Differentiated Wood Lattice Shell

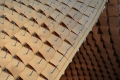

Until today, the geometry of lattice shells derived through form finding processes has been based on the bending behavior of wooden elements with a uniform cross section. The first research objective of this project was to extend the range of possible lattice geometries based on the bending behavior of wooden elements with varying cross-sectional dimensions along their length. Thus, a robotic water jet cutting technique was developed, that gradually reduces the cross section of such elements without damage to the perimeter fibres, reducing the risk of splitting during the subsequent bending process. Through the related fabrication variables, each wooden element’s stiffness can now be adjusted by locally reducing its structural depth. This differentiation of the cross section allowed building up an entire catalogue of possible bending behavior of the lattice elements, which was computationally established based on a large number of physical tests. This information was embedded in computational design tool for form-finding the lattice shape in relation to the differential bending behavior of its members, which also provides the fabrication data for constructing the initially planar grid.

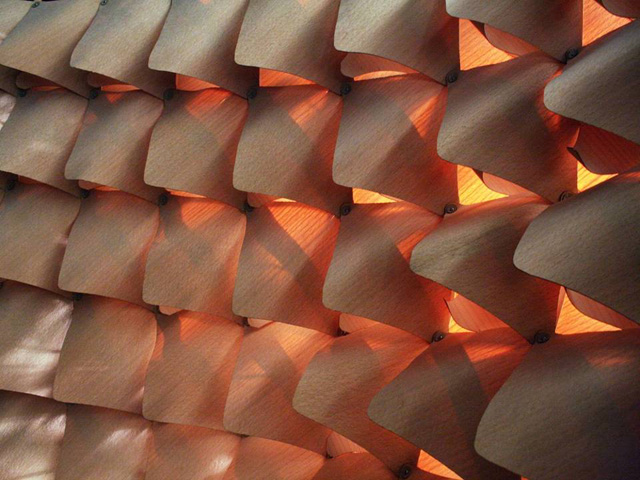

The second research objective of this project was developing an alternative way of erecting such a flat lattice without the need for additional scaffolding or hoists. A stressed wooden skin was developed, which gradually forces the lattice into its structurally stable, double curved state by the local actuation of each skin element A local actuator element was developed consisting of two skin panels with additional diagonal members and a variable spacer bolt that can adjust the diagonal distance of each respective grid field. Based on detailed studies of the achievable actuation force and related element variables such as size, thickness and fibre orientation, actuator locations and required torque, a computational tool for deriving the related actuation protocol was developed and tested in a full scale prototype.

For the prototype construction, the robotically fabricated members with varying cross-section, together with the laser cut skin elements, are assembled as flat lattice. But once the actuators are adjusted according to the digitally derived protocol the lattice raises into its computationally defined, structurally stable, double curved form. Integrating the critical material characteristics and behavior of wood in the computational design process for both the local stressed skin actuators and the non-uniform bending behavior of elements with locally reduced stiffness allows for a more specific articulation of the lattice geometry. In the resulting structure, the differentiated transparency and articulation of the skin registers the embedded forces, which maintain equilibrium in the very thin, non-uniformly bend lattice.

Performative Wood Studio (Visiting Prof. A. Menges)

Jian Huang and Minhwan Park, Harvard University Graduate School of Design, 2009