Translucent Lamination

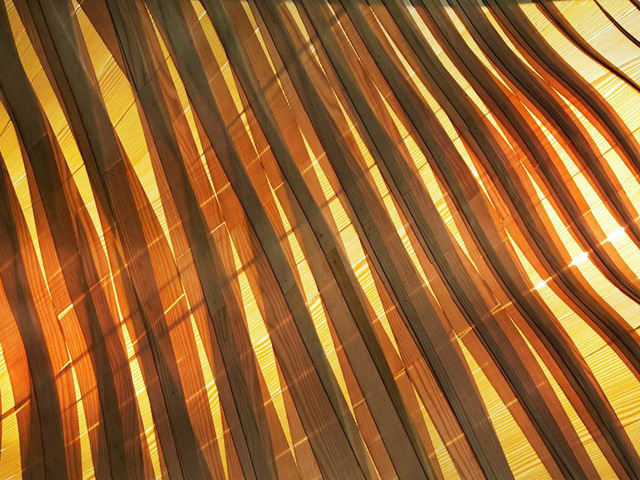

As a material approach shown throughout wood’s cellular structure, the translucent quality can be instrumentalized through repetitive pattern orchestration. An interest in misalignment of these orchestrated patterns and their relationship is synchronously investigated together with structural stability of a surface to design an alternative architectural surface, reacting to various lighting conditions. The micro-composition of wood veneer negotiates directionality of the wood grain allowing for layers of densities further accentuating the translucent notion of the material. Additionally, the grain direction of the layers produces, on the micro-scale, an essence of a moire patterning.

The relationship and organization of the matter within the wood make up – latewood and the earlywood – is what constitute the variation of translucency within a thin sheet of veneer. In order to investigate the possible relationship of a desired percentage of light transmission through the wood veneered surface and the number of layers, the following parameters were tested physically: [i] Number of layers needed to stabilize a curvature along and again the grain [ii] Variation of light transmission (various numbers of layers, fixed distance) [iii] Variation of the d distance from the light source (fixed layers) [iv] Variation of fiber direction angle creating yet another layer (moire pattern) out of veneer layers, visible only when inspected from up close (two layers only, variation of one or two-layer rotation). The results of these empirical tests described above indicated and several additional variables such as edge condition, grain direction, structural stability of the architectural surface, gradient translucency, veneer strip width, and transition between layers were embedded in a computational design process that derives the layering patterns of the surface. To allow for orchestrated layering of veneer strips defined by Geodesic curves on the surface, a technique of vacuum pressed lamination was used to create a full scale prototype.

Performative Wood Studio (Visiting Prof. A. Menges)

Iva Kremsa, Harvard University Graduate School of Design, 2009