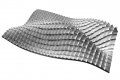

Responsive Surface Structure I

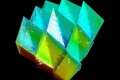

This research project explores the possibility of utilising the dimensional changes of wood induced by changes in relative humidity in the environment. The project aimed at developing a surface structure that adapts the porosity of its skin, and related cross-ventilation, in response to relative humidity without the need for any mechanical control devices. Here the response is triggered by the changes of moisture content of the material and actuated through related shape changes in a material element, which affects the structure’s degree of porosity.

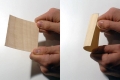

Initial experiments focused on the behaviour of veneer composite elements. Key design parameters, such as fibre orientation or the ratio of thickness, length and width, were tested in relation to the element’s response time to changes in moisture content and resultant shape change. An increase in relative humidity and related moisture content of the material causes the veneer elements to swell. As a result, and due to the fibrous restrictions, the surface expands mainly orthogonal to the main fibre direction. The ensuing gradual shape change opens a gap between the curving element and the substructure and thus increases the component’s degree of opening. The material’s hygroscopic capacity of absorbing and retaining moisture is fully reversible and, given an extreme change in relative humidity, pretty rapid as the shift from closed to fully open state takes less then 20 seconds. The innate material capacity of the developed component integrates humidity sensor, change actuator and porosity control element.

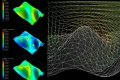

In order to account for the relation between individual components, their location within a larger system and the resultant micro- and macro- thermodynamic modulations the development of the global surface is based on a mathematical definition. This enables a computational, hygromorphic evolution in which manipulations to the local element set-up, regional component assemblies or the overall system are directly related to environmental modulations and vice versa. This feedback provides the relevant data for continuous parametric alterations of the computational model.

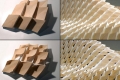

A functional, full scale prototype was constructed and tested. Once exposed to changes in relative humidity the opening and closure of each local component results in different degrees of porosity over time and across the surface, which is both structure and responsive skin. This high level of integration of form, structure and material performance enables a direct response to environmental influences with no need for additional electronic or mechanical control.

Department of Form Generation and Materialisation (Prof. Achim Menges)

Steffen Reichert, HFG Offenbach University of Art and Design, Germany, 2006-07