are difficult to separate for recycling. In contrast, this research draws on traditional joinery, and a system was developed that relies purely on wood elements for structural connections and airtight enclosure, minimizing system layers and ensuring easy disassembly for end-of-life recycling. Furthermore, the project sources all the wood from within the state of Thüringen, where the demonstrator was built, allowing the team to minimize the embodied energy costs associated with moving materials over transportation networks. The construction system is envisioned as a contemporary timber blockhouse, which uses stacked timber beams to create vertical and horizontal elements. While the system draws inspiration from vernacular construction, it simultaneously addresses issues found in both historical and conventional construction systems by combining traditional joinery techniques with advanced digital modeling and high-precision fabrication.

INTEGRATED BUILDING SYSTEM

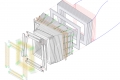

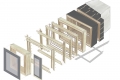

Research innovations make improvements on both traditional and conventional construction practices. The profile of the base timber module was designed to implement discrete performative zones to achieve efficient thermal performance, high structural capacity, and airtight enclosure. In contrast to the horizontal stacking of typical log construction, here the solid edged timber elements are arranged as upright frames. Thus the vertical elements are oriented in the strong direction of the wood for optimal structural performance. This also leaves internal volume that can accommodate sawn slits in the timber. These smart slits serve to relieve internal stresses, which prevent the solid timber from splitting and warping, thus ensuring its dimensional stability and tightness. Simultaneously the slits function as dead-air chambers, reducing thermal conductivity and increasing the insulation values of the material. Digital fabrication is employed to produce high precision, airtight joints for connecting the timber elements without the need for any metal fasteners or adhesives. The resulting, highly sustainable mono-material building system achieves structure, enclosure and insulation. No additional insulation is required to achieve a U-value of 0,20 W/(m²K), which complies with stringent German energy saving standards.

COMPUTATIONAL DESIGN AND FABRICATION

The novel approach to square edged timber construction also allows designers to overcoming the rectangular characteristics of most micro-architecture. Fully integrated computational design tools create a direct conduit from design geometry to machine code data for driving automated fabrication tools. Five-axis CNC milling allows precise variation in joinery details. This geometric variation creates shifts and offsets in adjacent beams to follow the gently twisting and curving walls and ceilings of the designed building envelope. The digital tools not only offer the possibility to maximize the ratio between available space and envelope surface, but also intensify the architectural experience of this unique structure. By developing a complete, computational, design-to-fabrication workflow, researchers were able to rapidly iterate on geometric forms and instantly understand the consequences of design decisions with respect to building metrics, fabrication time, and material usage. This represents a significant step in the integration of design, engineering, construction, and material sourcing, improving on standard architecture practices.

THE IBA TIMBER PROTOTYPE HOUSE

The result of the research is a small, free-standing, fully enclosed micro-house. The gracefully curving walls and roof are experienced both internally and on the exterior of the demonstrator, and the ends are capped with dramatic windows looking out on the historic Egon-Eiermann-Bau. The prototype was designed as a fully furnished micro-house, and is ready to be equipped with all necessary amenities for compact living. The International Building Exhibition (IBA) Thüringen will use it as a meeting and exhibition space, as well as an exhibit itself, proving the possibility for innovative design research that is still based on regional materials, knowledge, industry and labor. Despite the cold winters in eastern Germany, simulations indicate that the demonstrator should perform up to Passiv Haus standards, a rigorous set of building physics standards that minimize energy use in buildings. The demonstrator itself will also be closely monitored to verify test results in real life conditions.

The Timber Prototype House is a project of the International Building Exhibition (IBA) Thüringen and can be visited in Apolda, Thüringen.

PROJECT TEAM

ICD Institute for Computational Design

Prof. A. Menges (PI), Oliver Bucklin, Oliver David Krieg, Victor Rodriguez

Jade Hochschule Oldenburg

Hans Drexler, Marie Deilmann, Geronimo Bujny, Anna Bulavintseva

Internationale Bauaustellung Thüringen

Dr. Marta Doehler-Behzadi, Tobias Haag

PROJECT FUNDING

Bundesinstitut für Bau-, Stadt- und Raumforschung

Forschungsinitiative Zukunft Bau

MAIN SPONSORS

ThüringenForst

Rettenmeier Holding AG

CO-OPERATION AND INDUSTRY PARTNERS

Klima und Umweltlabel Holz von Hier

Georg Ackermann GmbH

Universal Holzbau GmbH

Glaskontor Erfurt GmbH

Bauhaus-Universität Weimar

Ingenieurbüro Matthias Münz

Nils Holger Moormann GmbH

hofmann+löffler creativeinrichtungen GmbH

Stadt Apolda