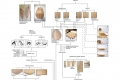

Multi-scalar Woven Wood Structure

This project examines the relationship between the digital and the physical in regards to woven surfaces, defining a set of parameters that take into account the material properties. The process for this project looked at woven systems as a series of parameters such as weave differentation, spacing, size, etc. The material properties of wood were also employed in the system, defining properties such as bending behavior and grain direction. These determined parameters were them input into a computational model that calculated fabrication information and templates using the specified properties of a given surface. The hypothesis for the project was that through utilizing the unique tensile capacity and bending ability of wood, a system can be created with double curvature to create a thin yet rigid structure. A woven system allows a framework in which the scale and relationship of the members can be varied to respond to local conditions while remaining continuous with the overall system. The material properties were combined with the logic of the system in a computational model that could use specific parameters to compute the information needed for the fabrication and assembly process. Within the inherent faceted curvature of this system, a variety of spaces were investigated; dividing, opening up to, and closing off from the space which surrounds it. In order to test the computational process a full scale prototype was constructed. The surfaces were assembled from computed flat elements which create the desired form from the differences in their shapes, creating curved surfaces from CNC cut flat elements without the need for formwork

Performative Wood Studio (Visiting Prof. A. Menges)

Ashley Merchant, Harvard University Graduate School of Design, 2009